Dryer with fluff removing function for cotton and wool cloth

A technology for dryers and wool cloth, applied in the field of textile production, can solve the problems of poor quality cotton wool, low efficiency, and affecting cotton cloth processing, and achieve the effect of avoiding fluff flying and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

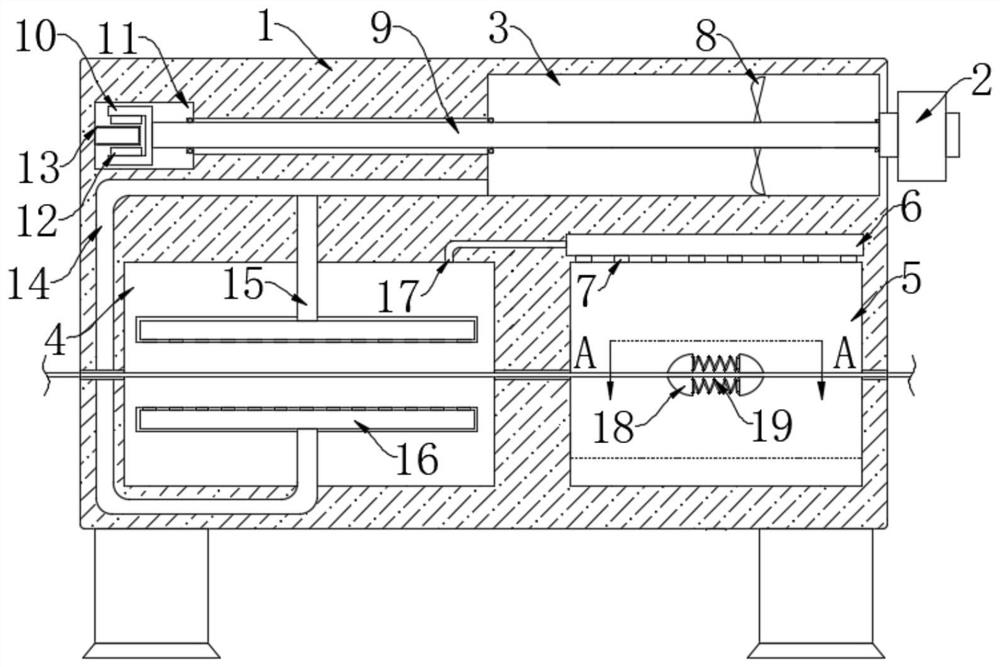

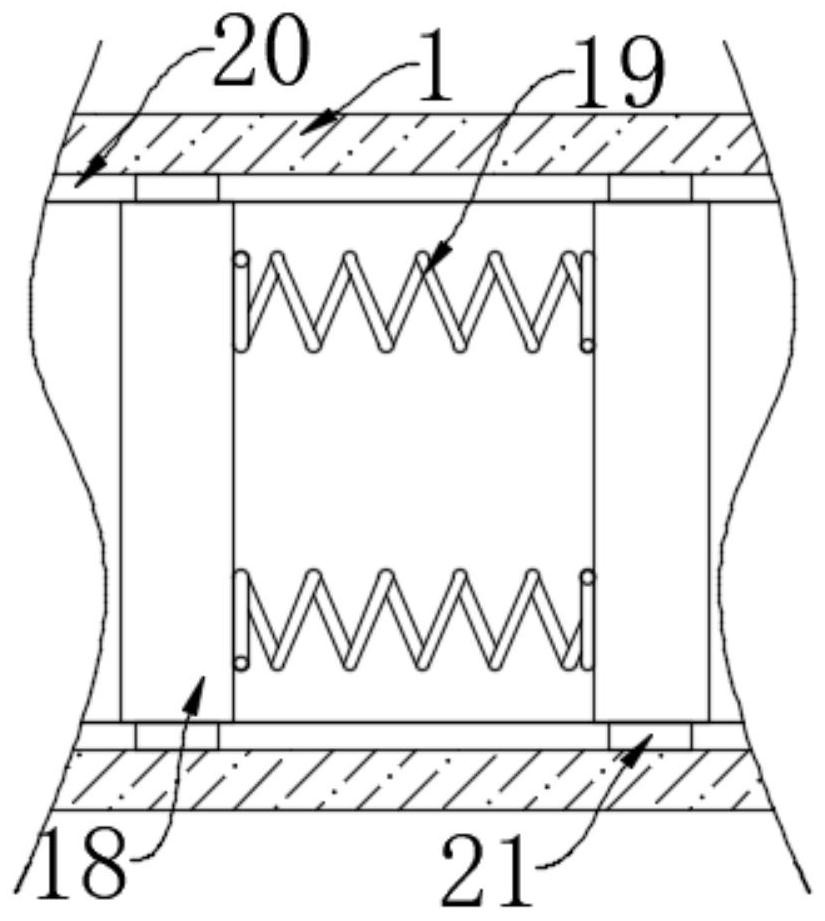

[0022] refer to Figure 1-2 , a dryer for cotton and wool fabrics with the function of delinting, comprising a housing 1, in which a drying chamber 4 and a delinting chamber 5 are sequentially arranged from left to right, and a suction chamber is arranged in the housing 1 3. The suction chamber 3 is located above the delint chamber 5, and the housing 1 is provided with a power generation chamber 11, which is located on the left side of the suction chamber 3;

[0023] Drying mechanism, the drying mechanism includes a hot air blower 2 arranged at the right end of the housing 1, the air outlet of the hot air blower 2 is connected to the air suction cavity 3, and two hollow plates 16 are symmetrically arranged in the drying chamber 4, and two hollow plates 16 are arranged symmetrically. The opposite sides of the plates 16 are provided with a plurality of air holes, and the air holes on the two hollow plates 16 are relatively arranged to facilitate the drying of both sides of the c...

Embodiment 2

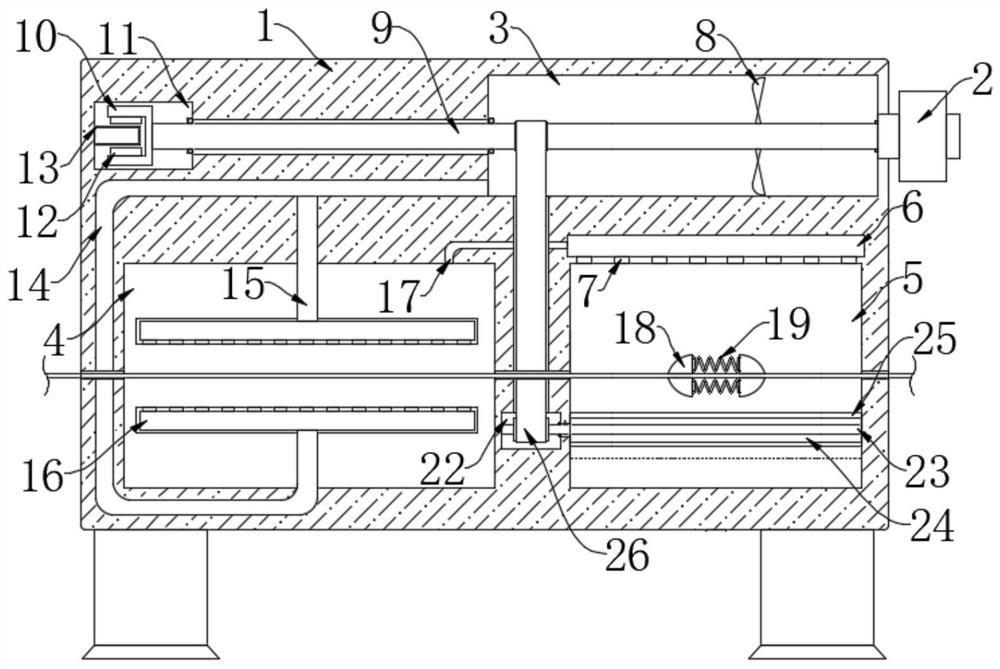

[0030] refer to image 3The difference between this embodiment and Embodiment 1 is that a transmission chamber 22 is provided in the housing 1, and a second rotating rod 23 is horizontally provided in the transmission chamber 22, and the two ends of the second rotating rod 23 are connected to The inner walls on both sides are rotationally connected, and the transmission structure 26 is connected between the first rotating rod 9 and the second rotating rod 23. The transmission structure 26 includes two transmission wheels installed on the first rotating rod 9 and the second rotating rod 23 respectively. The two transmission wheels are connected by a transmission belt, and the right end of the second rotating rod 23 extends into the fleece removal chamber 5 and is rotationally connected with the right inner wall of the fleece removal chamber 5, and the second rotation rod 23 is located in the fleece removal chamber 5 Part of the outer wall is fixedly connected with a silk layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com