Swing butt-joint oblique pressing type garbage compression transfer station

A technology of garbage compression and garbage compressor, which is used in trash cans, garbage conveying, garbage collection, etc., can solve the problems of inability to separate garbage cans, low loading efficiency and volumetric efficiency of garbage cans, and large space requirements, and achieves high space occupation. The effect of less, high loading utilization rate, improving utilization rate and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

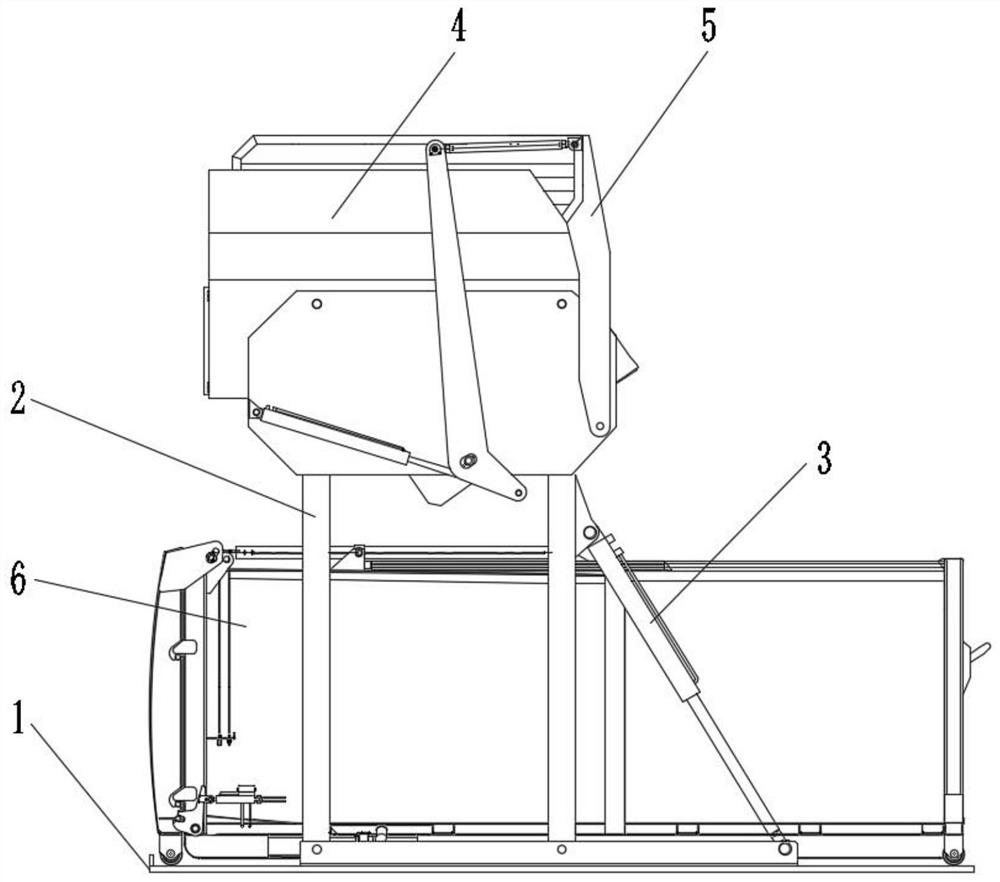

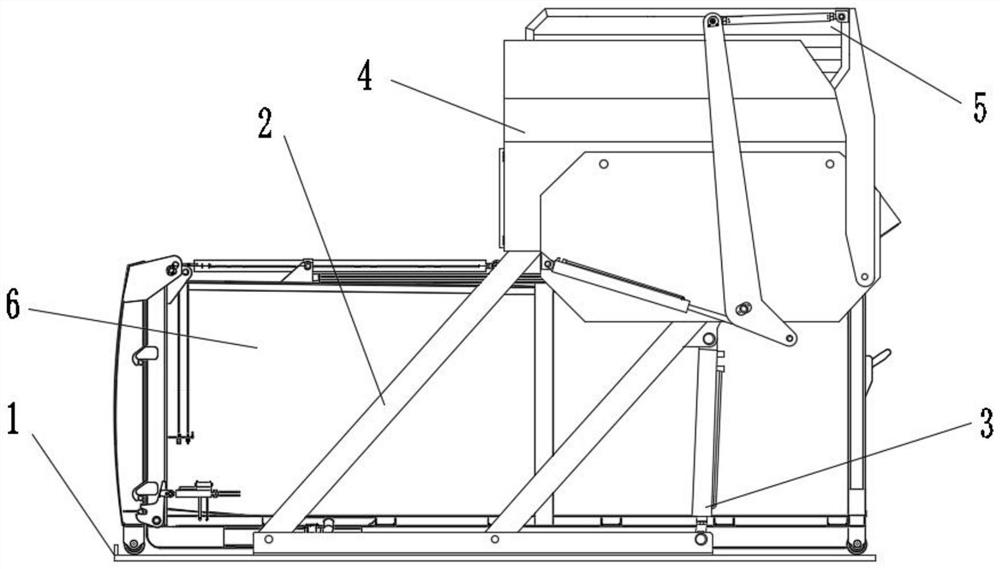

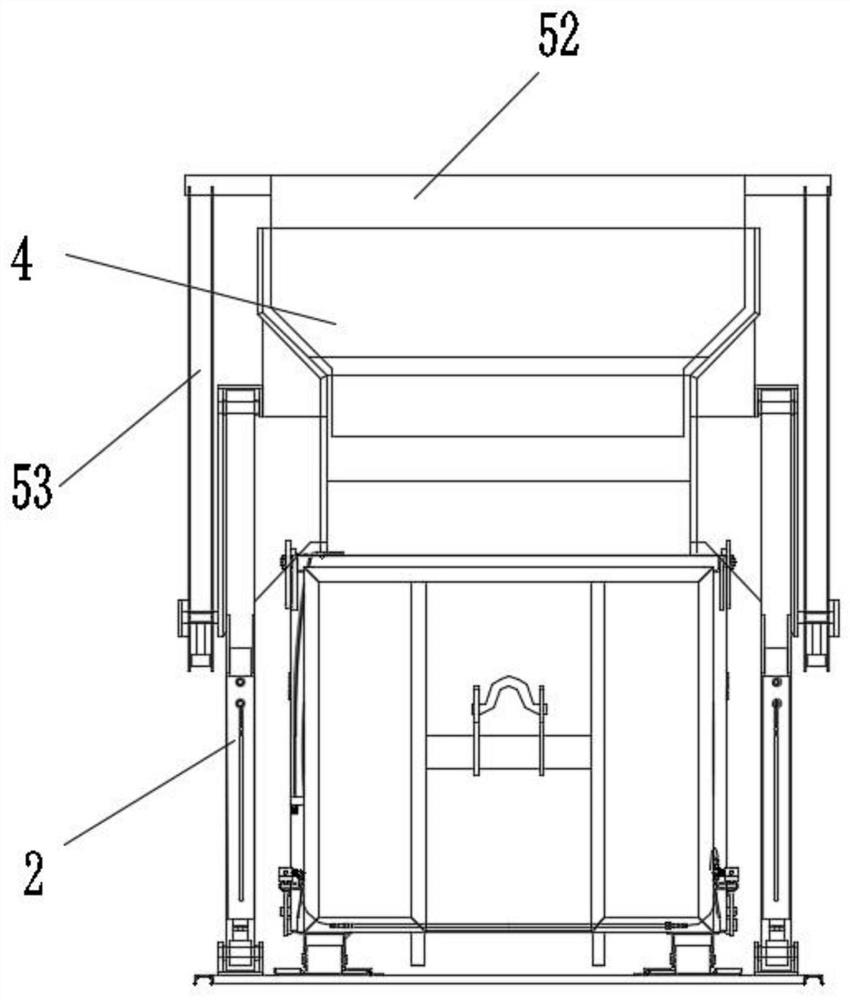

[0034] Such as figure 1 , 2 As shown in and 3, the swing docking baroclinic rubbish compression transfer station includes a guide rail frame 1 installed on the ground, a dustbin 2 and two swing arm bases, and the two swing arm bases are located on both sides of the dustbin 6, and the swing arm bases are respectively Two swing arms 2 are connected, and a garbage compressor 4 is connected above the two swing arms 2. The base of the swing arm, the swing arm 2 and the garbage compressor 4 form a four-bar linkage mechanism. There is a swing arm oil cylinder 3, and the swing arm oil cylinder 3 drives the swing arm 2 to make the garbage compressor 4 rotate as a whole, and realizes the docking and separation of the garbage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com