Energy-saving mobile charging station

A charging station and mobile technology, applied in the field of energy-saving mobile charging stations, can solve the problems of resource waste and unavailability, and achieve the effect of saving electric energy and avoiding resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

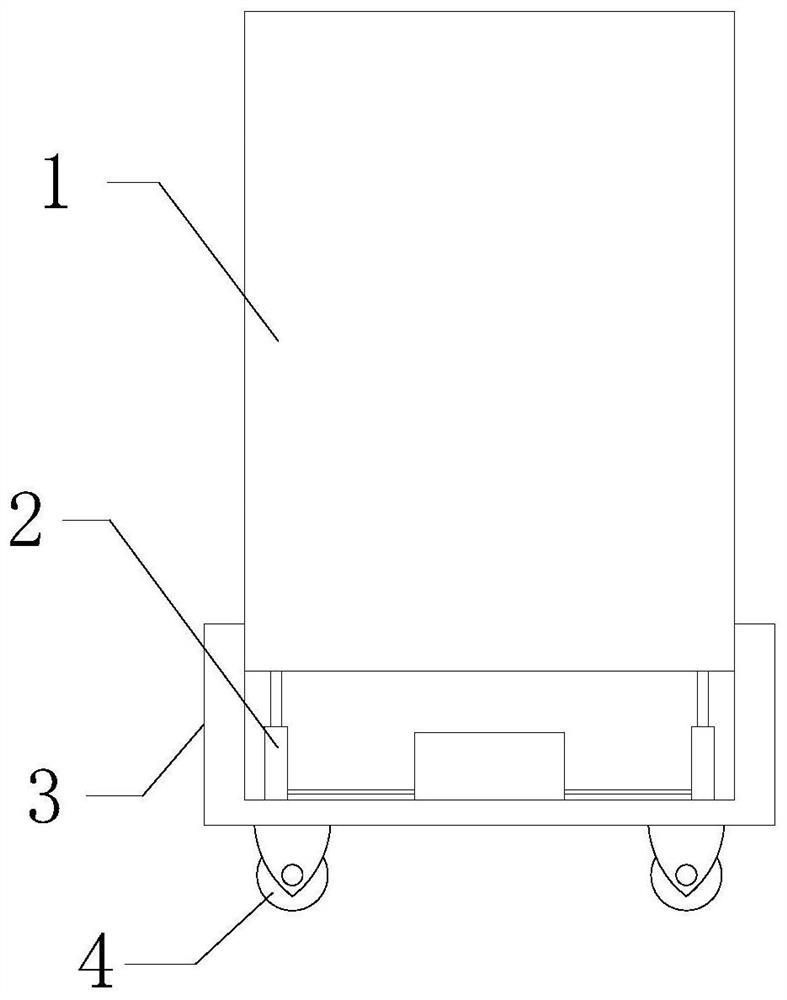

[0024] see Figure 1-Figure 4 , an energy-saving mobile charging station, comprising a charging station body 1, a base 3 and a universal wheel 4, the charging station body 1 is located on the base 3, and the universal wheel 4 is rotatably connected to the bottom of the base 3; including an energy-saving mechanism 2. The energy saving mechanism 2 is located between the base 3 and the charging station body 1 .

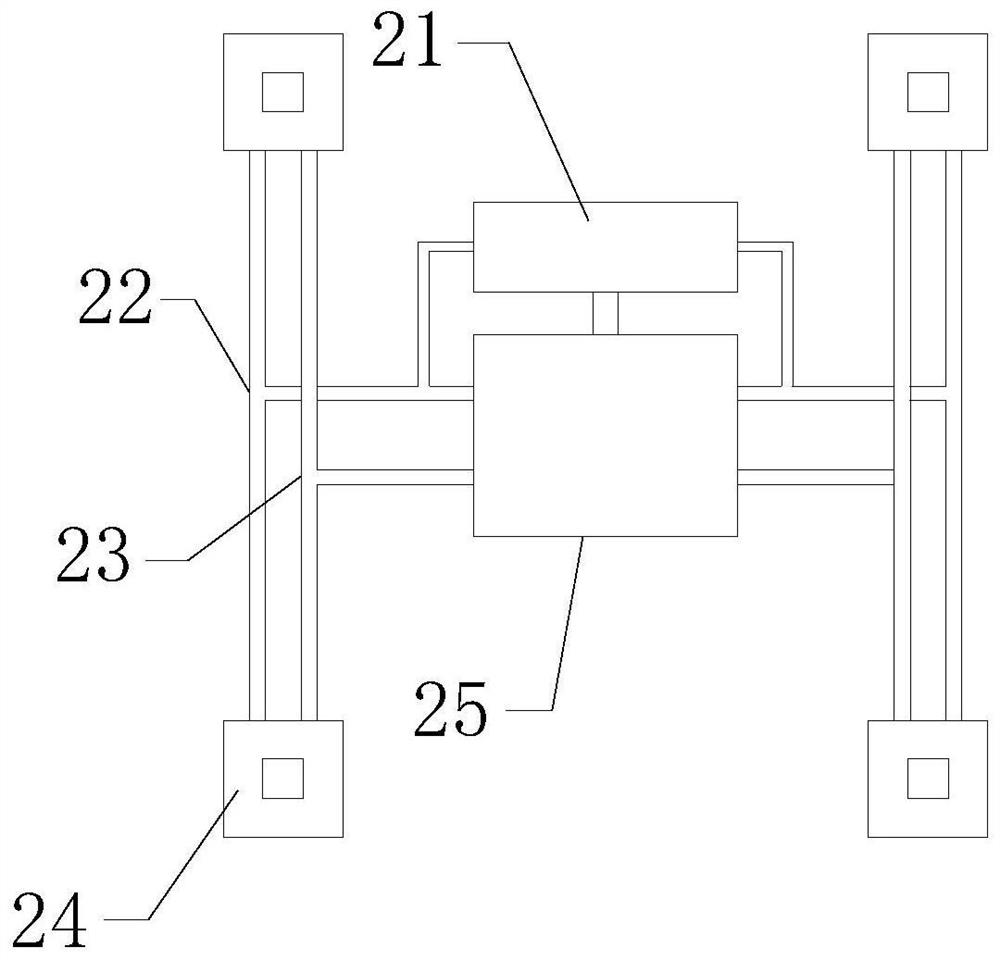

[0025] As an improvement of the above solution, the energy-saving mechanism 2 includes a power cylinder 24 and a generator 21 , the power cylinder 24 is arranged between the base 3 and the charging station body 1 , and the fixing part of the power cylinder 24 is fixed on the base 3 , and the telescopic part of the power cylinder 24 is fixedly connected with the charging station body 1, the oil inlet 254 of the generator 21 is connected with the oil outlet of the power cylinder 24 through the oil inlet pipeline 23, and the oil outlet of the generator 21 is connected It i...

Embodiment 2

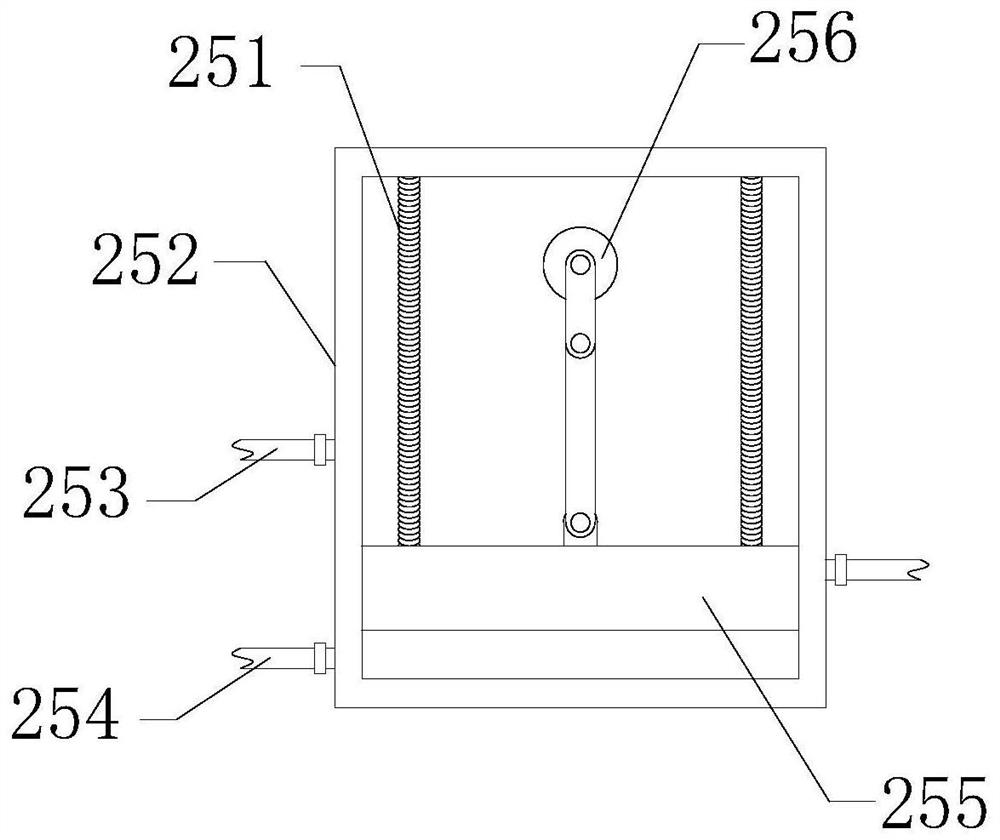

[0029] see image 3 , as an improvement of the above scheme, the energy-saving mechanism 2 also includes a voltage-stabilizing assembly 25, the voltage-stabilizing assembly 25 includes a voltage-stabilizing chamber 252, a piston plate 255 and a spring 21, and the bottom of the voltage-stabilizing chamber 252 is connected with an oil inlet Port 254, the pressure chamber 252 is connected with an oil outlet, and the oil outlet is opened later than the oil inlet 254, and the oil inlet 254 is connected with the oil inlet pipeline 23, and the oil outlet is connected with the oil inlet of the generator 21. The port 254 is connected, the piston plate 255 is slidably connected to the inner wall of the surge chamber 252, and the surge chamber 252 is divided into two mutually sealed cavities, and the piston plate 255 is connected to the surge chamber 252 through the spring 21. .

[0030] As an improvement of the above solution, both the oil inlet 254 and the oil outlet are provided with...

Embodiment 3

[0033] see Figure 4 , as an improvement of the above scheme, the voltage stabilization component 25 includes an auxiliary voltage stabilization structure 256, and the auxiliary voltage stabilization structure 256 includes a rotating shaft 2561, a torsion spring 2564, a first connecting rod 2562 and a second connecting rod 2563. The rotating shaft 2561 is rotatably connected inside the pressure-stabilizing chamber 252, the torsion spring 2564 is sleeved outside the rotating shaft 2561, and is fixed inside the pressure-stabilizing chamber 252, one end of the first connecting rod 2562 is fixedly connected with the rotating shaft 2561, and the first connecting rod 2562 is fixedly connected to the rotating shaft 2561. One end of the second connecting rod 2563 is rotatably connected with the other end of the first connecting rod 2562 , and the second connecting rod 2563 is rotatably connected to the piston plate 255 .

[0034] Working process: when the piston plate 255 moves upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com