Silicon carbide wafer, crystal ingot and preparation method thereof

A silicon carbide single crystal and silicon carbide technology, which is applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve the complex influencing factors, incomplete silicon carbide single crystal, and silicon carbide single crystal growth quality conditions. Advanced problems, to achieve the effect of simple control method, less quantity and uniform resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

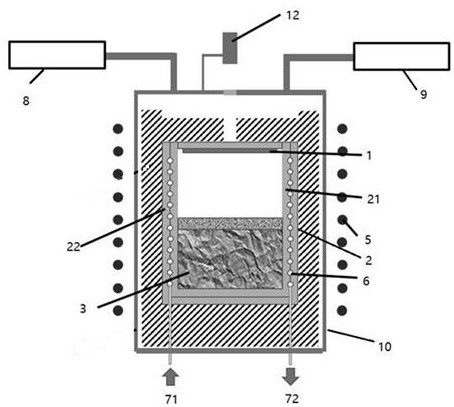

[0074] refer to figure 1 , the sidewall of the crucible is provided with a nitrogen channel 6, the nitrogen channel 6 is arranged in the sidewall of the crucible and extends around the inner cavity of the crucible, and the inner sidewall of the nitrogen channel is less dense than the outer sidewall of the nitrogen channel.

[0075] As an embodiment, the crucible 2 includes a lining 21 and an outer shell 22, the sidewall of the crucible forms a nitrogen gas channel 6, the nitrogen gas channel 6 is a spiral channel, the spiral channel extends spirally around the inner cavity of the crucible along the axial direction of the crucible, and the nitrogen gas channel is at the bottom of the crucible. and the top at least once. For example, the nitrogen gas channel extends from the gas inlet 71 at the bottom of the crucible to the top of the crucible and then extends to the bottom of the crucible to form the gas outlet 72 .

[0076] Specifically, the inner liner 21 and the outer shell...

Embodiment 2

[0079] refer to figure 1 , according to an embodiment of the present application, a method for preparing a silicon carbide single crystal ingot using the crucible of Example 1 includes the following steps:

[0080] 1) Preparation of silicon carbide single crystal ingot:

[0081] The crucible with the nitrogen gas channel of Example 1 is provided, the nitrogen gas channel is arranged in the sidewall of the crucible and extends around the inner cavity of the crucible, and the inner sidewall of the nitrogen gas channel is less dense than the outer sidewall of the nitrogen gas channel;

[0082] The silicon carbide seed crystal 1 is placed on the top of the crucible 2 and the silicon carbide raw material 3 is placed on the bottom of the crucible 2, the crucible 2 is assembled with a heat preservation structure and placed in the crystal growth furnace 10, and the induction coil 5 is used for heating;

[0083] The temperature controller 12 controls the temperature of the crystal gro...

Embodiment 3

[0091] Example 3 Preparation of Silicon Carbide Single Crystal Ingot 1#

[0092] The preparation method of silicon carbide single crystal ingot 1# comprises the following steps:

[0093] The crucible with the nitrogen gas channel of Example 1 is provided, the nitrogen gas channel is arranged in the side wall of the crucible and extends around the inner cavity of the crucible, and the inner wall density of the nitrogen gas channel is 1.70 g / cm 3 , the density of the shell is 1.90g / cm 3 ;

[0094] The silicon carbide seed crystal is placed on the top of the crucible and the silicon carbide powder is placed on the bottom of the crucible, and the heat preservation structure is assembled outside the crucible and sealed in the crystal growth furnace;

[0095] Control the temperature and pressure of the crystal growth furnace and the flow of argon gas into the crystal growth furnace to clean and remove impurities in the crystal growth furnace;

[0096] Heating stage: adjust the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com