Water-cooled structure of reflow soldering furnace and wind motor and reflow soldering furnace

A technology for wind motors and reflow ovens, which is applied in wind power generation, electrical components, electromechanical devices, etc., which can solve the problems of inconvenience and easy burnout of wind motors, so as to avoid overheating, reduce maintenance costs, and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

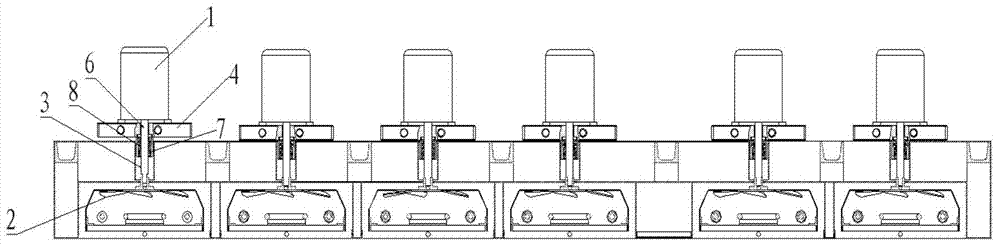

[0038] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following will be combined with the accompanying drawings and preferred embodiments to describe the water-cooled structure of the reflow oven motor and the specific implementation of the reflow oven according to the present invention. , structure, feature and effect thereof, detailed description is as follows. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

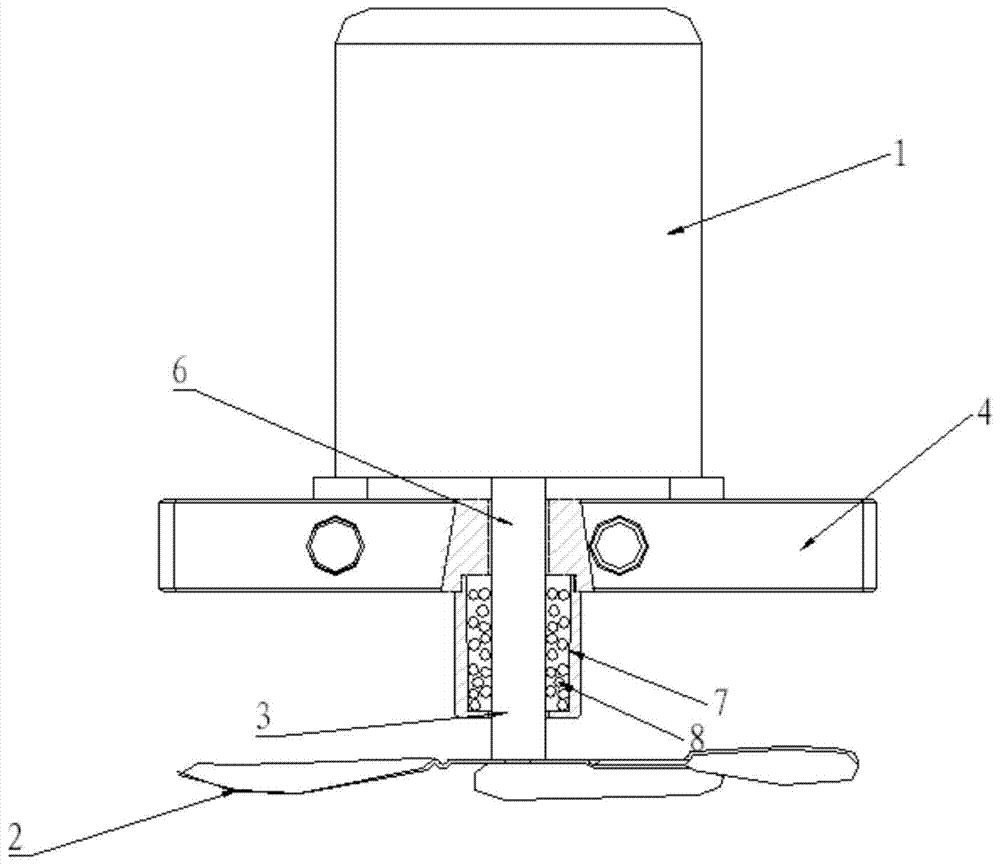

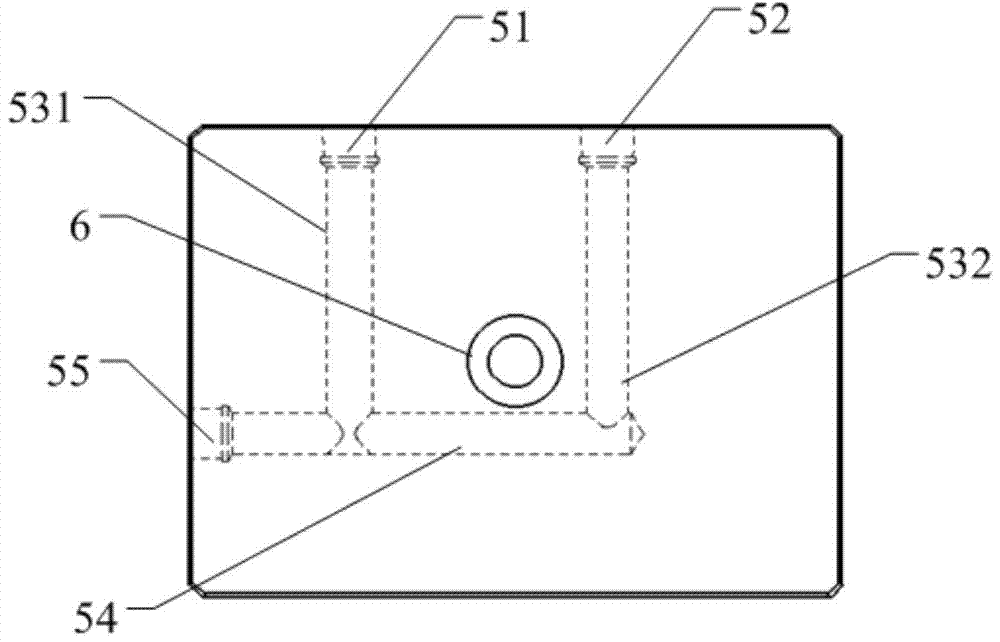

[0039] The present invention provides a water-cooling structure for a reflow soldering furnace wind motor, comprising a water-cooled aluminum base 4, a motor shaft hole 6 is provided in the middle of the water-cooled aluminum base 4, and a wind-running motor 1 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com