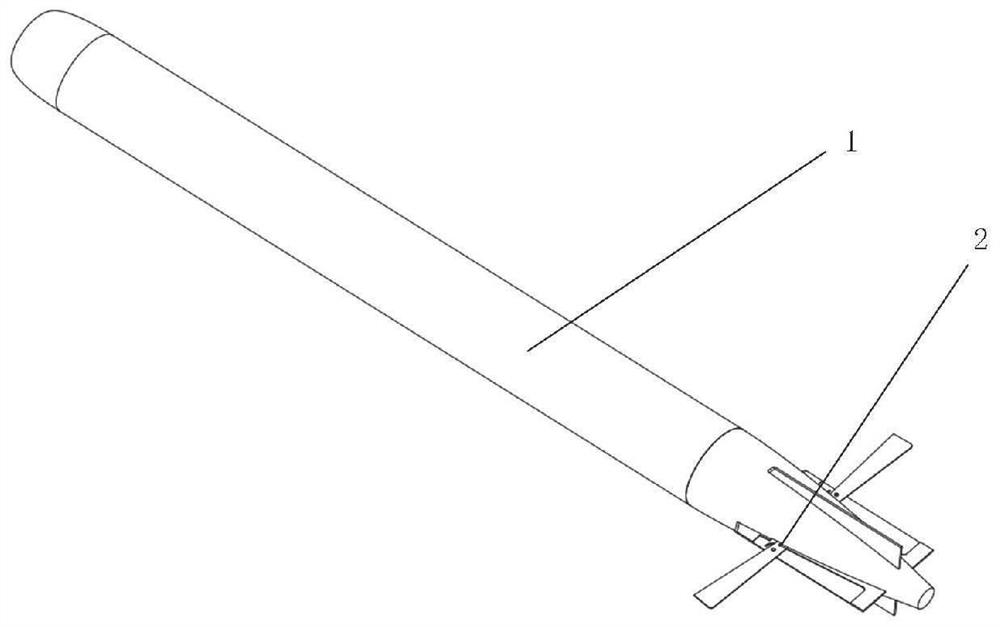

forward ejection stability augmentation device for horizontal fin of rotary AUV (Autonomous Underwater Vehicle)

A stability-increasing device and a horizontal technology, applied to equipment for increasing stability of ships, transportation and packaging, underwater operation equipment, etc. To avoid problems such as dynamic instability, achieve the effects of light weight, increased elongation, and small motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

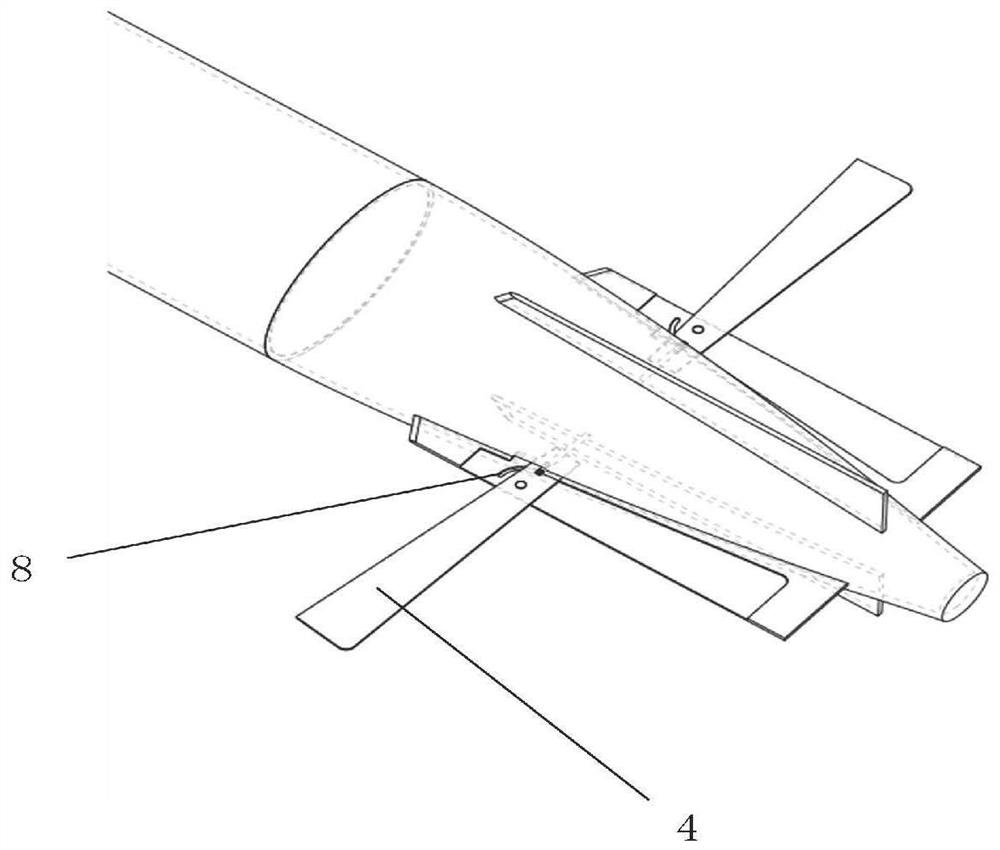

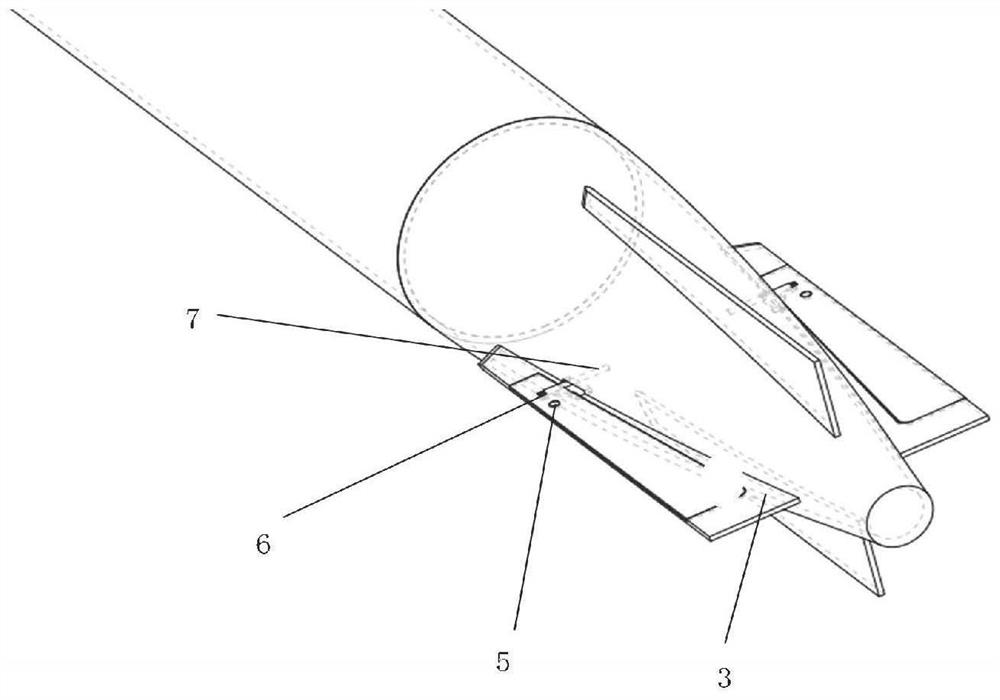

[0045] Such as Figure 5 As shown in the schematic diagram of the non-pop-up state of the forward pop-up stabilization device of the horizontal fin, when the working state does not require high handling stability, the triangular movable fin plate 4 is in the position groove of the horizontal fin plate of the fixed cross-shaped fin rudder mechanism 3, through the hydraulic pressure Bar 7, limit slideway 8 and other control mechanism guarantee that triangular movable fin plate 4 is fixed. When there is a high stability requirement for the gyratory AUV1, such as Figure 6 As shown in the schematic diagram of the pop-up state of the horizontal fin forward pop-up stabilization device, the hydraulic pump starts to work, drives the hydraulic rod 7 to move, and pushes the triangular movable fin plate 4 to rotate along the limit slideway 8. When the movable fin plate 4 rotates to the designated working position , the hydraulic pump stops working, and the hydraulic rod 7 stops moving. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com