Automobile tire wear resistance intelligent test system and detection method thereof

A testing system and technology for automobile tires, applied in automobile tire testing, testing wear resistance, etc., can solve the problems of tire deflection, increase working time, low authenticity, etc., reduce the probability of error, improve the degree of stability, The effect of increasing realism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

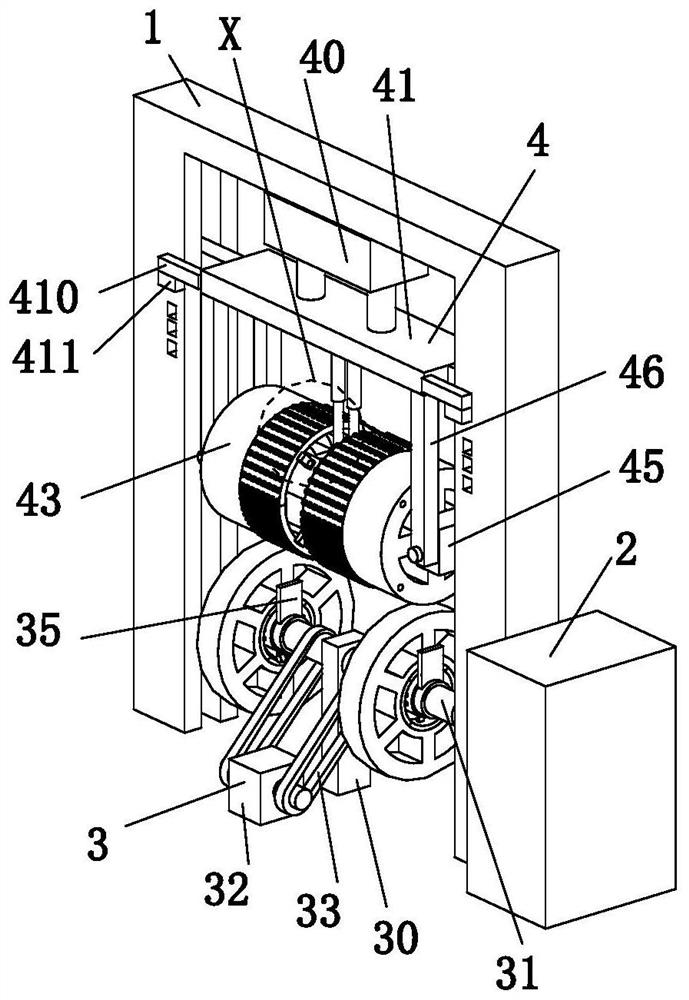

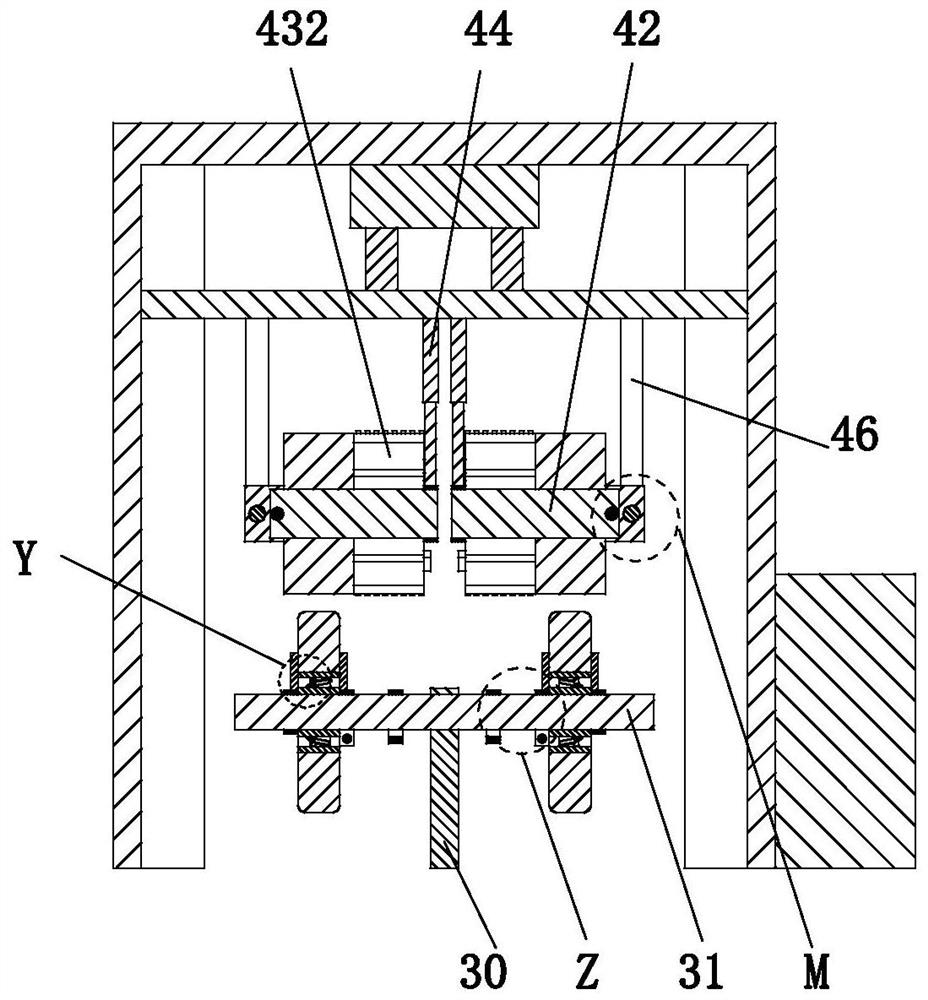

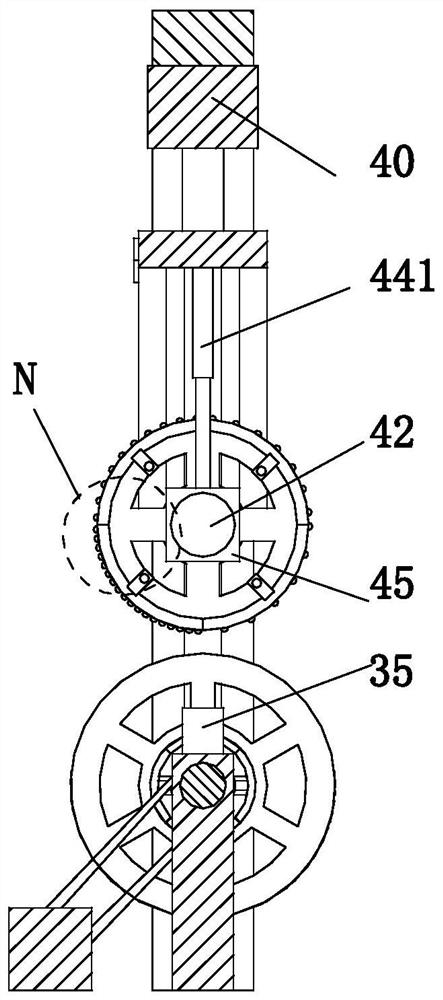

[0036] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 11 , to further elaborate the present invention.

[0037] An intelligent test system for automobile tire wear resistance, comprising a gantry 1, a display 2, a clamping mechanism 3 and a detection mechanism 4, the gantry 1 is installed on the existing working ground, and the lower right end of the gantry 1 is set There is a display instrument 2, the lower end of the display instrument 2 is installed on the existing working ground, the lower end of the gantry 1 is provided with a clamping mechanism, and the upper end of the gantry 1 is provided with a detection mechanism 4.

[0038] Described clamping mechanism 3 comprises intermediate frame 30, rotating shaft 31, biaxial motor 32, belt 33, built-in ring 34, baffle plate 35 and screw sleeve 36, and the lower end of intermediate frame 30 links to eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com