Chicken bone removing device for preparing black-bone chicken meat powder

A technology of chicken powder and chicken, applied in the application, processing of meat, poultry deboning, etc., can solve the problems of low efficiency, easy scissors, safety accidents and other problems in the deboning of chicken leg meat, so as to improve the deboning effect and reduce labor Strength, safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

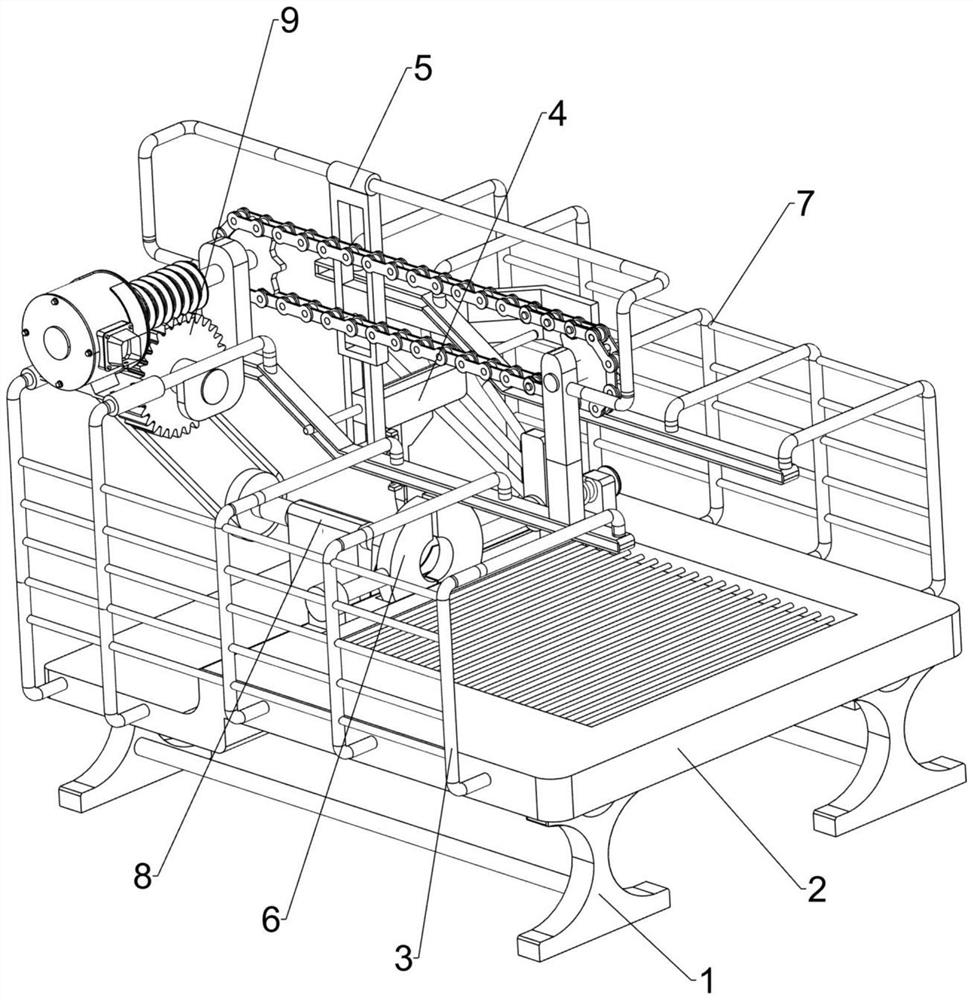

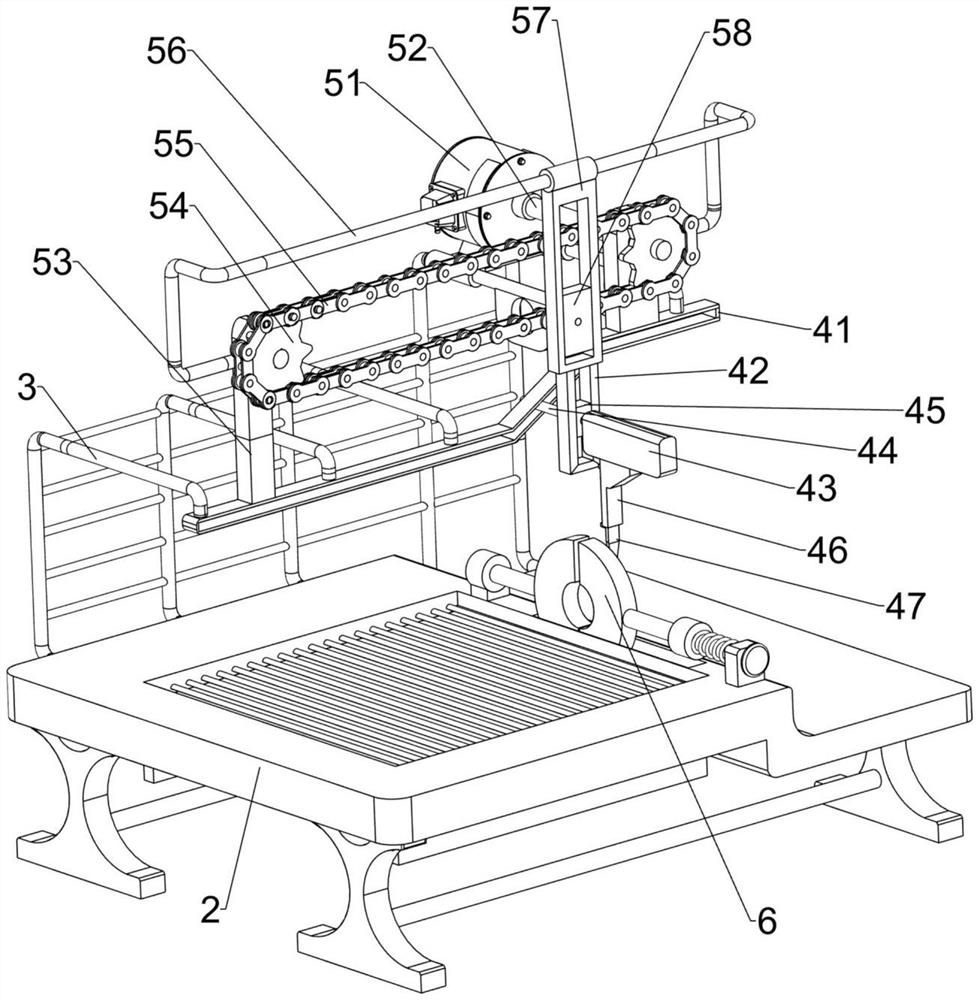

[0027] A kind of chicken deboning equipment for the preparation of black-bone chicken powder, such as Figure 1 to Figure 3 As shown, it includes a leg 1, a base 2, a first mounting frame 3, a splitting mechanism 4 and a horizontal reciprocating mechanism 5, the bottom of the base 2 is connected to the leg 1, and the top front side of the base 2 is connected to the first mounting frame 3. A horizontal reciprocating mechanism 5 and a splitting mechanism 4 are installed on the first installation frame 3 , and the horizontal reciprocating mechanism 5 and the splitting mechanism 4 are in transmission cooperation.

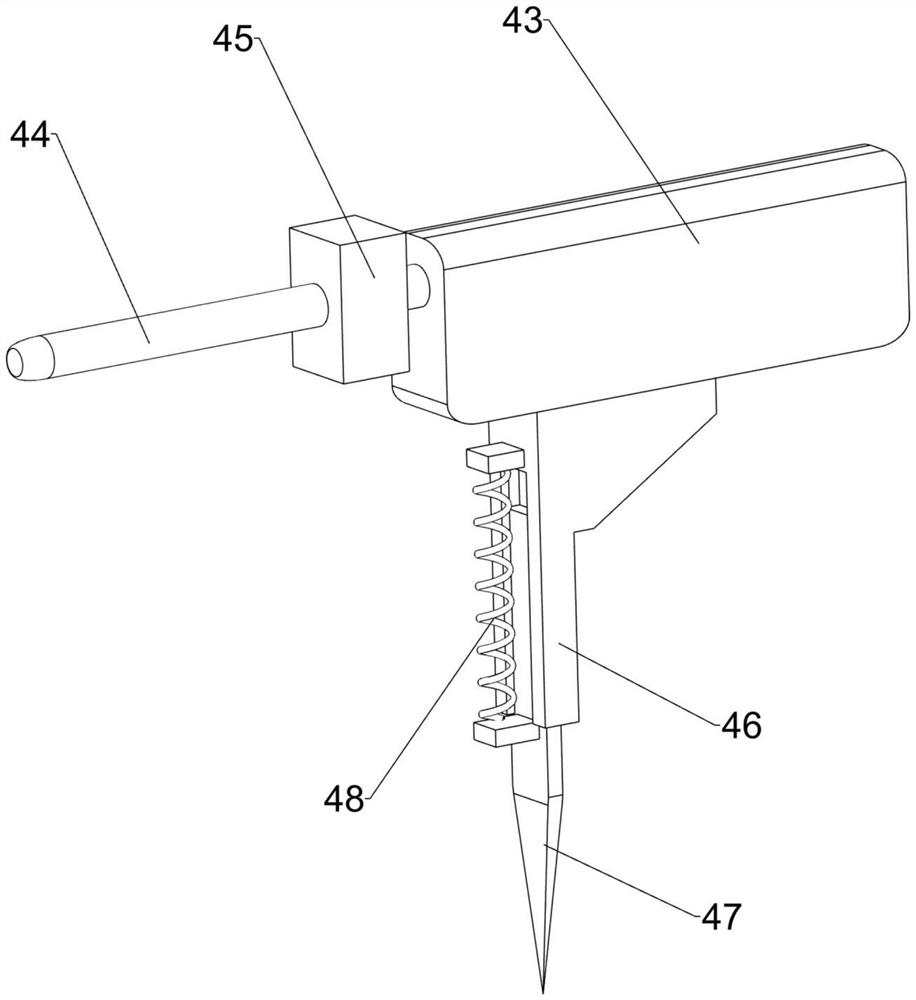

[0028] Dissection mechanism 4 comprises the first Z type slide rail 41, guide rail 42, fixed block 43, the first guide bar 44, the first sliding block 45, knife rest 46, pointed blade 47 and the first telescopic spring 48, the first installation The upper rear side of the frame 3 is connected with a first Z-shaped slide rail 41, and the first Z-shaped slide rail 41 is s...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 4 As shown, a clamping assembly 6 is also included. The clamping assembly 6 includes a fixed rod 61, a semicircular clamp 62, a sliding rod 63 and a second telescopic spring 64. The left front part of the base 2 is equipped with a fixed rod 61, and the base 2 The left side rear portion is slidably connected with a slide bar 63, the front end of the slide bar 63 and the rear end of the fixed bar 61 are connected with a semicircular clamp 62, the second telescopic spring 64 is connected between the slide bar 63 and the base 2, and the second telescopic spring 64 is connected between the slide bar 63 and the base 2. Two telescopic springs 64 are sheathed on the outside of the sliding rod 63 .

[0033] When the chicken legs need to be cut open, pull the slide bar 63 backwards, the semicircular clamps 62 on the rear side move backwards, the second telescopic spring 64 is compressed, and then the chicken legs are placed between the s...

Embodiment 3

[0037] On the basis of Example 2, such as Figure 5 As shown, a cutting mechanism 8 is also included, and the cutting mechanism 8 includes a second fixing plate 81, a second shaft rod 82, a connecting block 83 and an arc-shaped blade 84, and the top left side of the base 2 is connected with a second fixing plate 81 , the second fixed plate 81 is rotatably connected with a second shaft 82 , the right end of the second shaft 82 is connected with a connecting block 83 , and the connecting block 83 is connected with an arc-shaped blade 84 .

[0038] One end of the small joint of the chicken leg is placed on the arc-shaped blade 84, then the chicken leg is fixed by the clamping assembly 6, the second shaft 82 is manually rotated, and the rotation of the second shaft 82 drives the connecting block 83 to rotate, and the arc-shaped blade 84 Rotating thereupon, the circular-arc blade 84 rotates and can cut one end of the small joint of the chicken leg in a circumscribed manner, and cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com