Method for quantitatively evaluating service life of material

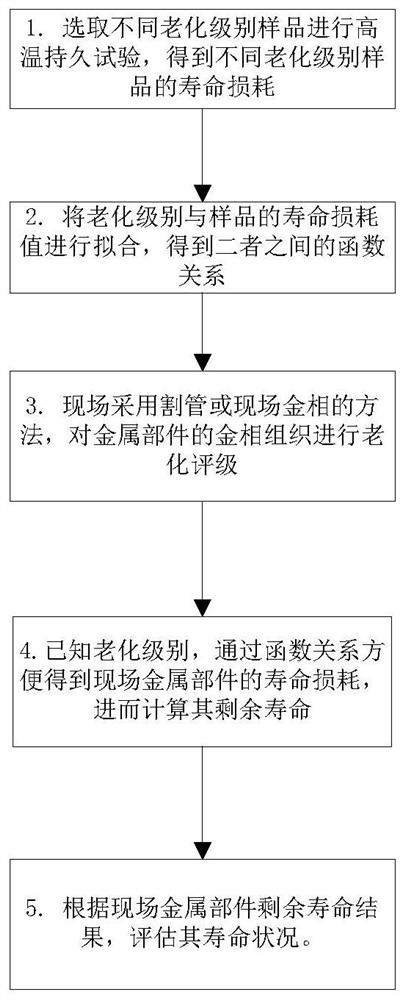

A quantitative evaluation and life-span technology, applied in the direction of analyzing materials, applying stable tension/pressure to test the strength of materials, measuring devices, etc., can solve the problems of inability to grasp the life status of metal parts, increase safety hazards, and take a long time to achieve Convenient and quick quantitative evaluation, solving the effects of long time-consuming and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

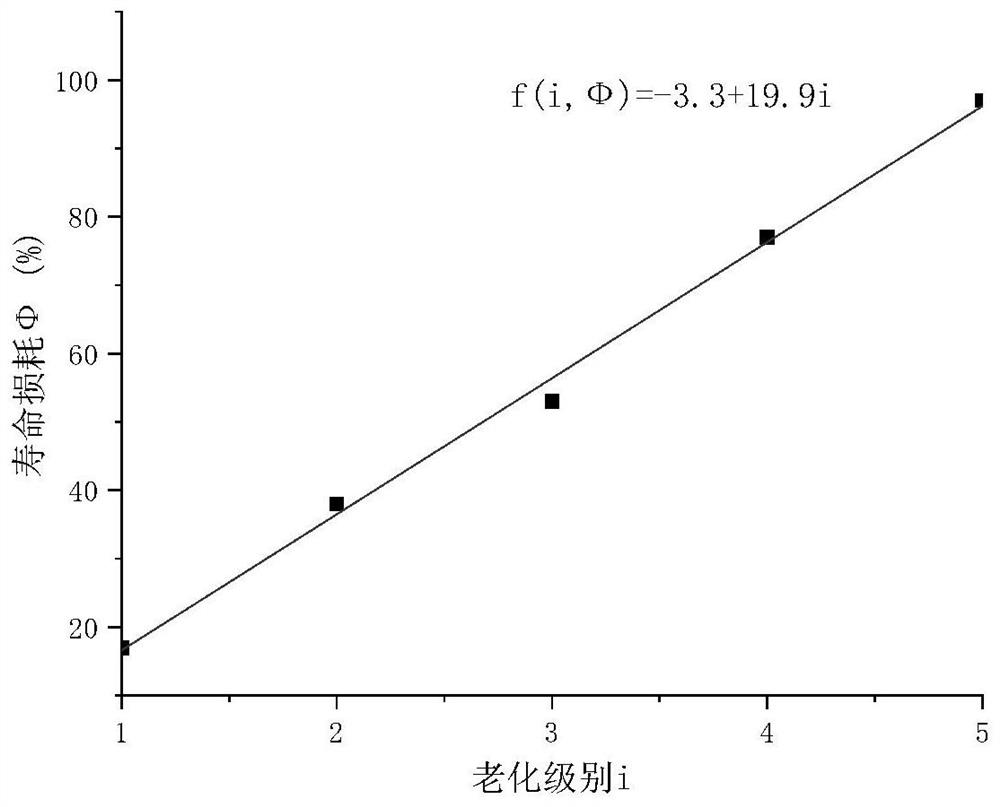

[0060] The aging level and life loss of pearlitic heat-resistant steel 12Cr1MoV are mathematically fitted. Table 1 shows the remaining life of samples with different aging levels:

[0061] Table 1 Durable life of different aging grades of 12Cr1MoV

[0062]

[0063] Fit the aging level and the life loss to obtain the functional relationship f(i,Ф) between the two, such as figure 2 shown.

Embodiment 2

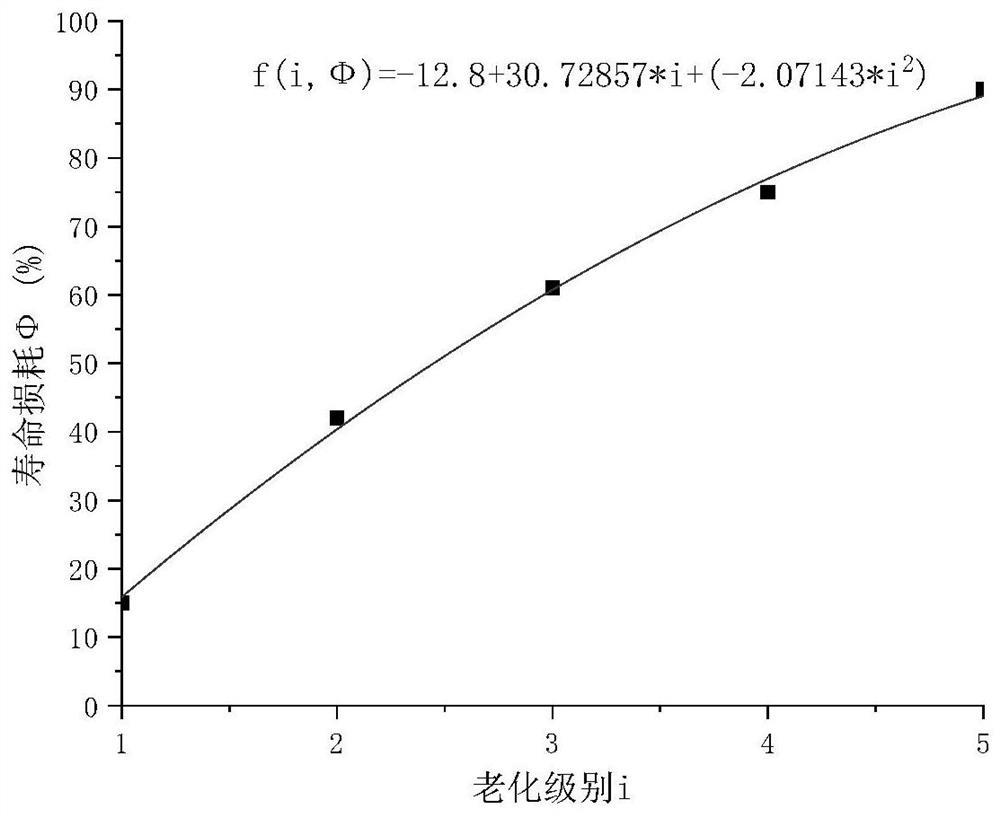

[0065] The life evaluation method for the martensitic heat-resistant steel T91 heating surface pipeline in service in the power plant is as follows:

[0066] Select unworn T91 samples and T91 samples with aging levels of 1 to 5 (according to DLT 884-2019 "Technical Guidelines for Metallographic Inspection and Evaluation of Thermal Power Plants" for aging level assessment) to conduct high-temperature endurance strength tests, high-temperature strength The temperature during the endurance test is 570°C, and the high-temperature endurance strength test is carried out under the conditions of pressures of 100MPa, 110MPa, 120MPa, 150MPa, 160MPa and 190MPa respectively, and the fracture time of the unworn samples and samples of different aging levels under different pressures are obtained , to establish the functional relationship between sample stress and fracture time, this function is the creep equation of samples with different aging levels.

[0067] Knowing the pipeline specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com