Preparation method of disperse dye ordinary-pressure low-temperature easily-dyeable superfine fibers

A technology of disperse dyes and ultrafine fibers, which is applied in the direction of chemical post-treatment of single-component copolyester rayon and synthetic polymer rayon, which can solve the problems of application limitations, difficulty in dyeing dark colors, etc., and improve water absorption Performance, improved dyeability, easy access effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing disperse dyes at normal pressure and low temperature and easy to dye superfine fibers, comprising the following preparation methods:

[0037] (1) Preparation of low-temperature easy-to-dye modified copolyester:

[0038] (1.1) Mix terephthalic acid, ethylene glycol and a titanium catalyst for esterification reaction at 225-235°C and a pressure of 0.1-0.3Mpa for 1.5-2.5h, and control the esterification rate above 85% to obtain an esterified product; the titanium catalyst is added The amount is 5ppm based on the proportion of Ti atomic mass to the theoretical polyester production amount;

[0039] (1.2) Add diol and polyester polyol to the esterified product, then react at 255-265°C and 50-150pa pressure for 40-60min to carry out precondensation, and react at 265-275°C and 100-120pa pressure for 1.5- 2.5h to carry out final polycondensation, discharge, and prepare low-temperature easy-to-dye modified copolyester; the alkyd ratio of the ethylene glyco...

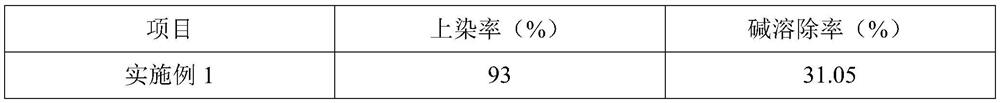

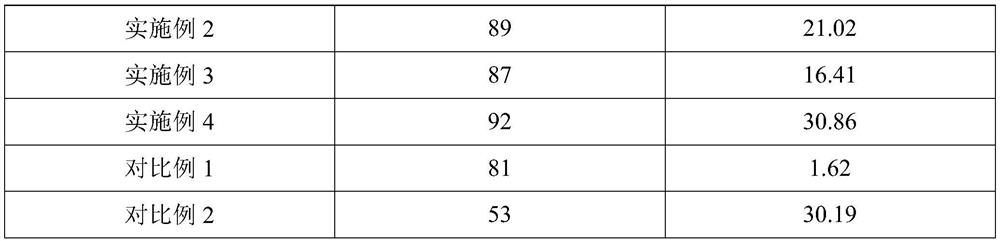

Embodiment 1

[0049] A method for preparing disperse dyes at normal pressure and low temperature and easy to dye superfine fibers, comprising the following preparation methods:

[0050] (1) Preparation of low-temperature easy-to-dye modified copolyester:

[0051] (1.1) Mix terephthalic acid, ethylene glycol, and a commercial titanium-based polyester catalyst at 230°C and 0.2Mpa pressure for an esterification reaction for 2 hours, and control the esterification rate to more than 85% to obtain an esterified product; the addition of the titanium catalyst is The proportion of Ti atomic mass to the theoretical polyester production is 5ppm;

[0052] (1.2) Add 4wt% of 2-methyl-1,3-propanediol and 2wt% polyethylene adipate (PEA-2000) of low-temperature easy-to-dye modified copolyester in the esterified product, followed by React at 260°C and 100pa pressure for 50 minutes for pre-condensation, react at 270°C and 110pa pressure for 2 hours for final polycondensation, and discharge the material to pr...

Embodiment 2

[0056] A method for preparing disperse dyes at normal pressure and low temperature and easy to dye superfine fibers, comprising the following preparation methods:

[0057] (1) Preparation of low-temperature easy-to-dye modified copolyester:

[0058] (1.1) Mix terephthalic acid, ethylene glycol, and a commercial titanium-based polyester catalyst at 235°C and 0.3Mpa for an esterification reaction for 1.5 hours, and control the esterification rate to more than 85% to obtain an esterified product; the amount of titanium catalyst added The theoretical polyester production amount based on Ti atomic mass is 5ppm;

[0059] (1.2) Add 4wt% of 2-methyl-1,3-propanediol and 2wt% polyethylene adipate (PEA-2000) of low-temperature easy-to-dye modified copolyester in the esterified product, followed by React at 265°C and 150pa pressure for 40min for pre-condensation, react at 275°C and 120pa for 1.5h for final polycondensation, and discharge to prepare low-temperature dyeable modified copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com