Ramp actuator and angular-contact ball bearing unit with a cold-worked outer ring and an embossed ramp contour, and method for producing a ramp disc

A technology of actuators and rolling bearings, which is applied in the or motor field, can solve problems such as high cost and long time consumption, and achieve the effects of avoiding tilt, optimizing force application, and good functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

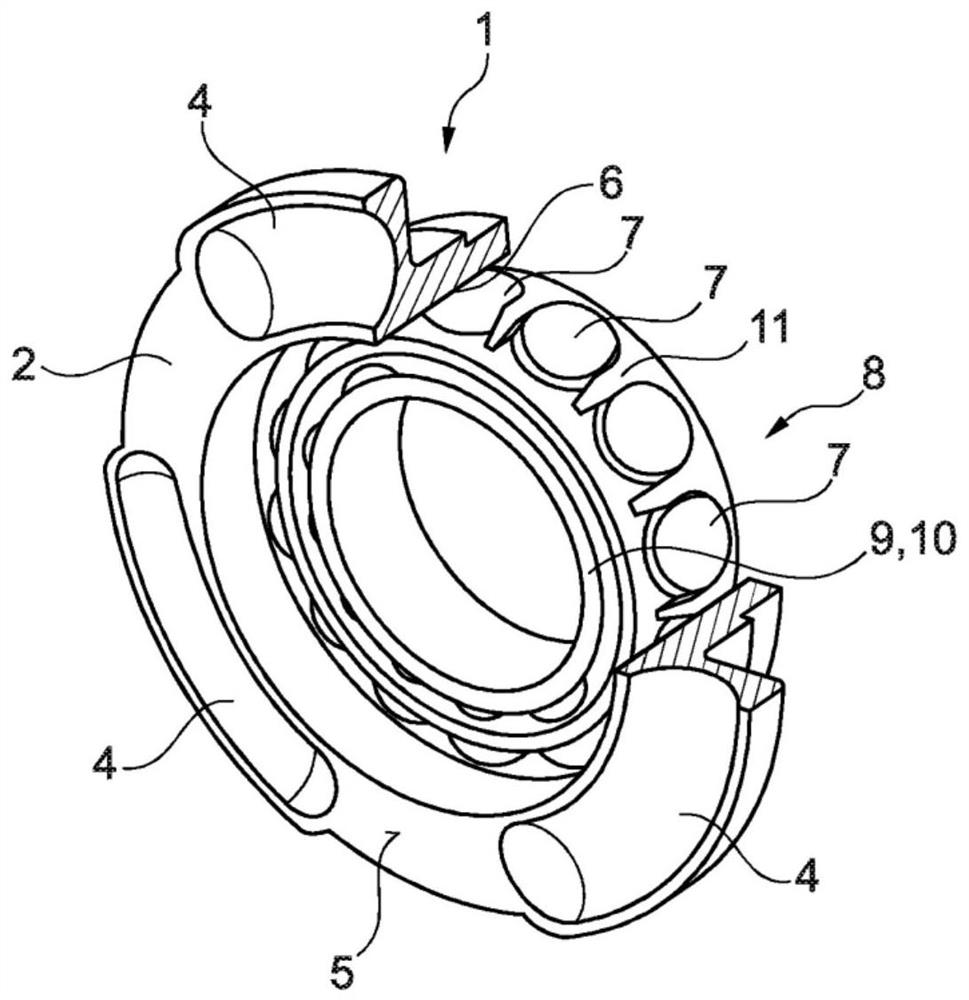

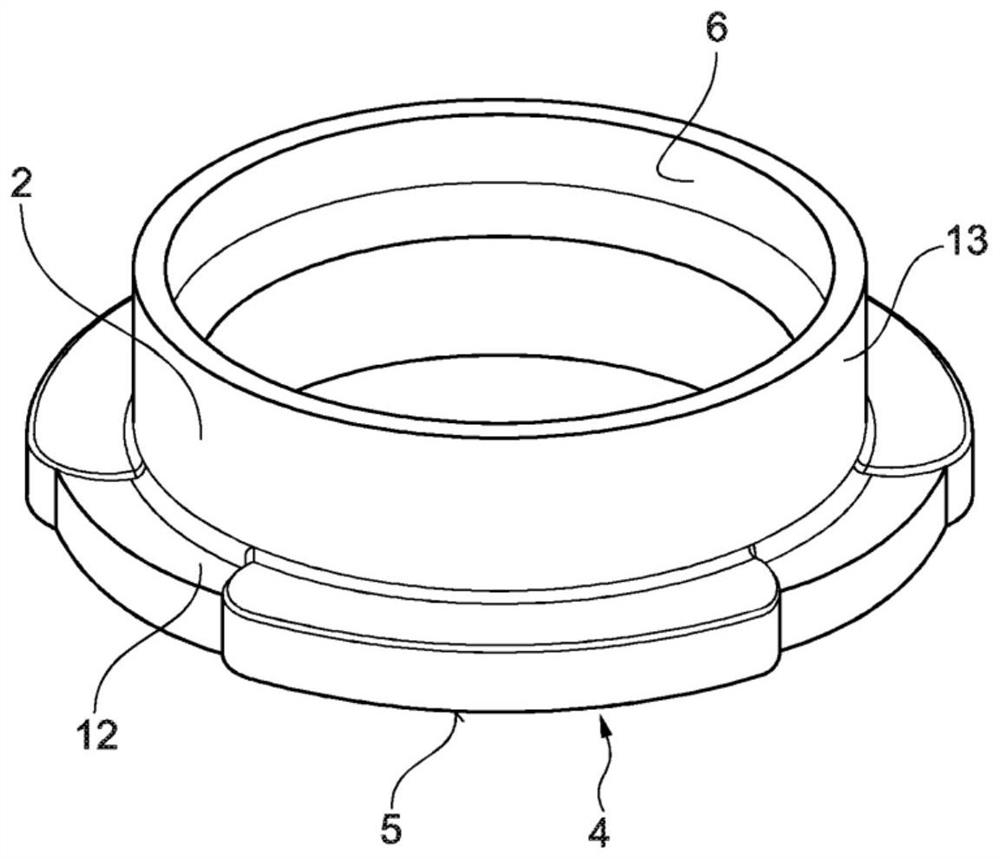

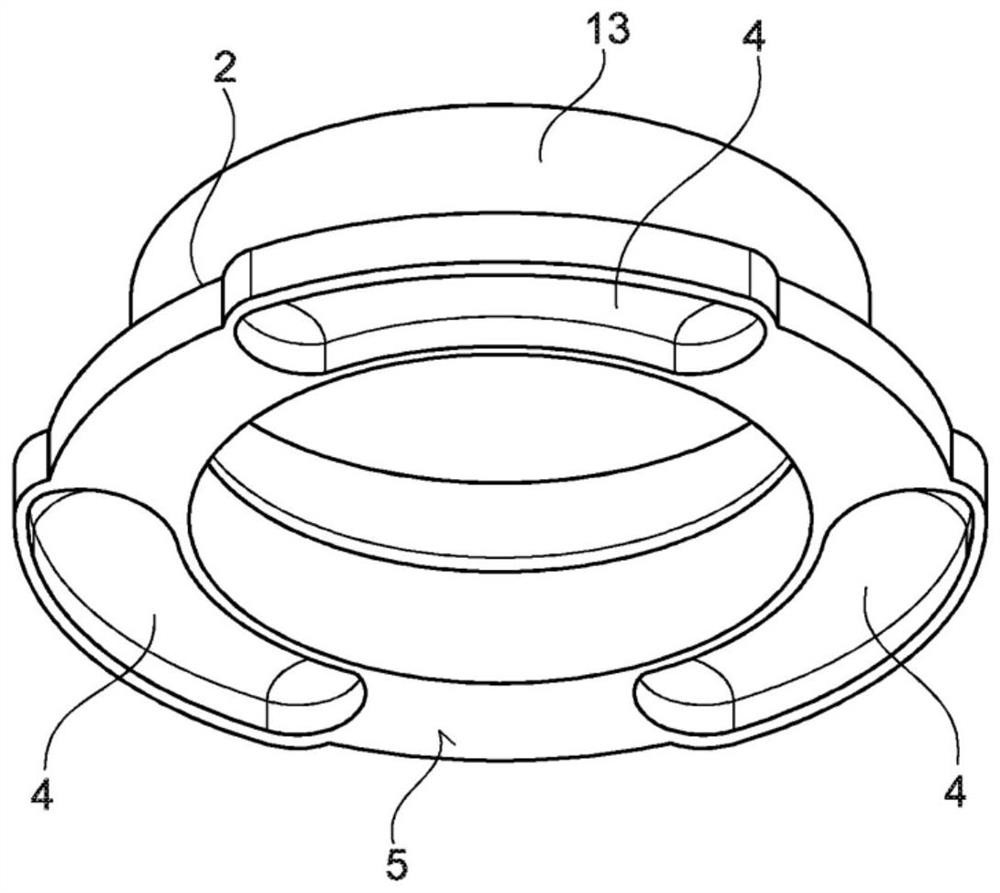

[0035] figure 1 A first exemplary embodiment of a ramp actuator 1 according to the invention is shown. The ramp actuator 1 has a pivotable ramp disk 2 . The ramp disk 2 may also be referred to as a pivotable ramp ring or pivot actuator disk. exist Figure 10 In anticipation, reference is made to tooth segments 3 designed as teeth or protrusions for coupling the motor.

[0036] back figure 1 , attention should be paid to the presence of the ramp 4 on the first end face 5 or the first end face. To be precise, there are three segmented ramps 4 with concave surfaces for receiving one or more balls, for example two, three, four or five balls. These balls are not shown.

[0037] At a distance there is a raceway 6 on which the bearing rolling bodies 7 have rolling bearings 8 which are equipped to receive radial and axial forces. The rolling bearing 8 also has a bearing ring 9, ie a bearing inner ring 10, which is equipped for mounting / fixing on the shaft. The shaft is not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com