Novel OLED luminescent material for display equipment and preparation method of novel OLED luminescent material

A technology for light-emitting materials and display devices, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as low quantum efficiency, and achieve the effect of improving quantum efficiency and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

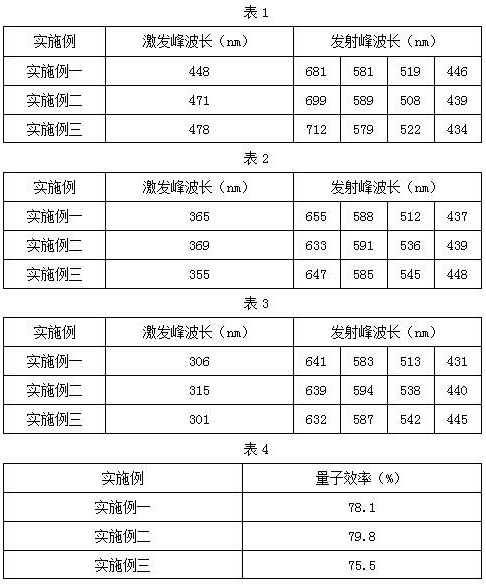

Examples

Embodiment 1

[0042] (1) 5 parts by mass of coronene, 3 parts by mass of anthraquinone, 5 parts by mass of N-allyl-4-bromo-1,8-naphthalimide, 10 parts by mass of p-chloropyrazoline Ketone, 5 parts by mass of resveratrol and 8 parts by mass of 8-hydroxyporphyrin aluminum were dissolved in 60 parts by mass of triethylamine, vacuumed 3 times, and reacted under nitrogen protection. The reaction temperature was controlled at 50°C. 8h, after the HPLC spot plate monitors that the reaction is complete, it is cooled to room temperature to obtain a reactant mixture 1;

[0043] (2) Add 20 parts by mass of dilute hydrochloric acid with a mass fraction of 5% to the reaction mixture one prepared in step (1), stir and mix well, filter, take the filtrate, and then add 40 parts by mass of acetic acid to the mother liquor Ethyl ester and 30 parts by mass of water solution, the water phase was washed twice with ethyl acetate, the organic phases were combined, dried with anhydrous magnesium sulfate, and then c...

Embodiment 2

[0054] (1) 8 parts by mass of coronene, 4 parts by mass of anthraquinone, 6 parts by mass of N-allyl-4-bromo-1,8-naphthalimide, 11 parts by mass of p-chloropyrazoline Ketone, 7 parts by mass of resveratrol and 9 parts by mass of 8-hydroxyporphyrin aluminum were dissolved in 70 parts by mass of triethylamine, vacuumed 3 times, and reacted under nitrogen protection. The reaction temperature was controlled at 55°C. After 9h, HPLC spot plate monitors that the reaction is complete, and then cools to room temperature to obtain a reactant mixture 1;

[0055] (2) Add 22 parts by mass of dilute hydrochloric acid with a mass fraction of 5% to the reaction mixture one prepared in step (1), stir and mix well, filter, take the filtrate, and then add 50 parts by mass of acetic acid to the mother liquor Ethyl ester and 40 parts by mass of water solution, the water phase was washed twice with ethyl acetate, the organic phase was combined, dried with anhydrous magnesium sulfate, and then conce...

Embodiment 3

[0066] (1) 10 parts by mass of coronene, 5 parts by mass of anthraquinone, 8 parts by mass of N-allyl-4-bromo-1,8-naphthalimide, 12 parts by mass of p-chloropyrazoline Ketone, 8 parts by mass of resveratrol and 10 parts by mass of 8-hydroxyporphyrin aluminum were dissolved in 80 parts by mass of triethylamine, vacuumed 3 times, and reacted under nitrogen protection. The reaction temperature was controlled at 60°C. After 10 h, after HPLC spot plate monitoring reaction is complete, cool to room temperature to obtain reactant mixture 1;

[0067] (2) Add 25 parts by mass of dilute hydrochloric acid with a mass fraction of 5% to the reaction mixture one prepared in step (1), stir and mix well, filter, take the filtrate, and then add 50 parts by mass of acetic acid to the mother liquor Ethyl ester and 40 parts by mass of water solution, the water phase was washed twice with ethyl acetate, the organic phase was combined, dried with anhydrous magnesium sulfate, and then concentrated t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com