Integrated paint spraying device for shoes

A technology for shoes and spray booths, which is applied in spraying devices and spray booths, etc. It can solve the problems of easy solidification and clogging of spray guns and paint spray circuits, low flexibility of spray paint, and poor stability, so as to improve operation accuracy and quality, and adjust layout Convenience and high operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

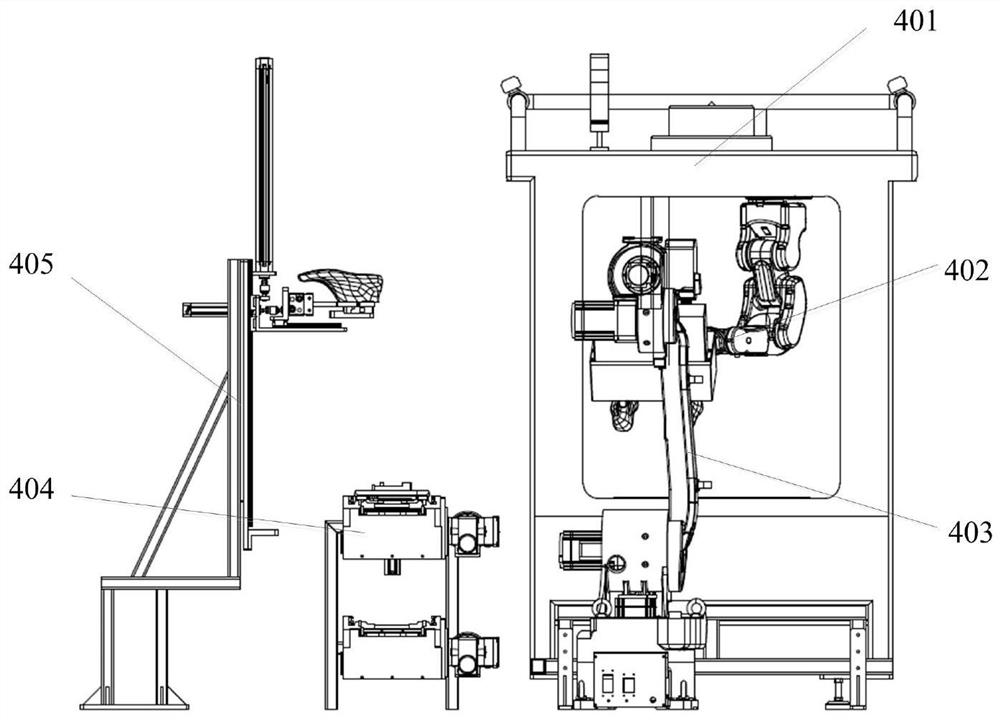

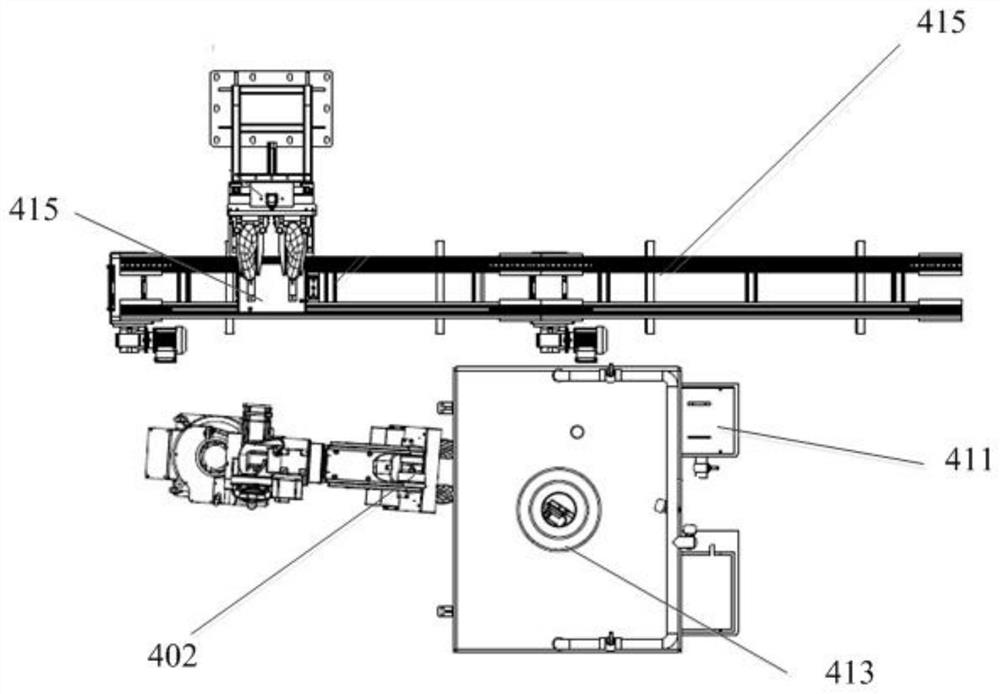

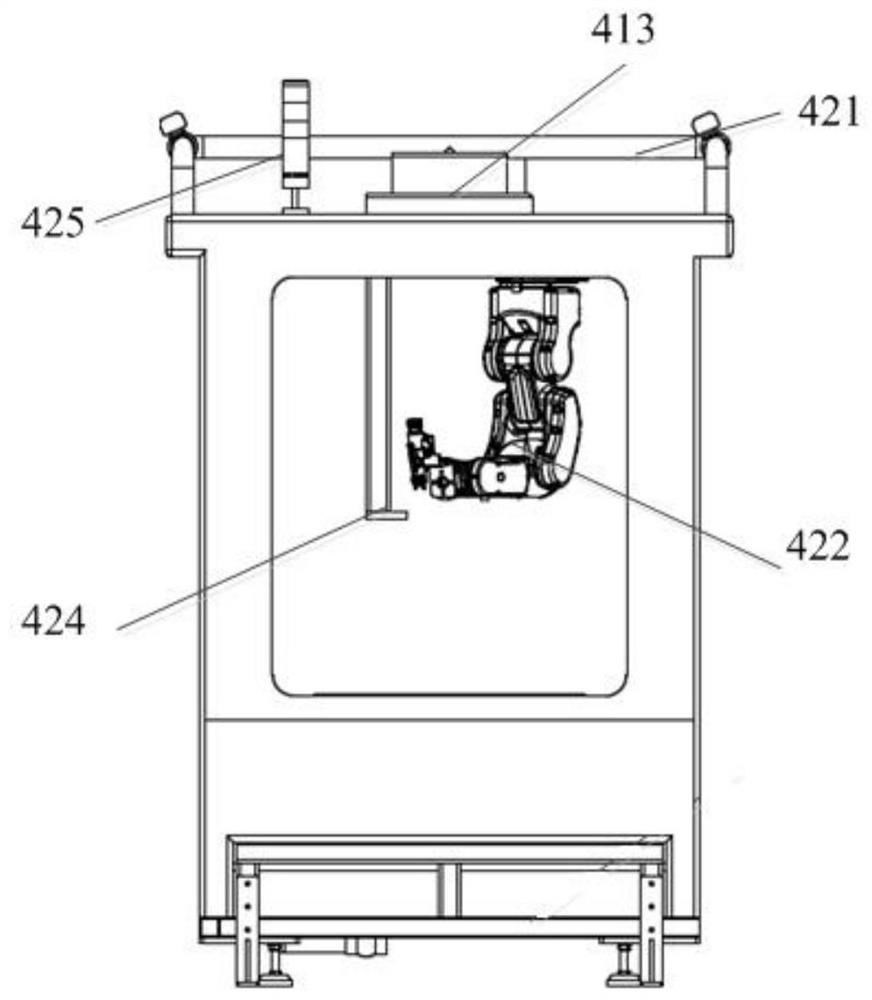

[0015] By the following Figure 1-5 The technical solutions of the present invention are further illustrated.

[0016] As shown in the figure, an integrated spray device comprising a clamping device 402 for clamping the shoe and a painting device 401 for painting the upper, the shoe spray device 401 further comprising a wire delivery device 404 and a line The line body conveying device 404 is used to increase the shoe from the line body conveying device 404 to a height boost device 405, the lifting device 405, and the wire delivery device 404 use a medium-sized load industry robot, the painting device 401 uses a small load. High-precision industrial robots, clamping devices 402 use a medium-sized load industrial robot, and a cleaning device is provided in the painting device 401.

[0017] The line body conveying device 404 is composed of a head driving portion, a tail, an aluminum profile, a photoelectric sensor, a roller, a top positioning mechanism, and the like. The head driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com