Pressure balancing mechanism

A technology of balancing mechanism and pressure, which is applied in the field of pressure balancing mechanism, and can solve problems such as pollution, waste of plastic polymer materials that cannot be recycled, and impact on production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

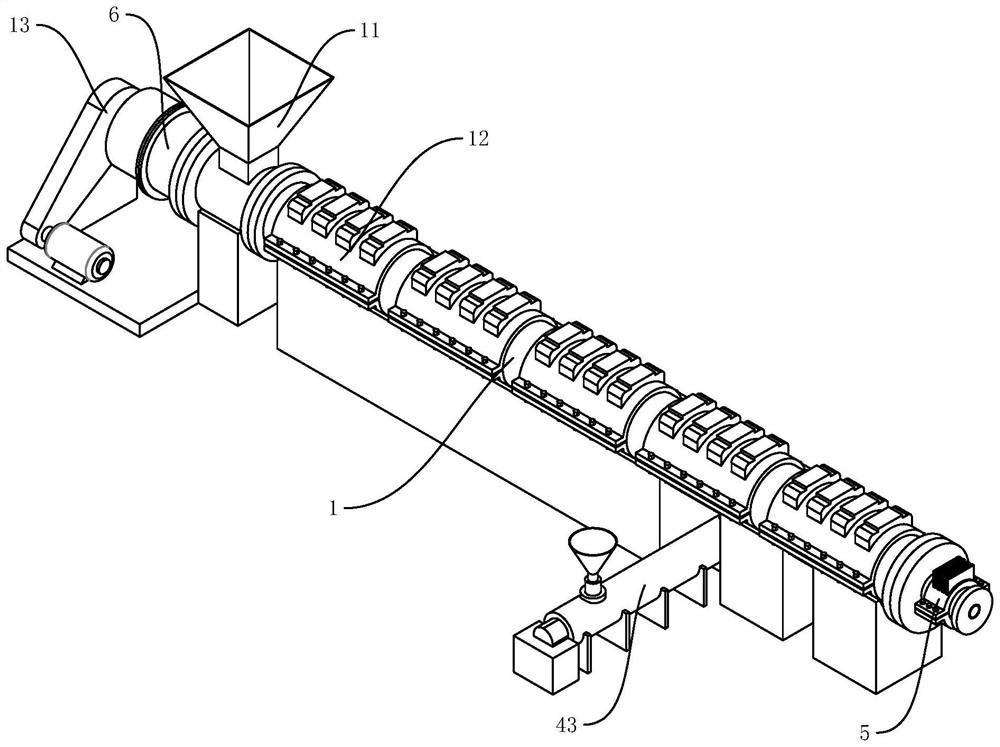

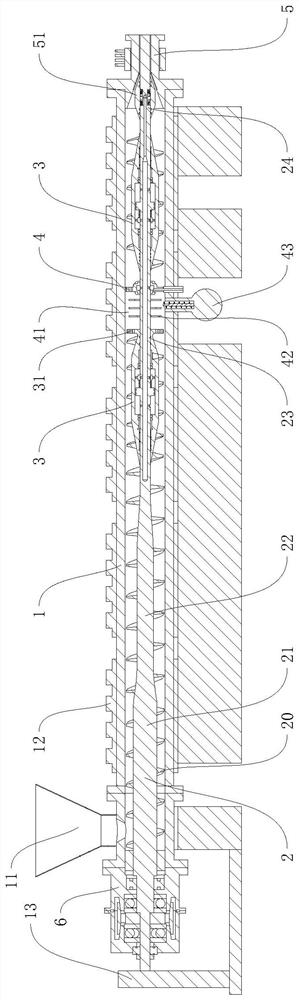

[0030] This embodiment discloses an extruder, referring to figure 1 and figure 2 As shown, it includes a cylinder body 1 and a screw rod 2. The cylinder body 1 is divided into a feed end and a discharge end. A feed hopper 11 is installed on the feed end for raw materials to enter. , for the material to flow out; a heating device 12 is arranged on the outer periphery of the cylinder 1 to heat the material sheet in the cylinder 1; the screw 2 is connected to the inside of the cylinder 1 through the support device 6, and the outer periphery of the screw 2 is fixed with The screw blade 20 is driven to rotate by the driving mechanism 13 , and the screw blade 20 extrudes the heated and melted raw material from the discharge head 5 during the rotation. A plurality of pressure detection sensors are installed at various positions in the cylinder body 1 to monitor the material pressure parts in the cylinder body 1 .

[0031] In the extruder, the screw 2 includes a first rod segment 2...

Embodiment 2

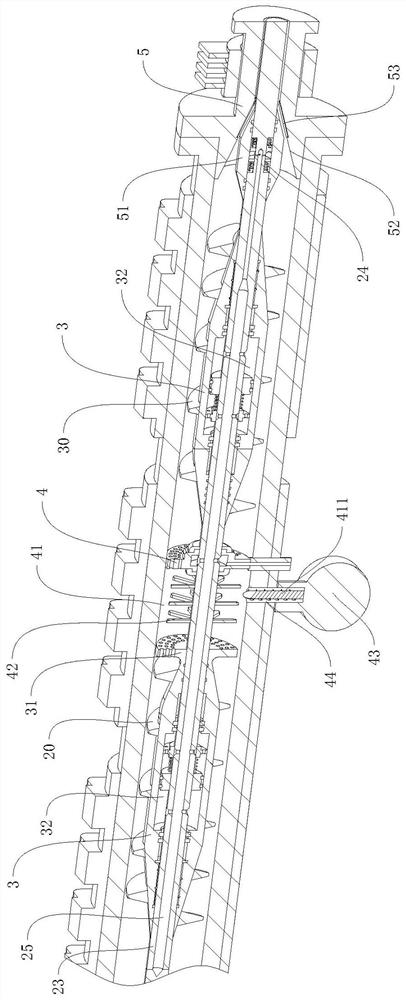

[0033] This embodiment discloses a pressure balance mechanism, refer to image 3 , 4 , 5, this mechanism can be installed in the plastic extruder as in embodiment 1, and mainly includes two stable sliding sleeves, and the two pressure stabilizing sliding sleeves 3 are sleeved on the outside of the screw rod 2, and can be rotated relative to the screw rod 2. To move, the internal structures of the two pressure stabilizing sliding sleeves 3 are similar, and are relatively upside-down structures.

[0034]The outer wall of the voltage stabilizing sliding sleeve 3 is cylindrical in the middle, and the two ends are gradually tapered. The inner wall of the voltage stabilizing sliding sleeve 3 is adapted to the third rod end. A main pressure stabilizing chamber 32 is formed between the ring groove and the screw rod 2; the ring groove 33 is sealed at both ends of the pressure stabilizing main chamber 32, and a seal 2 331 is installed between the sealing ring groove 33 and the screw ro...

Embodiment 3

[0042] This embodiment discloses a pressure balance mechanism. On the basis of the second embodiment, in order to further increase the effect of the pressure fit, the axial movement of the pressure stabilizing sliding sleeve 3 is further guided and restricted. On the inner wall of the voltage stabilizing sliding sleeve 3, a guide slip ring groove 34 is also provided, and a guide slide mechanism is set between the inner wall of the guide slip ring groove 34 and the outer wall of the screw rod 2 at the corresponding position, and the guide slide mechanism can guide the pressure stabilizing slide sleeve 3 and the axial and radial movement of the screw 2, and guide when the pressure-stabilizing sliding sleeve 3 moves axially; and a seal three 343 is set between the two ends of the guide sliding sleeve and the screw 2, through the sealing Part three 343 seals the space of the guide slip ring groove 34, so that the space inside the guide slip ring groove 34 can be kept sealed during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com