Linkage type straightening and cutting device based on wound alloy welding wire machining

A technology of alloy welding wire and cutting device, which is applied in the field of welding wire processing, and can solve the problems that the cutter is prone to bumping, the straightening structure of the welding wire cannot be elastically compressed and automatically locked, and sliding installation cannot be performed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

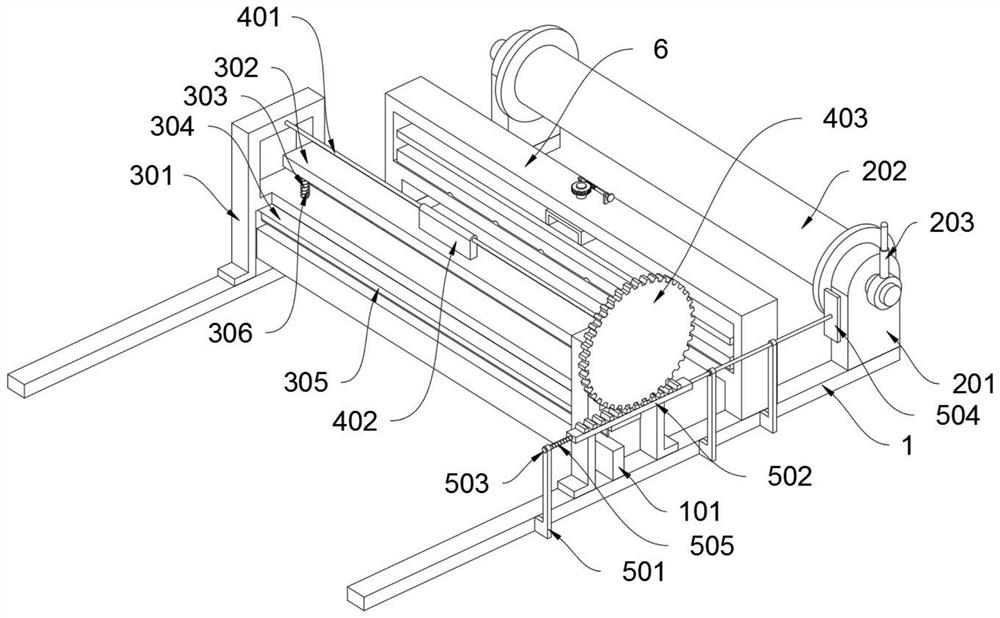

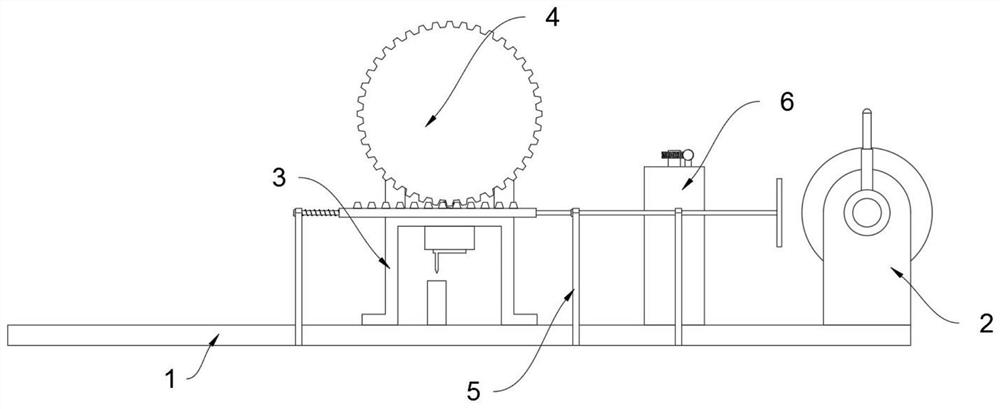

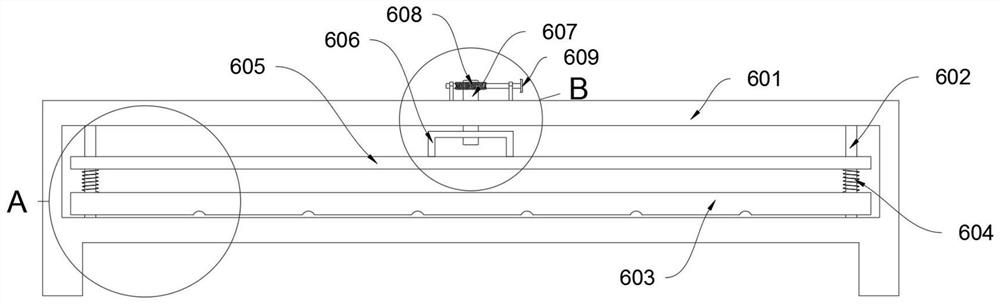

[0035] as attached figure 1 To attach Figure 8 Shown:

[0036]The present invention provides a linkage type straightening and cutting device based on winding alloy welding wire processing, including a frame body 1, a cutter seat 304 and a cutter 305; a winding structure 2 is installed on the frame body 1, and a cutting device is also installed on the frame body 1 structure 3, and the auxiliary structure 4 is installed on the cutting structure 3; the driving structure 5 is installed on the frame body 1, and the straightening structure 6 is also installed on the frame body 1; refer to as Figure 7 and Figure 8 , the cutter seat 304 includes a card slot 30401, and two card slots 30401 are symmetrically opened on the cutter seat 304; the cutter 305 includes a card connection protrusion 30501, and the cutter 305 is welded with two card connection protrusions 30501 symmetrically, and The snap-in protrusion 30501 is snap-fitted in the slot 30401, and the main part of the top, bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com