Oxygen inhalation bottle cap gasket and preparation method and application thereof

A technology of cover gasket and oxygen absorber, which is applied in the field of food packaging and food storage, can solve the problems of low loss of nutrients, high cost of factory lines, incomplete killing of microorganisms, etc., and achieve good compatibility and oxygen absorption capacity Excellent, excellent oxygen absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

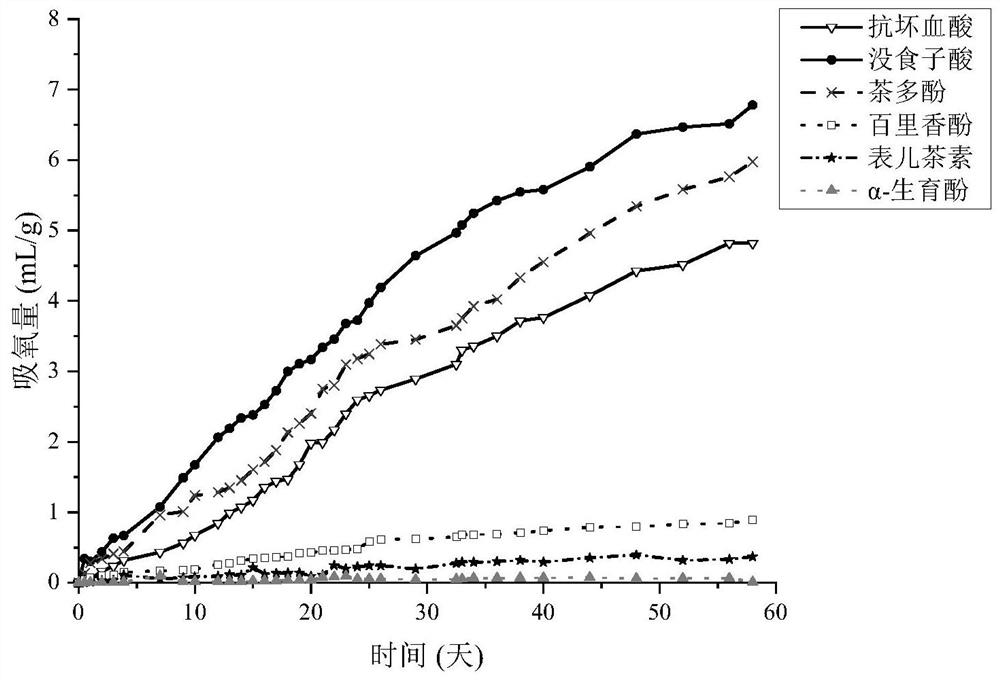

[0070] Embodiment 1, the preparation of oxygen-absorbing agent and condition screening thereof

[0071] 1. Preparation of different types of oxygen-absorbing main agents

[0072] 1) Weigh the same mass of ascorbic acid, gallic acid, tea polyphenols, thymol, epicatechin and α-tocopherol in glass bottles.

[0073] 2. Preparation of oxygen absorbing main agent solution

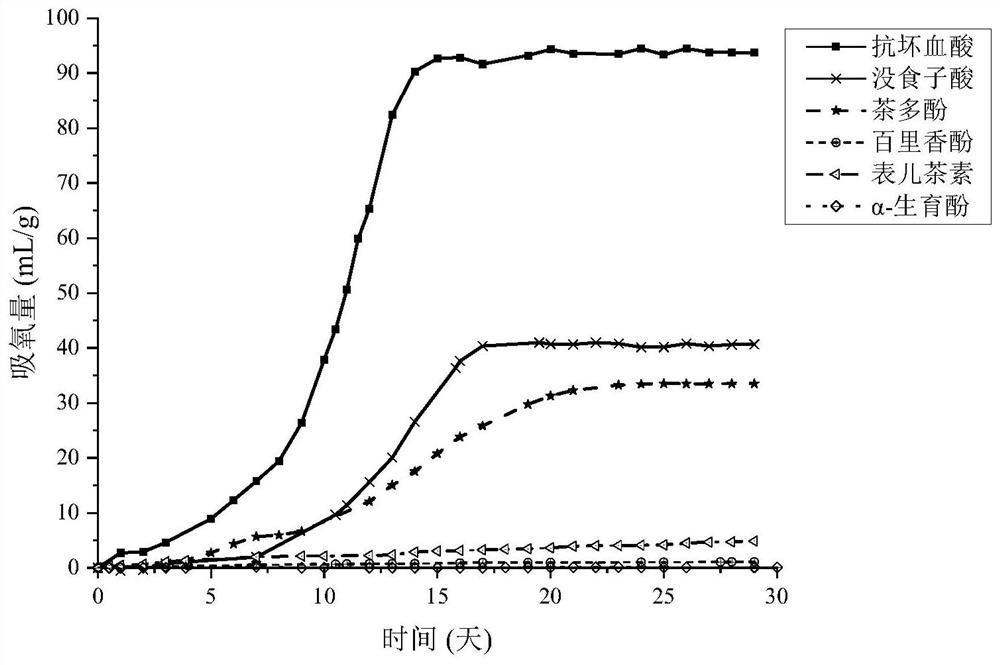

[0074] 1) Oxygen absorbent with sodium carbonate added: Weigh the same mass of ascorbic acid, gallic acid, tea polyphenols, thymol, epicatechin and α-tocopherol in glass bottles, and add the same mass of Sodium carbonate at a ratio of 1 / 2 and shake well on a spiral shaker.

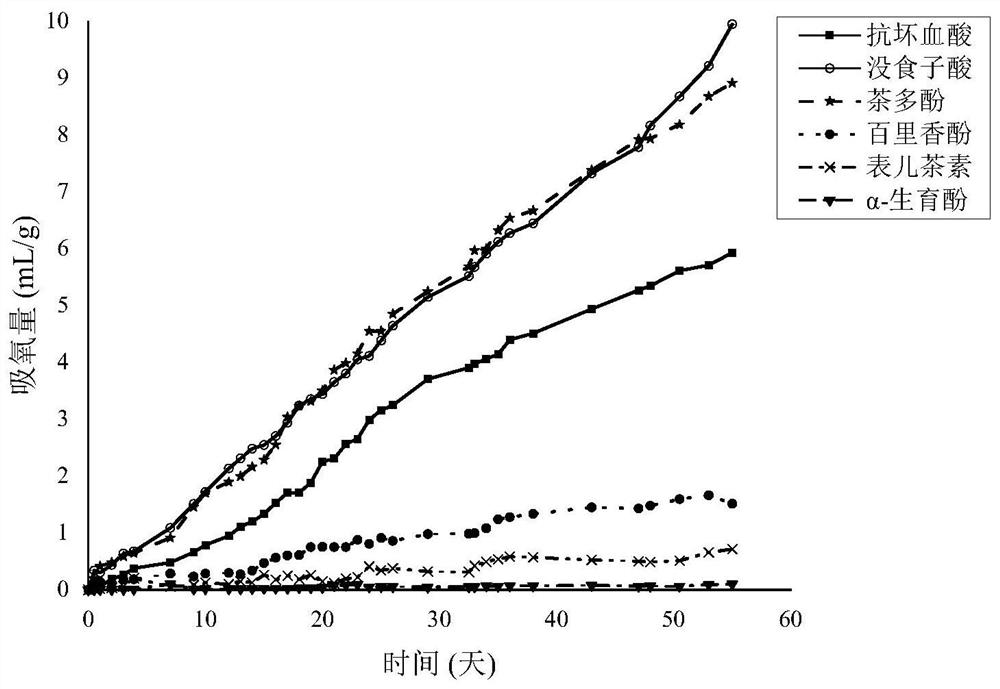

[0075] 2) Oxygen absorber with citric acid added: Weigh the same mass of ascorbic acid, gallic acid, tea polyphenols, thymol, epicatechin and α-tocopherol in glass bottles, and add the same mass of ascorbic acid into the bottles citric acid at a ratio of 1 / 2 and shake well on a spiral shaker.

[0076] 3. Preparation of Oxygen Absorber Con...

Embodiment 2

[0088] Embodiment 2, oxygen absorbing bottle cap gasket and its preparation

[0089] 1. Preparation of Oxygen Inhalation Bottle Cap Gasket

[0090] According to the optimal ratio of activated carbon to sodium ascorbate in Example 1 of the present invention of 3:5 (or the mass ratio of ascorbic acid to sodium carbonate and activated carbon is 10:5:6), the oxygen absorbing bottle cap gasket was prepared. Different concentration gradients of sodium ascorbate-activated carbon in low-density polyethylene (LDPE) are set, which are 0%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45% There are 10 groups in total. Gaskets for oxygen-absorbing bottle caps were prepared through melt blending, extrusion granulation, film casting, and tablet cutting. The specific process parameters are:

[0091] 1) Melt blending: adding oxygen absorbers of different concentrations into the LDPE pellet matrix for mixing;

[0092] 2) Extrusion granulation: Extrude and granulate the melt-blended material. Pel...

Embodiment 3

[0103] Example 3, the impact of oxygen absorbing bottle cap gasket packaging on the quality of orange juice during storage

[0104] In this implementation case, the commercially available 100% concentrated reduced orange juice is used as the raw material for illustration.

[0105] 1. Orange Juice Sample Preparation

[0106] Take 100% orange juice from the production line of the production plant on the same day, and fill it into sterilized glass bottles on the ultra-clean workbench. The volume of the glass bottle is 300mL. Three kinds of headspace volumes were set, and the ratios of headspace volume to juice volume were: 1 / 7 (low-volume headspace group), 1 / 5 (medium-volume headspace group) and 1 / 3 (high-volume headspace group). ). Six groups of treatments were set up: low-volume headspace group (H 1 ), middle-volume headspace group (H 2 ), high-volume headspace group (H 3 ), low headspace - oxygen-absorbing packaging (H 1 -OS), middle headspace-oxygen package (H 2 -OS), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com