PE water supply pipe production line

A production line and water supply pipe technology, applied in metal processing, etc., can solve the problems of high manpower consumption and the inability of the pipe winding frame 3 to work continuously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

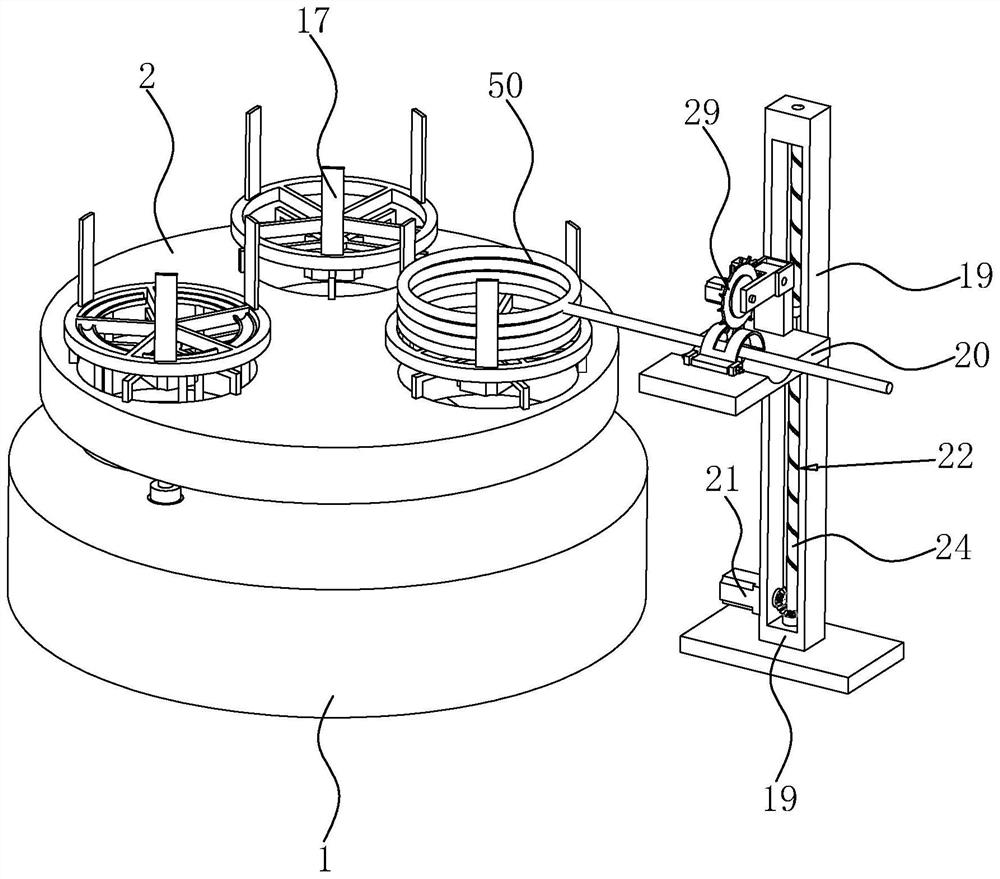

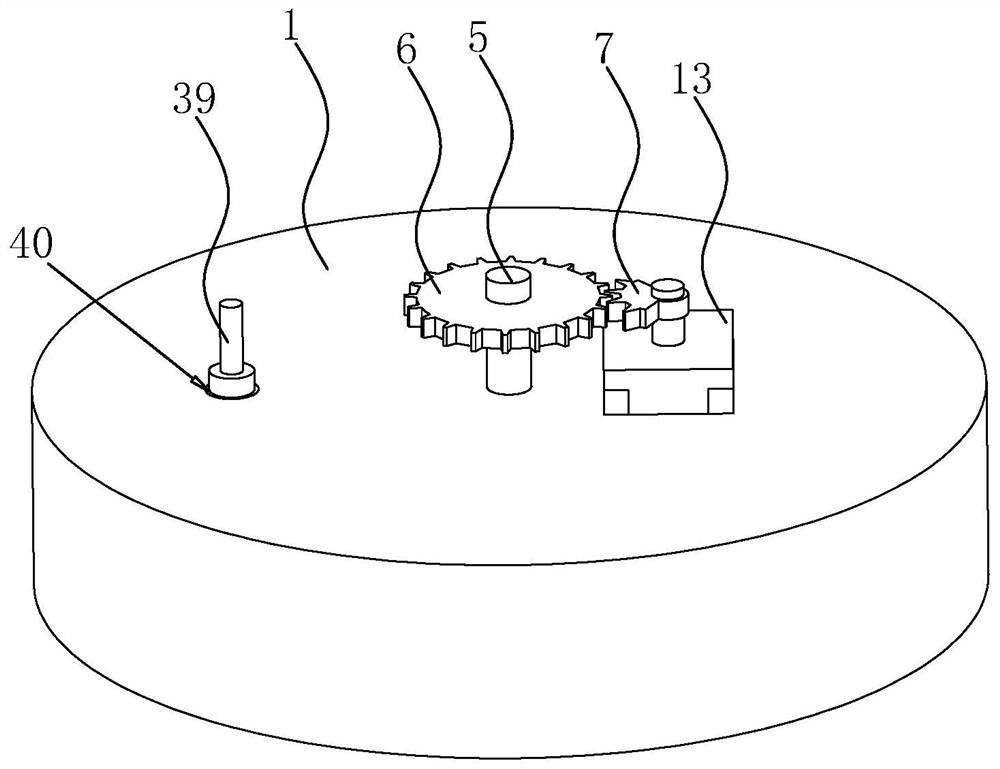

[0038] The following is attached Figure 1-7 The application is described in further detail.

[0039] The embodiment of the application discloses a PE water supply pipe production line.

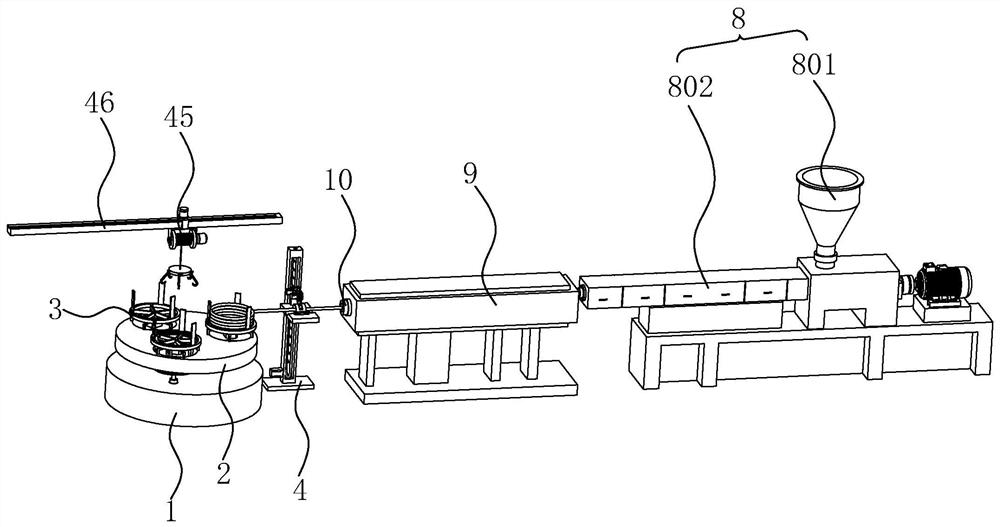

[0040] refer to figure 1 , a PE water supply pipe production line, the main product of the PE water supply pipe production line in this application is a water supply pipe for transporting water resources. PE is a kind of polyethylene plastic. PE pipes are widely used in the fields of building water supply and urban water supply due to its excellent and unique properties. When preparing PE pipes in the production line, it needs to go through operations such as injection molding, cooling and setting, and discharge cutting. The plastic extruder in the process of injection molding is a twin-screw extruder 8, and the twin-screw extruder includes a feed hopper 801 and a body 802. Put the plastic material into the feed hopper 801 , mix the plastic material evenly under the rotation of the screw ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap