Fabricated waterproof glass daylighting roof

A lighting roof, prefabricated technology, used in skylights/domes, roofs, buildings, etc., can solve the problems of water leakage at the connection between the lighting glass and the frame, water accumulation in the house, time-consuming and laborious, etc. The effect of convenient disassembly, maintenance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Attached below Figure 1-4 Specific embodiments of the present invention will be described in further detail.

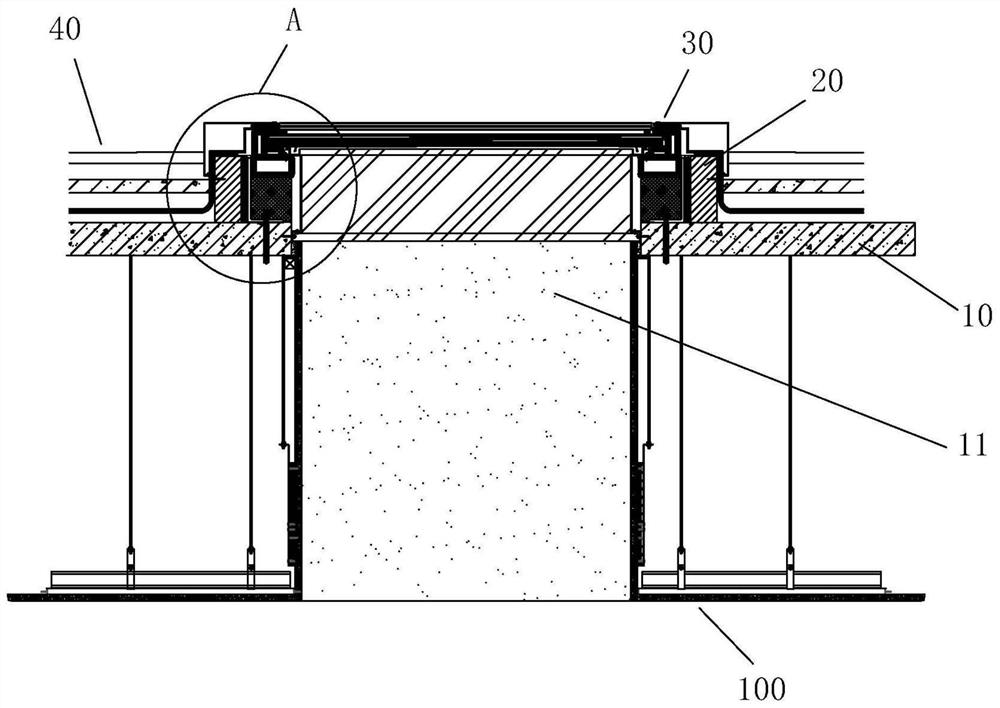

[0028] An assembled waterproof glass daylighting roof of the present invention comprises: a structural floor 10 and a daylighting square hole 11 set on the structure floor 10, and concrete partition blocks are poured on the edges of the structure floor 10 around the daylighting square hole 11 20. A daylighting roof device 30 is provided on the structural floor 10 inside the concrete partition block 20, and a floor decorative layer structure 40 is provided on the structural floor 10 outside the concrete partition block 20;

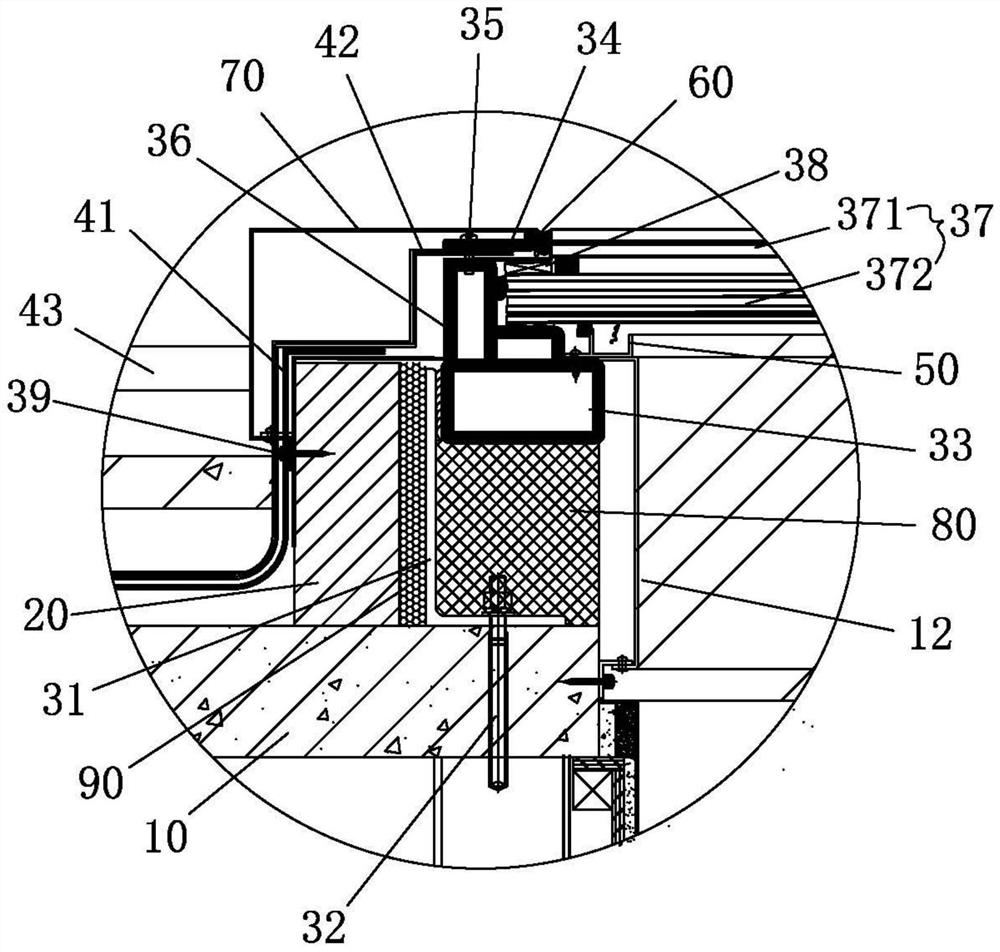

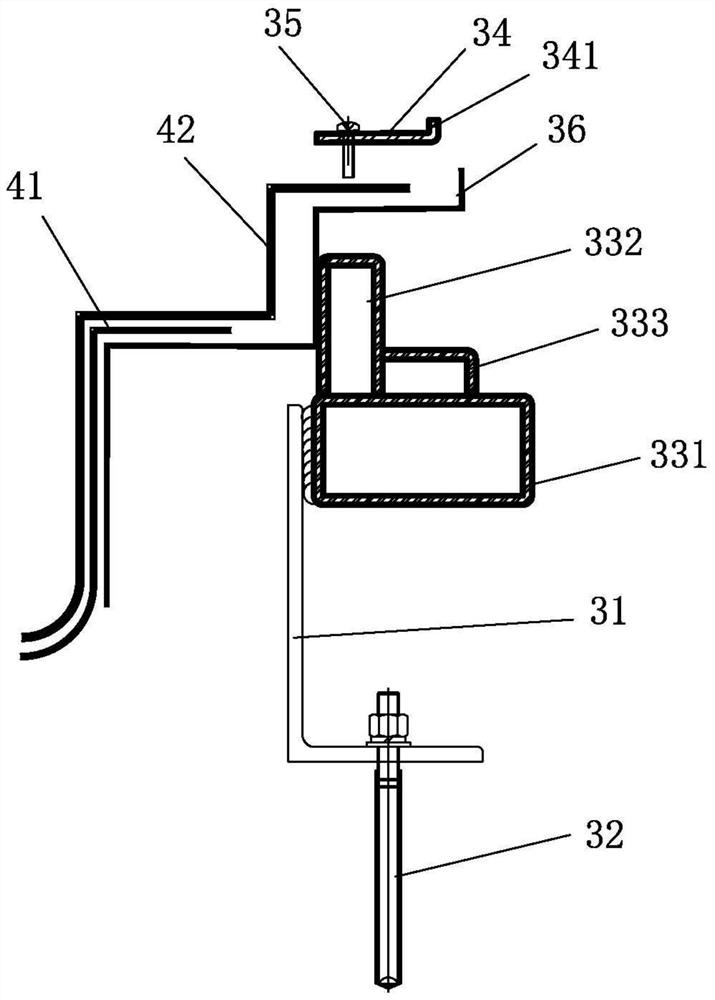

[0029] The lighting roof device 30 includes: angle steel base 31, expansion bolts 32, stepped steel frame components 33, waterproof fittings 34, fasteners 35, stainless steel waterproof plates 36 and lighting composite glass 37, the angle steel base 31 passes through the expansion bolts 32 Fixed on the structural floor 10, the stepped stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com