Textile wrinkle removing device

A textile and storage box technology, applied in the direction of textiles and papermaking, transportation and packaging, fabric surface trimming, etc., can solve the problems of textile damage, continuous work, affecting product quality, etc., to protect safety, reduce impact force, avoid The effect of vibration transmission down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

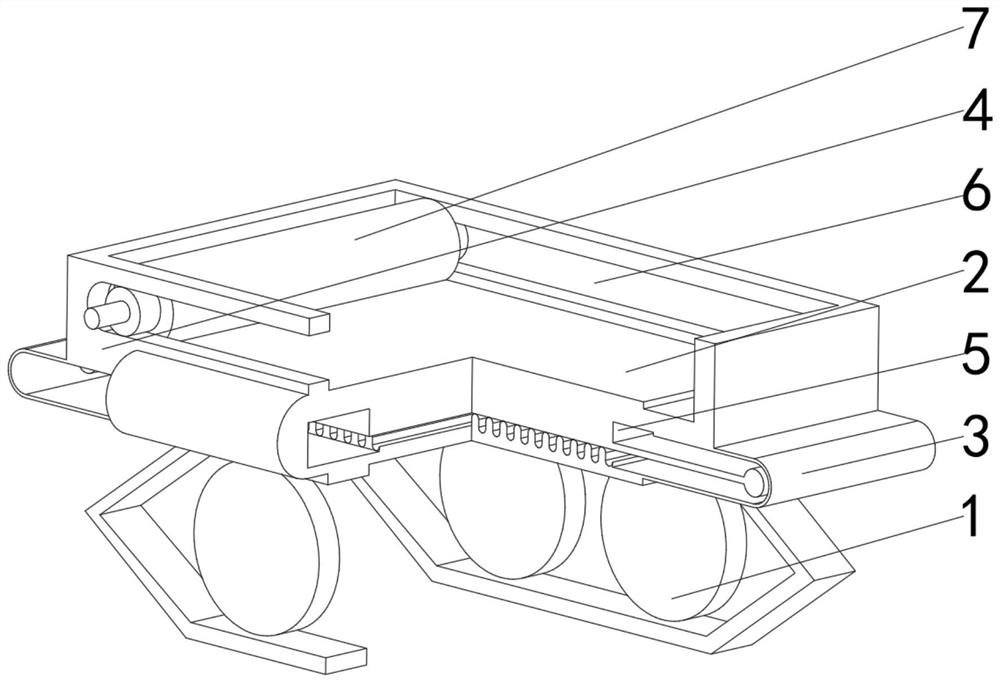

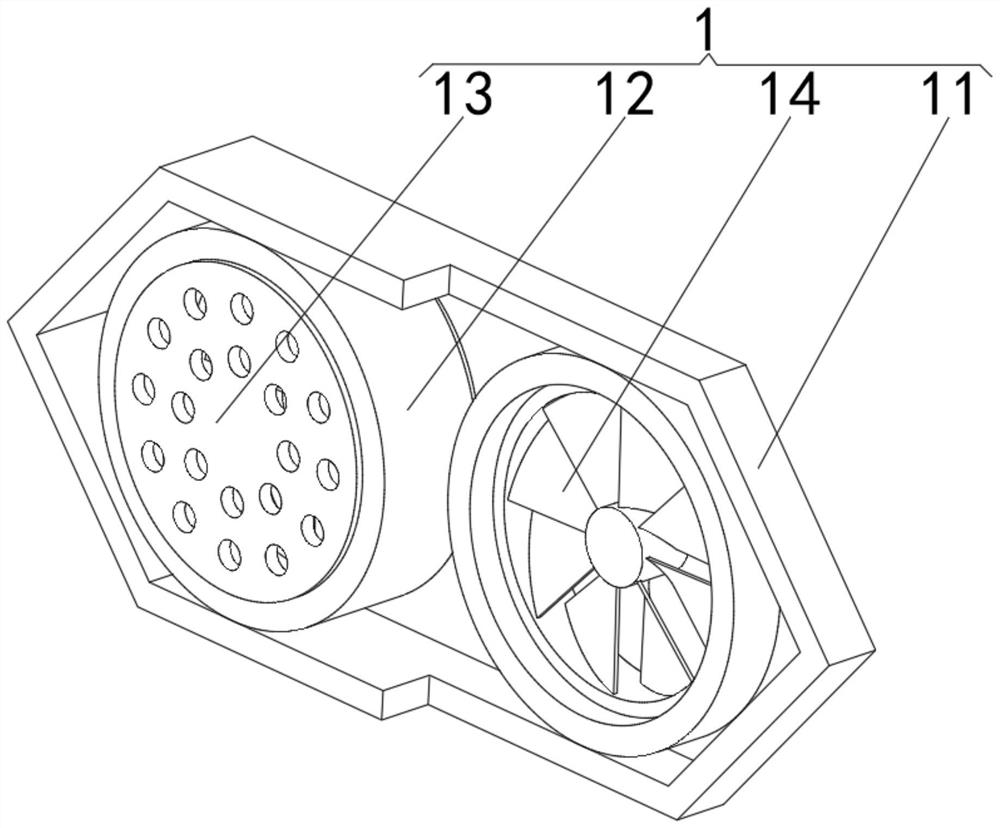

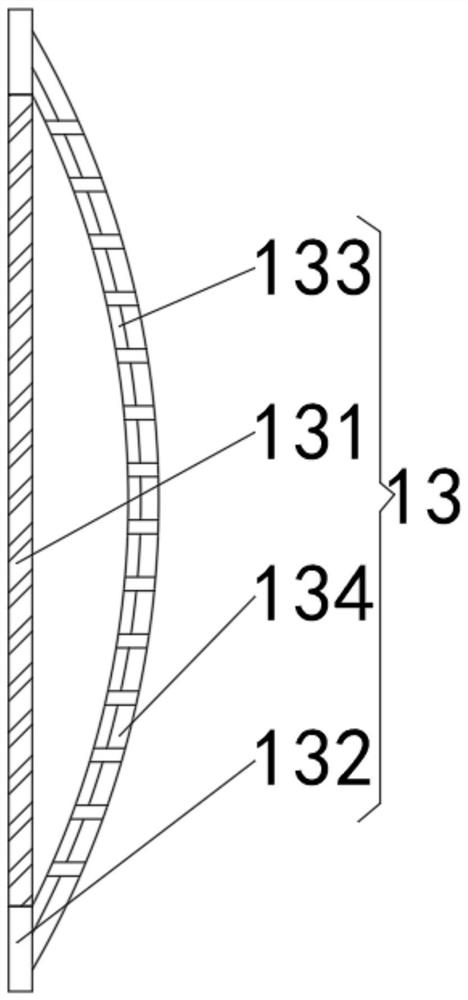

[0034] see Figure 1-6 , The present invention provides a technical solution: a textile wrinkle removal device, comprising a support mechanism 1, the top of the support mechanism 1 is fixedly connected with an annular ironing board 2, and the bottom of the inner surface of the annular ironing board 2 is fixedly connected with an energy supply mechanism 3, The top of the inner surface of the annular ironing board 2 is fixedly connected with a placing box 4, and the middle position of the bottom of the placing box 4 is fixedly connected with a knocking mechanism 5. The annular ironing board 2 runs through the placing box 4 and extends to the front and back of the placing box 4. The placing box 4. The front and the back are located above the annular ironing board 2 with a track groove 6. The inner surface of the track groove 6 is fixedly connected with a leveling roller 7. The bottom of the placing box 4 is located on both sides of the knocking mechanism 5 and is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com