Battery changing battery box charging method system

A charging method and charging system technology, which are applied in the field of car charging pile charging, can solve the problem of inability to extract battery pack voltage information, etc., and achieve the effect of facilitating lightweight design, efficient charging and battery swapping operations, and optimizing resource allocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

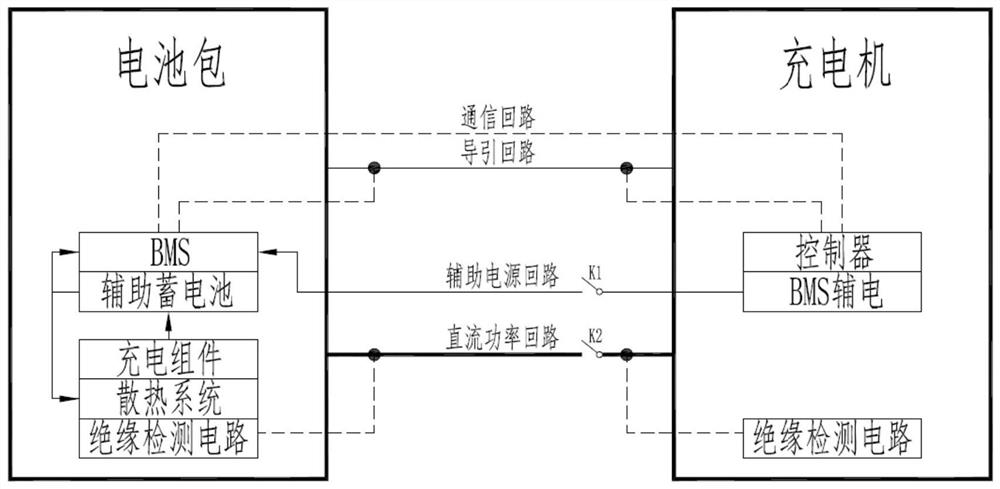

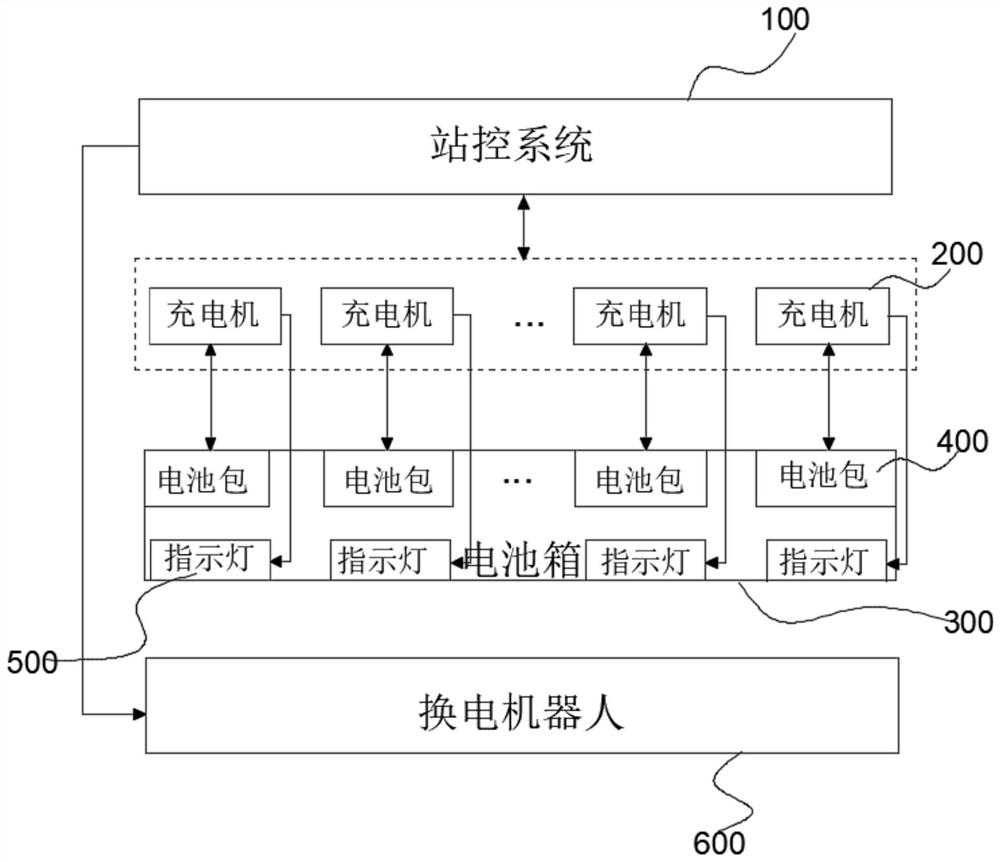

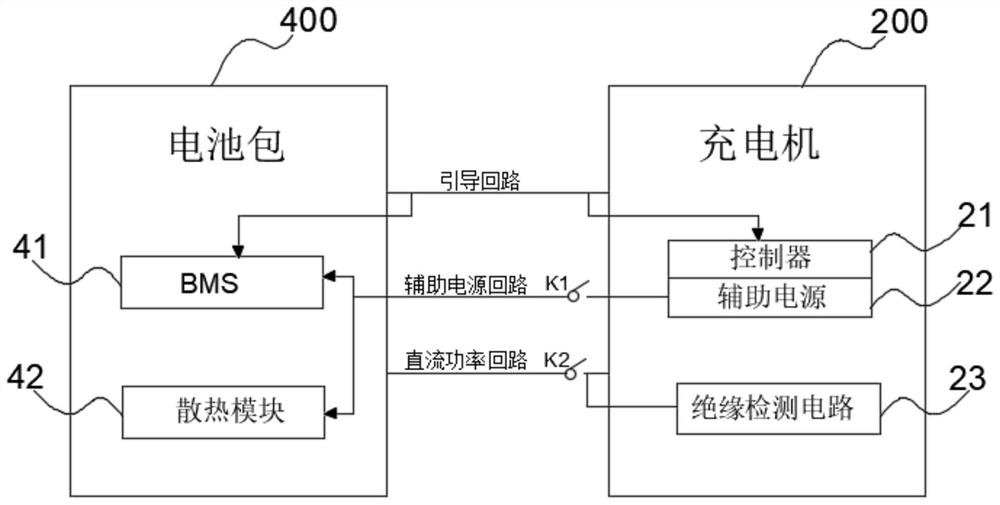

[0039] See attached Figure 2-3 As shown, a battery swapping battery box 300 charging system of the present invention includes a station control system 100 , several chargers 200 , a battery box 300 and a battery swapping robot 600 . The battery box 300 is provided with a charging position corresponding to the charger 200, the battery pack 400 is stored in the charging position, the battery exchange robot 600 is connected to the station control system 100 by communication, and the battery exchange robot 600 is used for The battery pack 400 is inserted into or removed from the battery case 300 . The charger 200 charges the battery pack 400 and communicates with the battery pack 400 , and the charger 200 and the battery pack 400 conduct guidance, energy transmission and information interaction. The station control system 100 is communicatively connected with the charger 200, the station control system 100 receives the feedback information from the charger 200 and sends an opera...

Embodiment 2

[0047] See attached Figure 4-5 , a method for charging battery pack 300 in the present invention, comprising the following steps,

[0048] Step 1. The station control system 100 gives instructions to the battery swapping robot 600, and the battery swapping robot 600 inserts the battery pack 400 that has lost power into the vacant charging compartment of the battery box 300.

[0049] Step 2. The station control system 100 issues an instruction to start charging to the charger 200. The charger 200 controls the auxiliary electrical circuit to conduct, and supplies power to the BMS 41 and the cooling module 42 in the battery pack 400 through the auxiliary power supply 22 in the charger 200.

[0050] Step 3. The charger 200 and the BMS 41 respectively detect whether the guiding circuit connecting the two is conducting, and if it is normal, execute step 4; otherwise, execute step 5.

[0051] Step 4. The charger 200 starts communication with the BMS 41, starts charging, and collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com