Atomizing sheet driving framework and driving method

A technology of atomizing sheet and driving device, which is applied in the direction of heating method, AC motor control, lighting and heating equipment, etc., can solve the problems of low negative phase voltage, easy to burn out, high positive phase voltage, etc., achieve high conversion efficiency and reduce certification Time and authentication cost, low power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

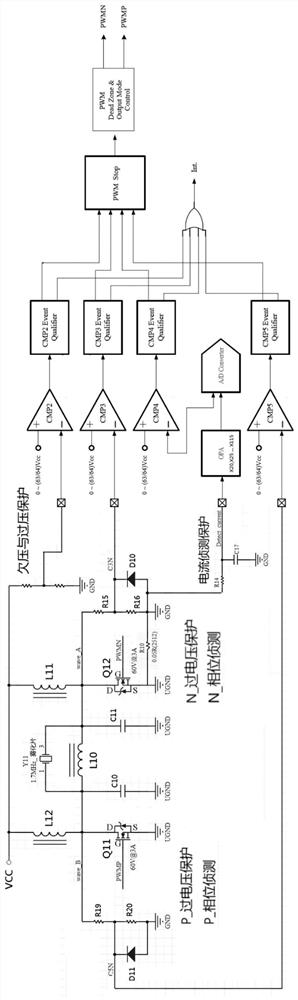

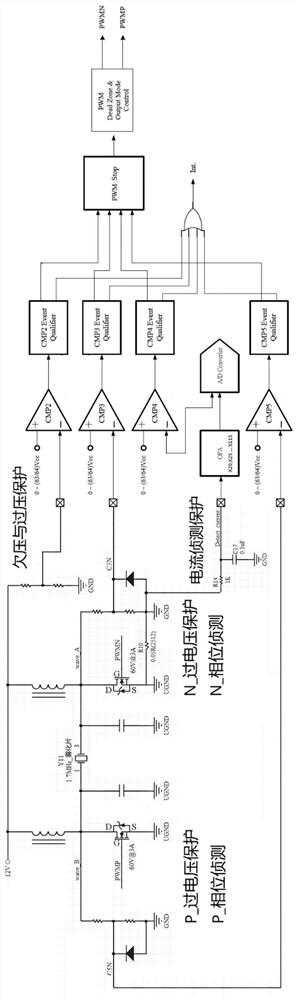

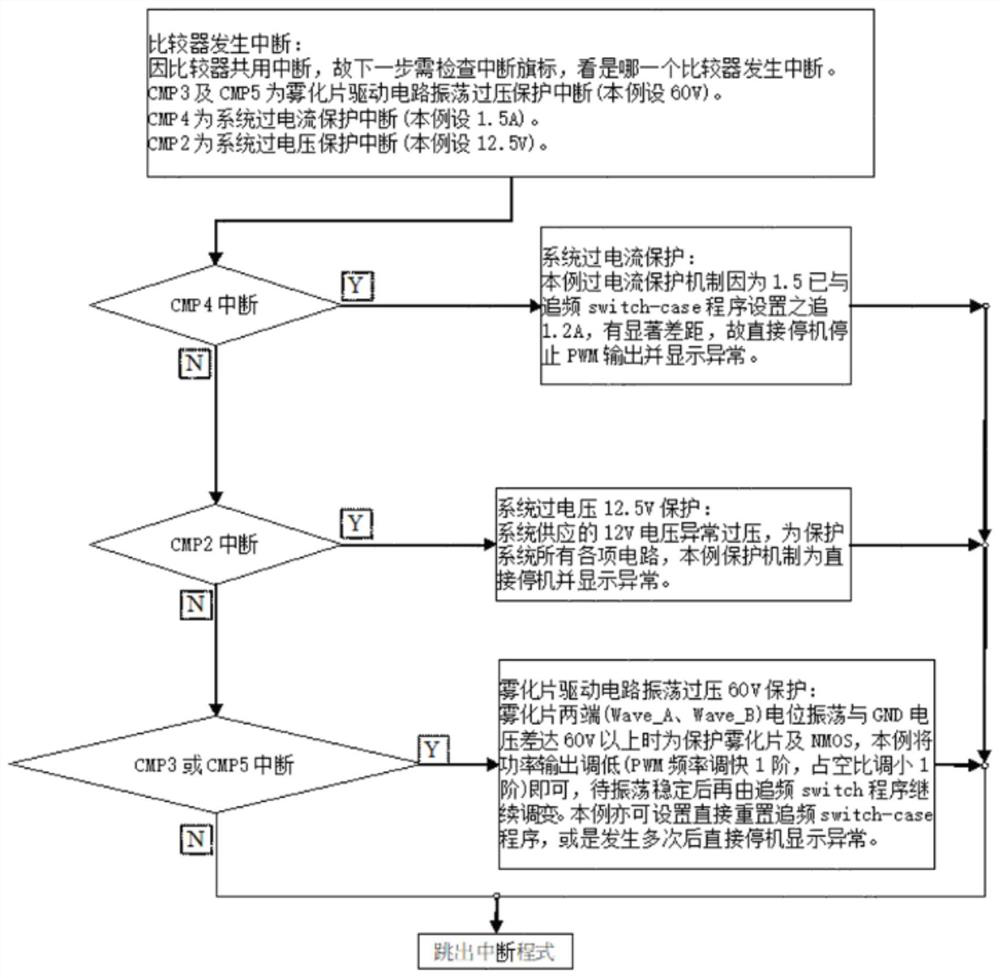

[0057] Example: such as figure 1 As shown, an atomizing sheet driving structure is characterized in that: it includes a driving device and an atomizing sheet, and the driving device pushes the atomizing sheet to reach a frequency of vibration by means of its exciting vibration, and a single power supply is used in the driving device to drive the atomizing sheet , the driving device includes various voltage protection structures, phase detection protection structures, and overcurrent protection structures. The voltage protection structure performs voltage detection. When the boost potential exceeds the set value, all actions are turned off. Detection, when a phase abnormality occurs, various protection operations can be performed immediately or all actions can be shut down immediately. The over-current protection structure performs potential monitoring and over-current protection, and all actions can be shut down when an over-current abnormality occurs.

[0058] An atomizer dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com