Waste gas treatment device in waste lithium battery treatment

A waste gas treatment device and waste lithium battery technology, applied in battery recycling, waste collector recycling, settling tanks, etc., can solve the problem of reducing the practicability of waste gas treatment devices, the inconvenience of replacing and fixing activated carbon plates, and the inability to recycle treatment liquid, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

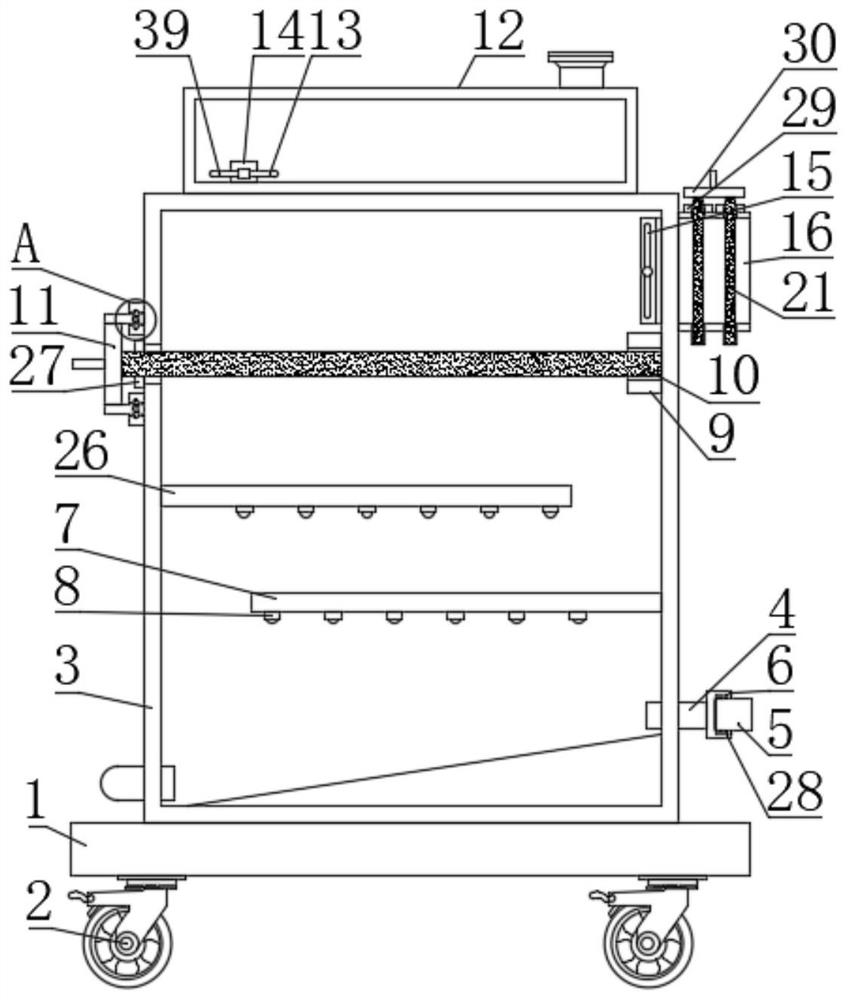

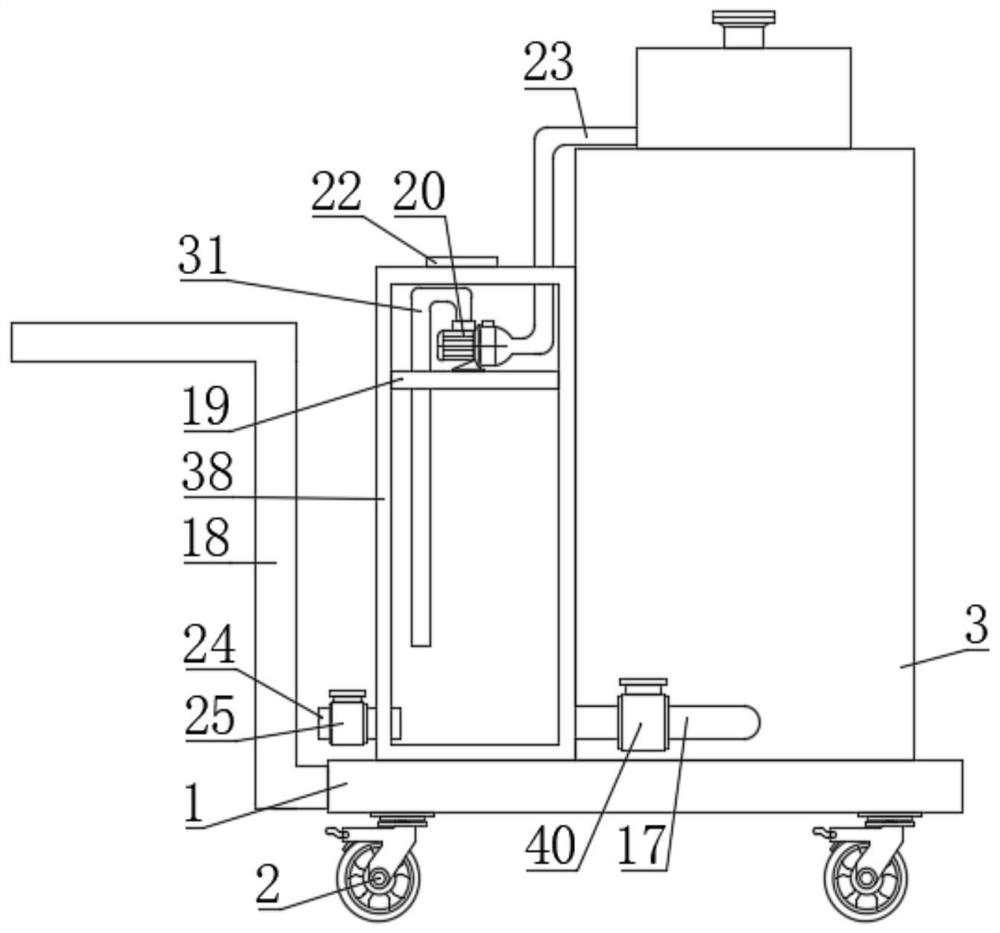

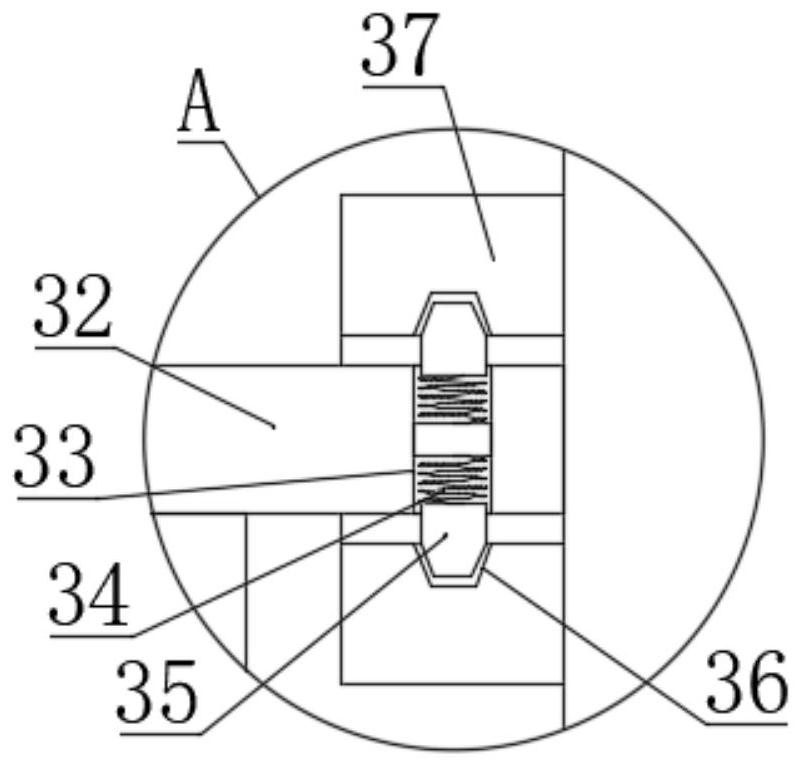

[0023] The following is attached Figure 1-4 The present invention is described in further detail.

[0024] see Figure 1-4 , the present invention provides a technical solution: a waste gas treatment device in the treatment of waste lithium batteries, such as Figure 1-4 As shown, including the base 1, the top of the base 1 is provided with a treatment box 3 and a sedimentation box 38, one side of the treatment box 3 is provided with a fixed block 37 and a first sealing ring 27, and the inside of the fixed block 37 is provided with a draw-in groove 36, The inner wall of the treatment box 3 is respectively provided with a first water transfer board 7 and a second water transfer board 26, and the bottoms of the first water transfer board 7 and the second water transfer board 26 are all connected with an atomizing nozzle 8, through which the first water transfer board 7 and the second water transfer board 26 are connected. The setting of the plate 7, the second water transfer ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap