Sealing damping sheet, sealing device, sealing structure, shell and motor

A sealing device and sealing structure technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems affecting the sealing of the motor and the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

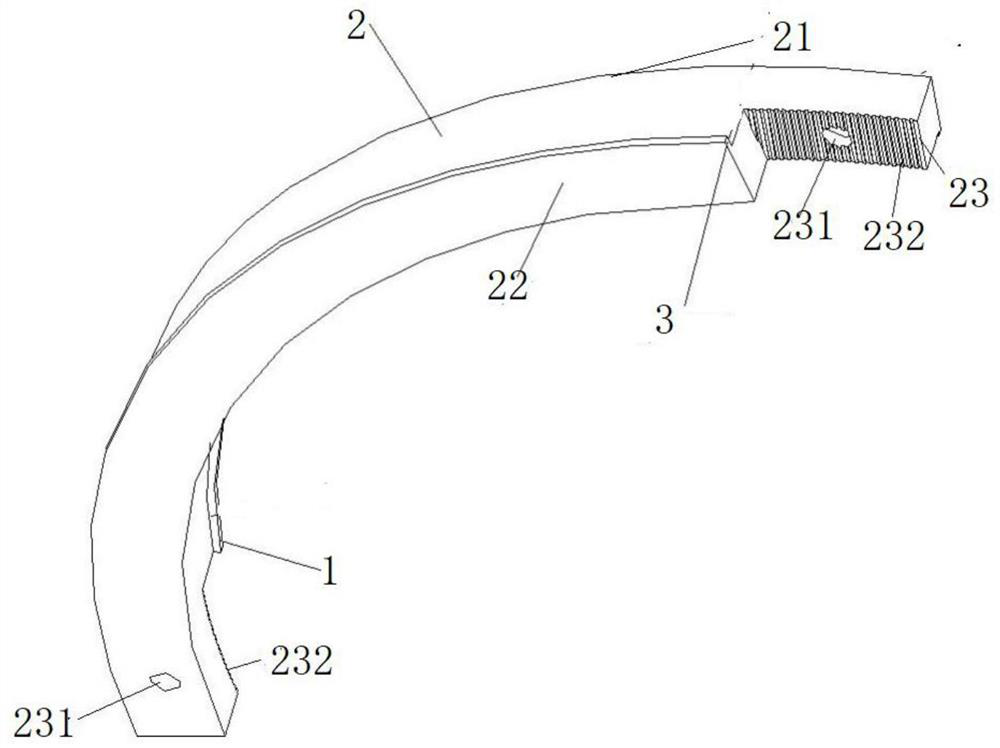

[0040] Such as figure 1 As shown, the present embodiment provides a sealed shock absorbing sheet, which includes a sealing body, the sealing body is integrally formed with a sealing body, and the sealing body is integrally formed with a first sealing part 1, a second sealing part 2 and a third sealing part. Part 3, wherein the first sealing part 1 is used to seal the first gap 6, the third sealing part 3 is used to seal the second gap 7, and the second sealing part 2 is located between the first sealing part 1 and the third sealing part 3, It is used to seal and isolate the first gap 6 and the second gap 7; the hardness of the second sealing part 2 is greater than that of the first sealing part 1 and the third sealing part 3 respectively.

[0041] This embodiment provides a sealing and shock absorbing sheet, the sealing and shock absorbing sheet has a first sealing part, a second sealing part and a third sealing part, which can realize triple sealing between the gaps, and the ...

Embodiment 2

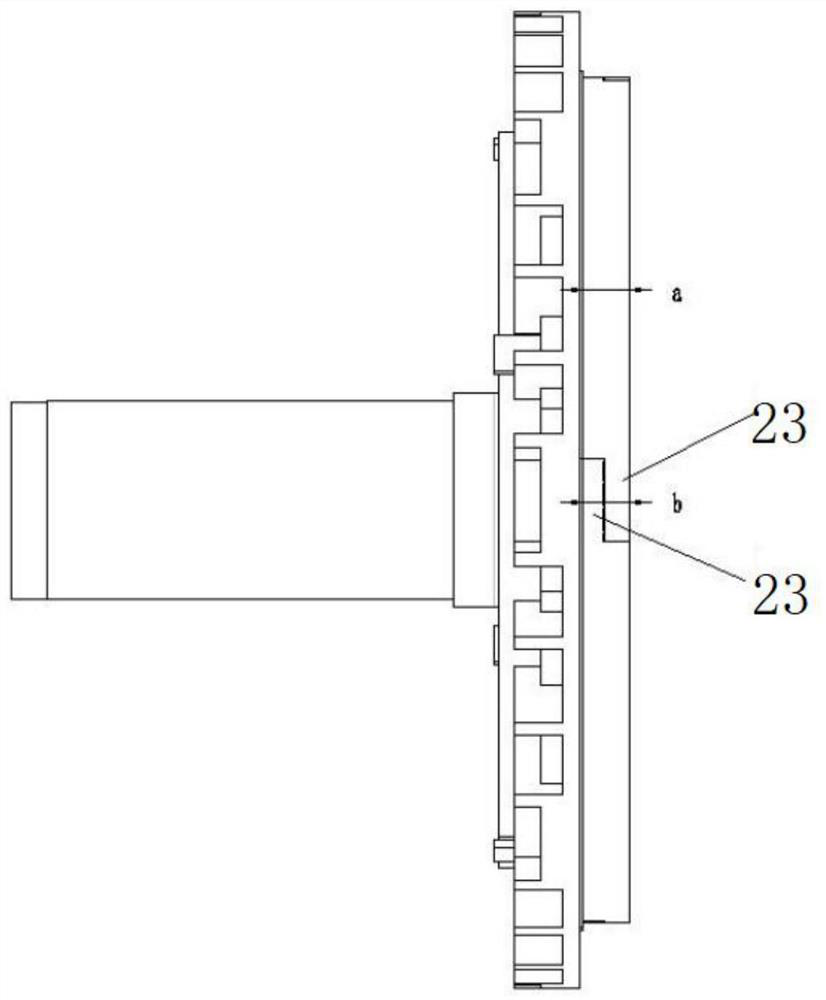

[0047] Such as image 3 As shown, this implementation provides a sealing device, which has the sealing and damping sheet in Embodiment 1, and the number of sealing and shock absorbing sheets is not less than two. Preferably, different sealing and shock absorbing sheets are connected by fasteners 8 .

[0048] Preferably, the sealing device is a sealing ring.

[0049] The sealing device provided in this embodiment is formed by splicing multiple arc-shaped sealing and shock absorbing sheets. The radian, quantity and thickness of the sealing and shock absorbing sheets can be determined according to the size of the specific shell structure, so it is universal and applicable. powerful. The sealing sheet has lower requirements on the mold, and the mold investment cost is low. Among them, there are dense anti-slip protrusions on the splicing surface between the sealing and shock-absorbing sheets and between the second sealing and connecting parts, which enhances the bonding force b...

Embodiment 3

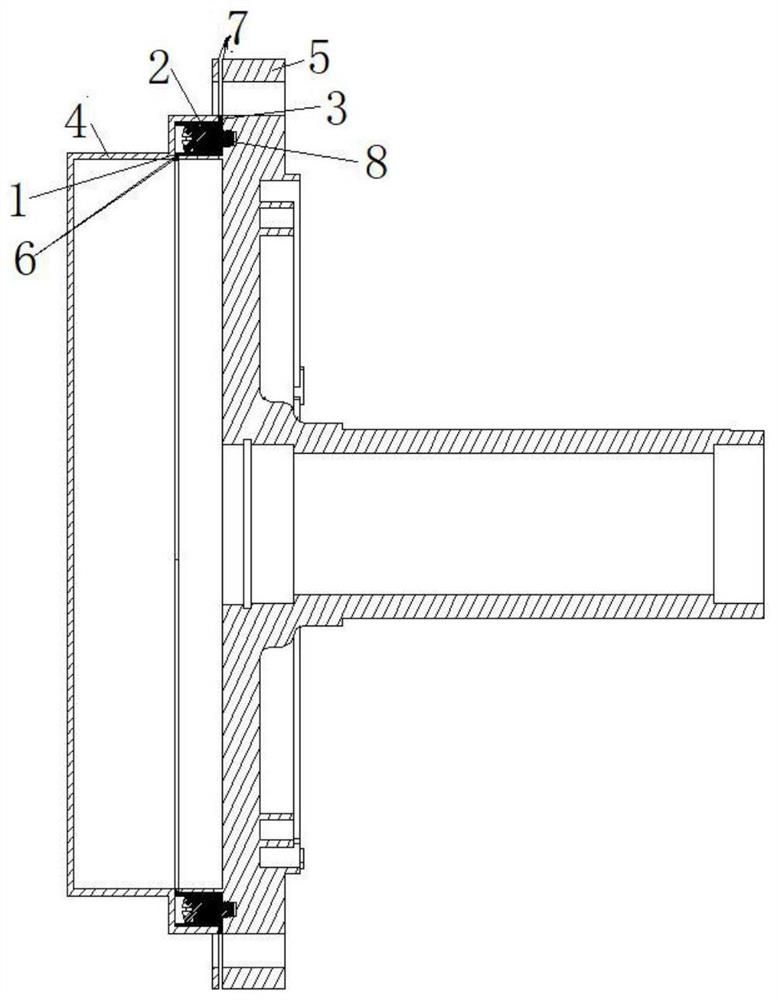

[0051] Such as figure 2 As shown, the present embodiment provides a motor, which includes a housing, wherein the housing includes a sealing structure, which includes a first housing 4 and a second housing 5, and is used to seal the first housing 4 and the second housing 5. The sealing shock absorbing sheet between the second housing 5; the sealing shock absorbing sheet is the sealing shock absorbing sheet in embodiment 1 or the sealing device in embodiment 2; the first housing 4 and the second housing 5 are respectively formed with The first assembly surface and the second assembly surface, wherein the first assembly surfaces of the two are fitted together to form a first gap, and the second assembly surfaces of the two are fitted together to form a second gap.

[0052] Preferably, the first housing 4 is formed with a cavity along the upper edge; the second housing 5 is formed with an extension; after the first housing 4 and the second housing 5 are assembled, the extension i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com