Rapid cooling mold of oil-filled glass bottle and implementation method thereof

A rapid cooling, glass bottle technology, used in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of fragile glass bottles, uneven temperature, different cooling rates of glass liquid, etc., to simplify preheating and cooling. The operation and structure are complete and reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] In order to better demonstrate the implementation process of the rapid cooling mold of the oil-filled glass bottle, this embodiment now proposes a method for implementing the rapid cooling mold of the oil-filled glass bottle, including the following steps:

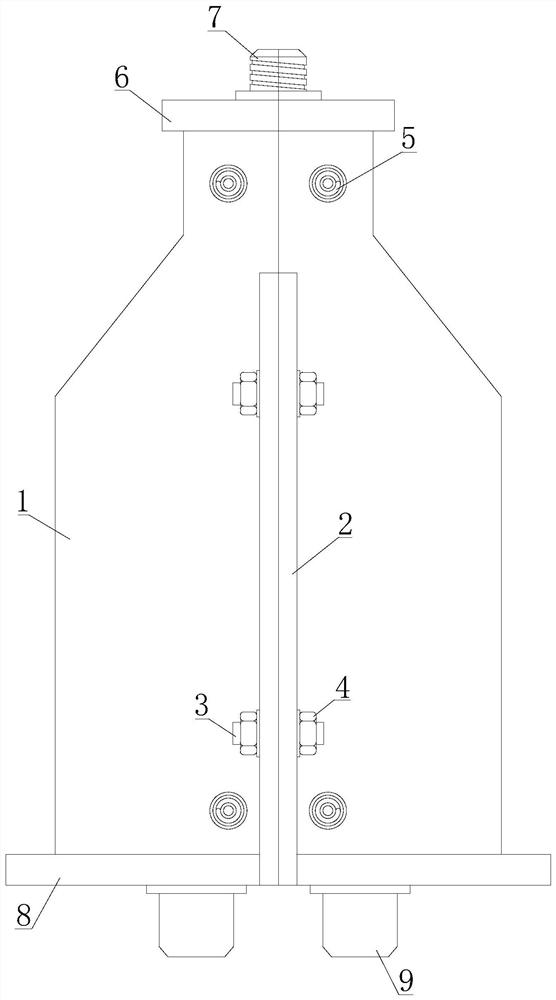

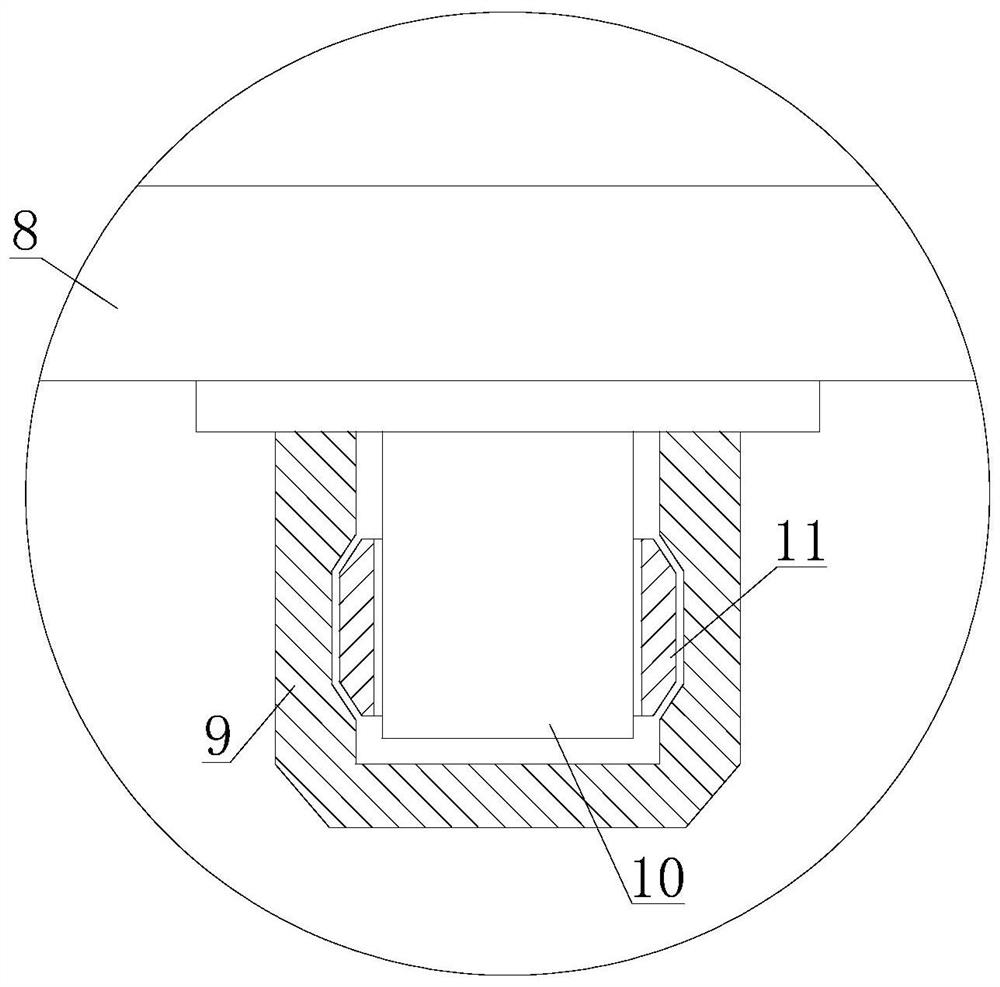

[0032] Step 1: Combine the mold shell 1, and use the through screw 3 and the through nut 4 to close the two sides of the mold shell 1, install the injection component 7 on the upper side of the limit top plate 6, and use the sealing outer cover 9 and the sealing gasket 11 Seal the discharge port 10 at the bottom;

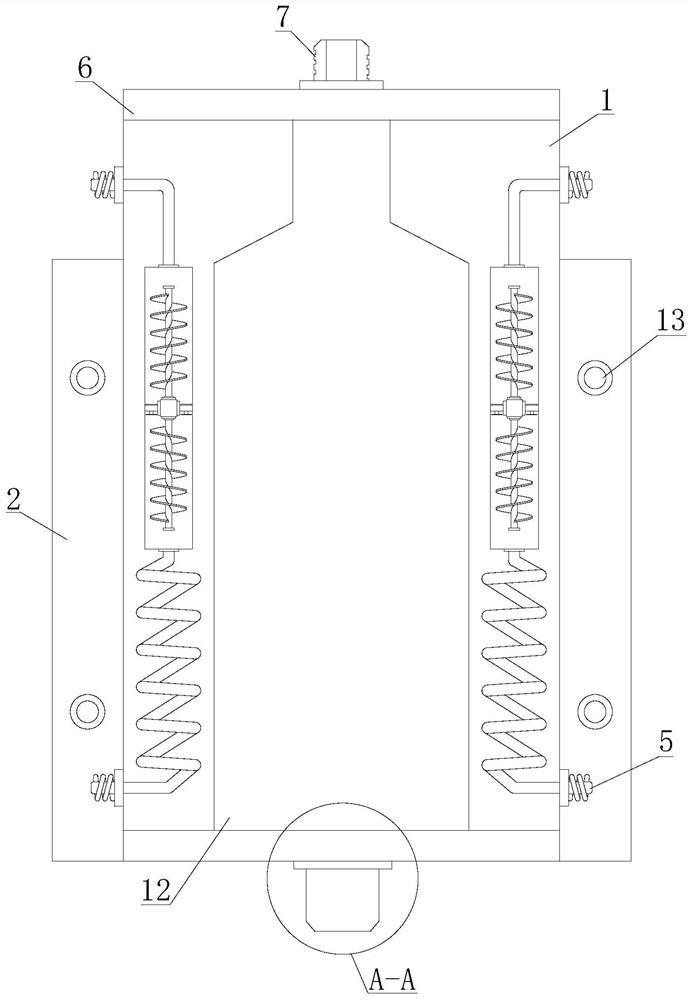

[0033] Step 2: Connect the hot water pipes to the cooling water interface 52 in the rapid cooling assembly 5 respectively, feed hot water, and turn on the snap-in motor 58 to carry out stirring and conveying of the hot water, and the temperature of the hot water is used to control the temperature of the mold shell 1. preheating;

[0034] Step 3: Inject glass liquid into the inner cavity 12 of the mold sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com