Jacking pipe joint safety protection device

A technology of safety protection device and pipe section, which is used in shaft equipment, shaft lining, tunnel lining, etc., can solve the problem of inability to provide strong protection for construction personnel in the pipe jacking, and achieve the effect of stable support and improved safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

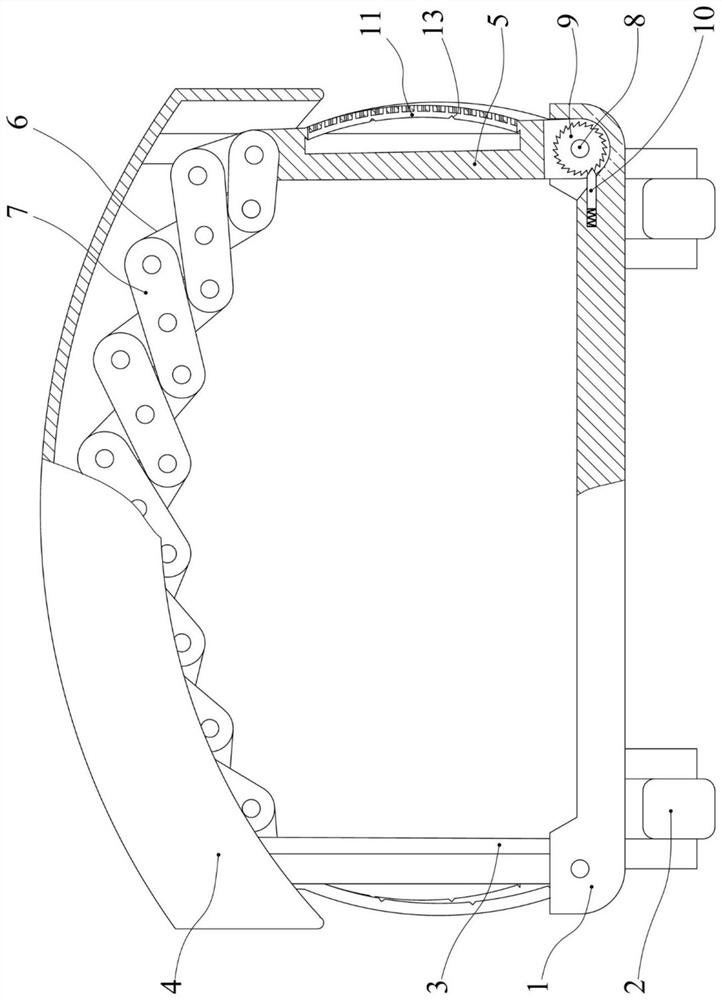

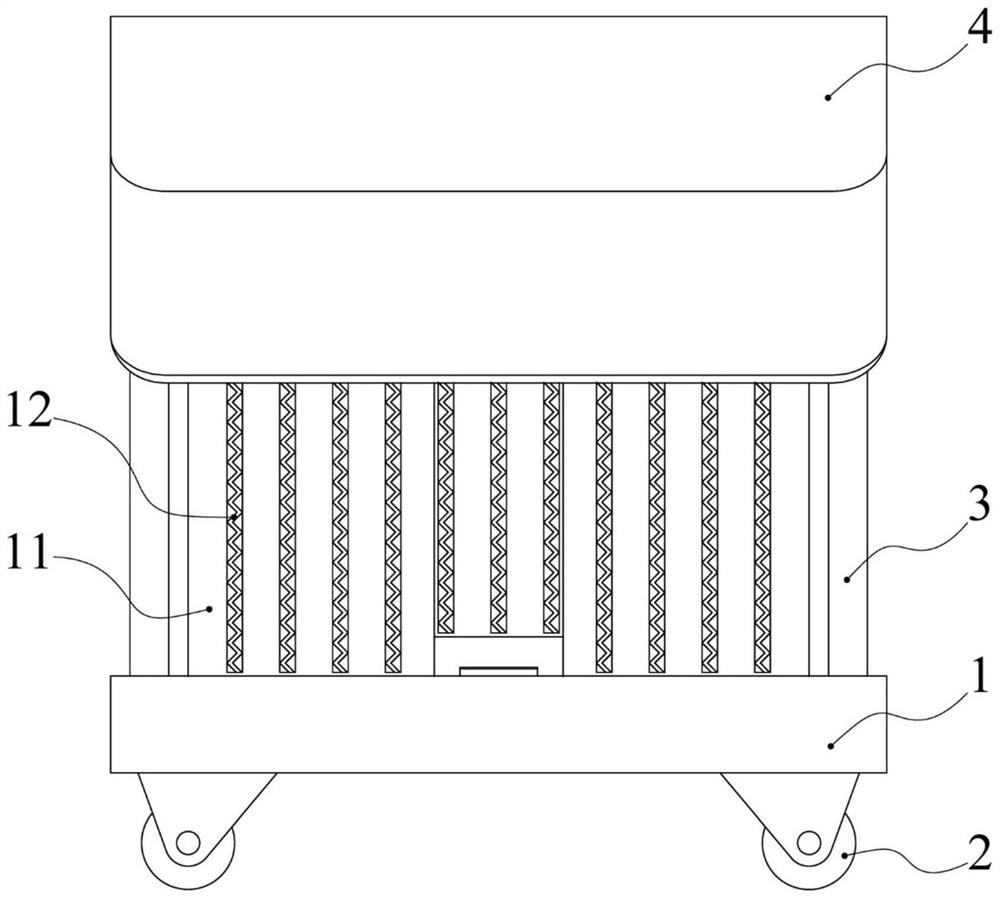

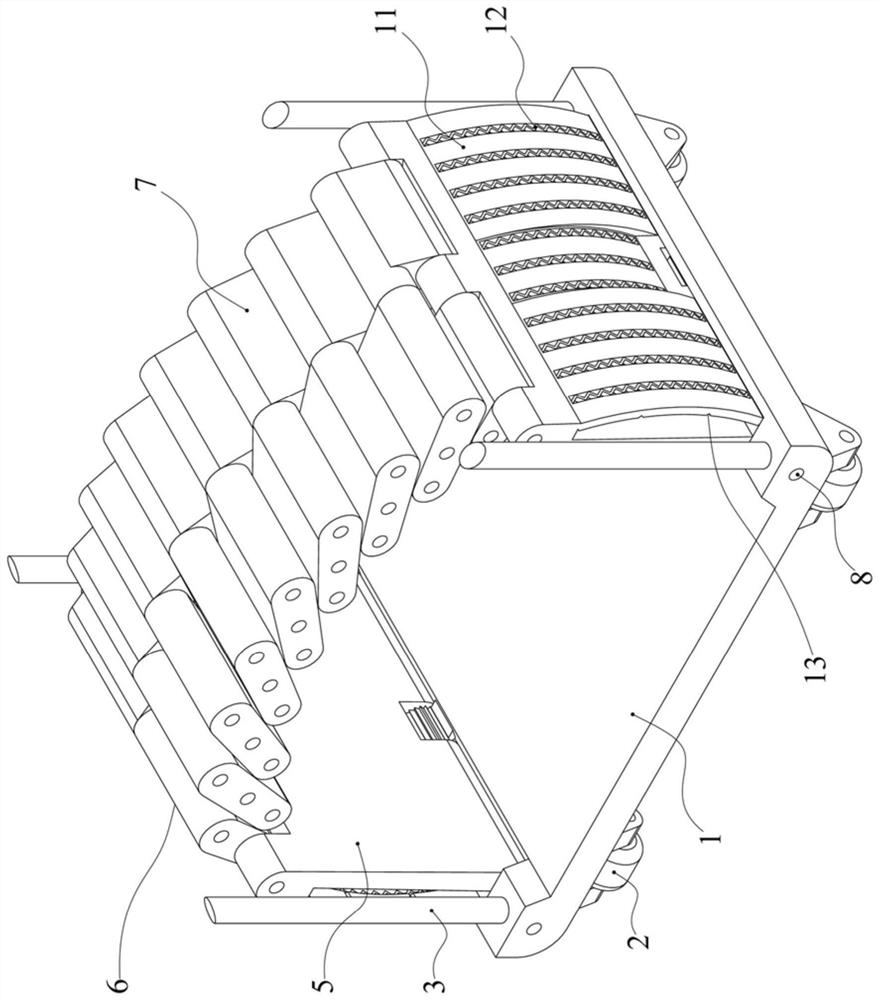

[0022] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Depend on Figure 1 to Figure 6 Given, the present invention comprises a base plate 1, a plurality of wheels 2 traveling forward and backward are arranged below the base plate 1, and a top cover 4 is connected through a pillar 3 above the base plate 1; Directional symmetry setting (i.e. attached figure 1 , 4 The left and right symmetry in the two vertical support plates 5, the direction of the plate surface of the support plate 5 is consistent with the direction of travel of the wheel 2 (that is, the attached figure 1 , 4 The front and rear directions in the middle), the lower end of the support plate 5 and the base plate 1 are elastically hinged with the wheel 2 traveling direction as the axis, and the upper ends of the two support plates 5 are hinged through the X-shaped telescopic frame 6.

[0024] Under no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com