Groove-type rare earth permanent magnet brushless motor

A rare-earth permanent magnet and brushless motor technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as failure to issue alarms in time, motor damage, and potential safety hazards, so as to prevent damage from long-term overspeed rotation and improve use. Longevity, easy and timely processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

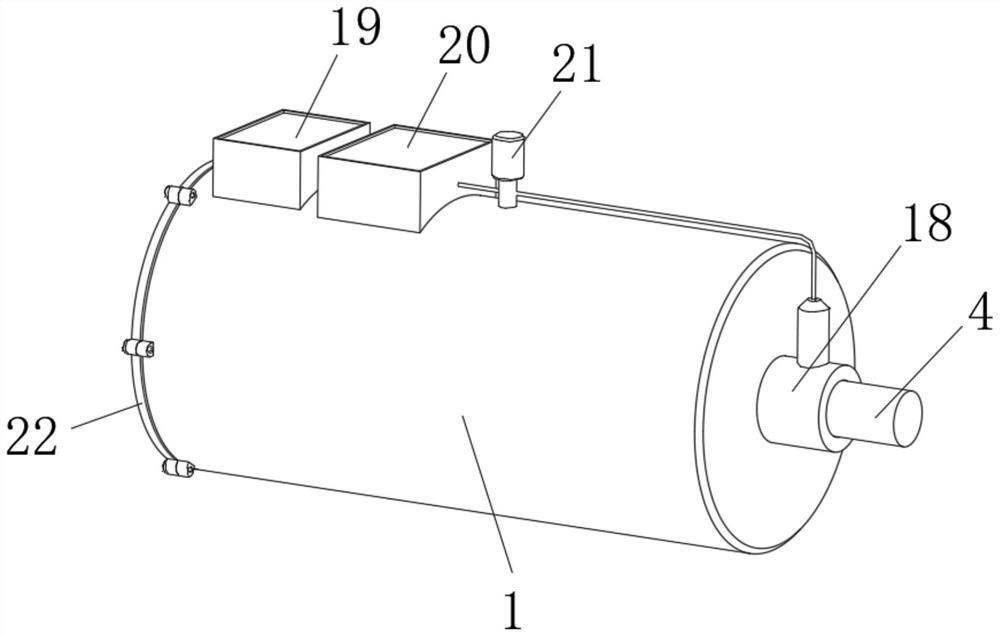

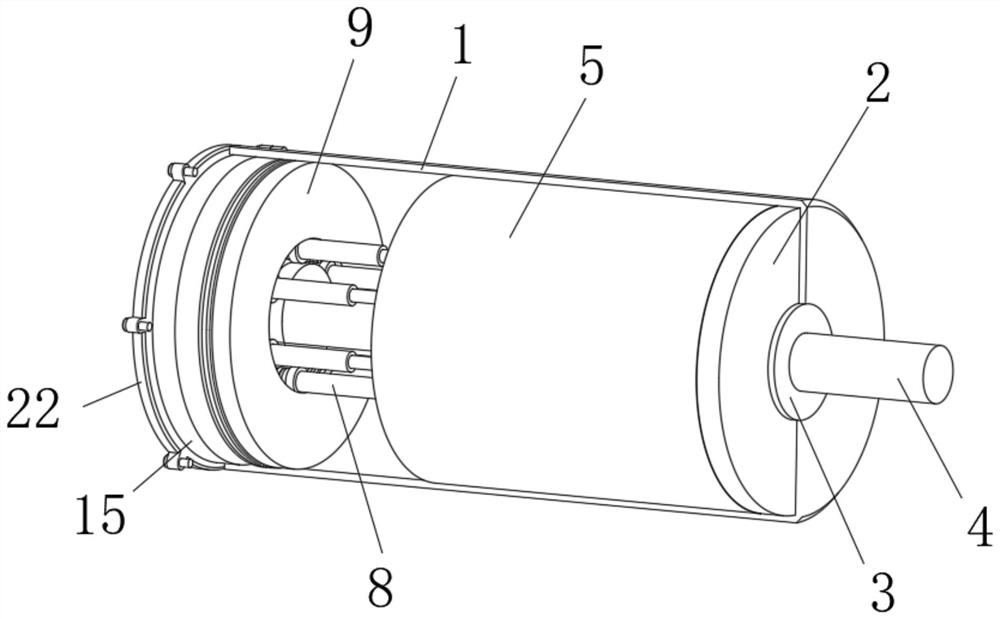

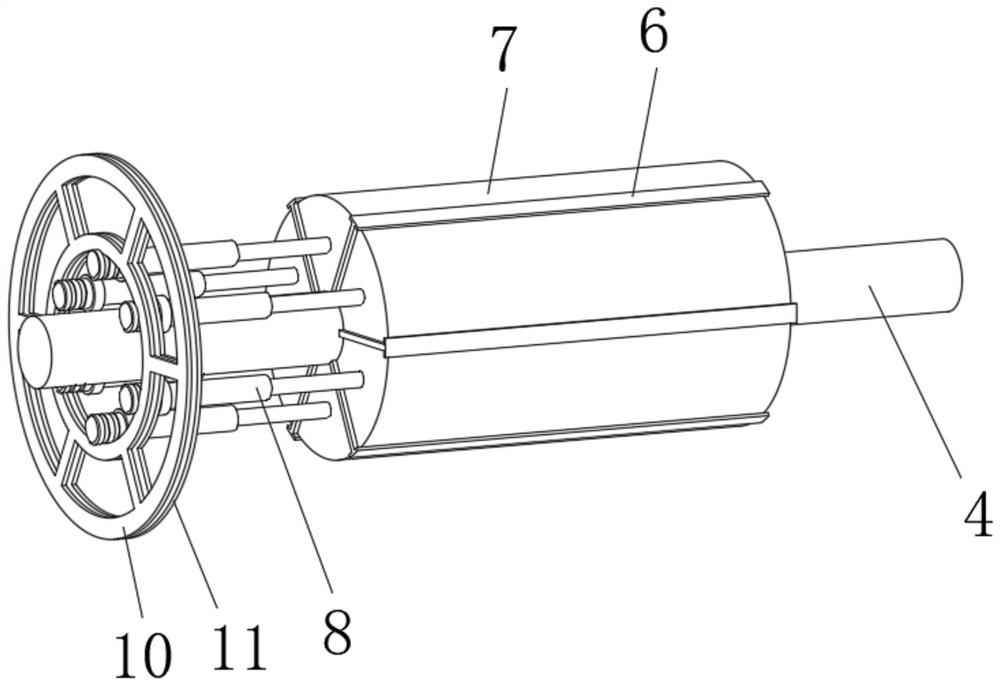

[0025] see Figure 1 to Figure 7, the present invention provides a technical solution: a slot-type rare earth permanent magnet brushless motor, including a motor housing 1, a right side bearing support 2 is fixedly installed on the right side inside the motor housing 1, and the right side bearing support 2 The middle fixed sleeve has a ball bearing 3, the middle fixed sleeve of the ball bearing 3 has a drive shaft 4, the inner fixed sleeve of the motor housing 1 has a stator 5, and the inside of the stator 5 is wound with a winding wire 13, and the external fixed installation of the drive shaft 4 is limited. The limit splint 6, and the inside of the limit splint 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com