High-safety electric vehicle

A high-safety electric vehicle technology, applied in the field of electric vehicles, can solve the problems of poor safety of electric vehicles, achieve the effect of solving poor safety and reducing the risk of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

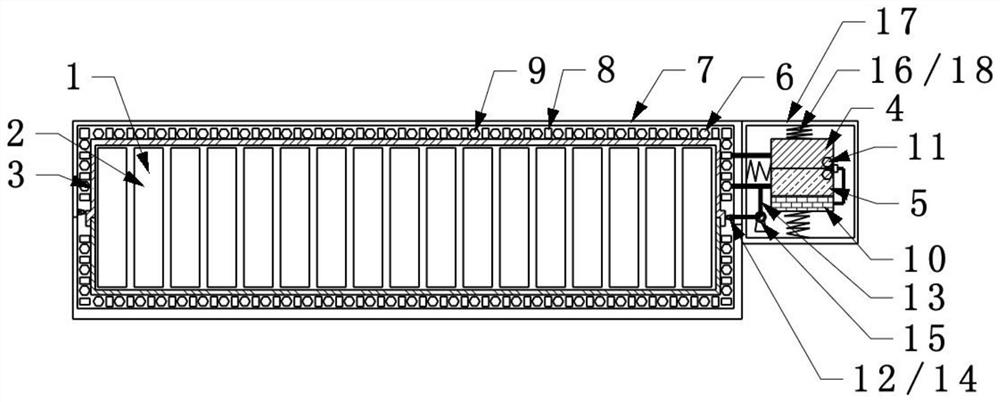

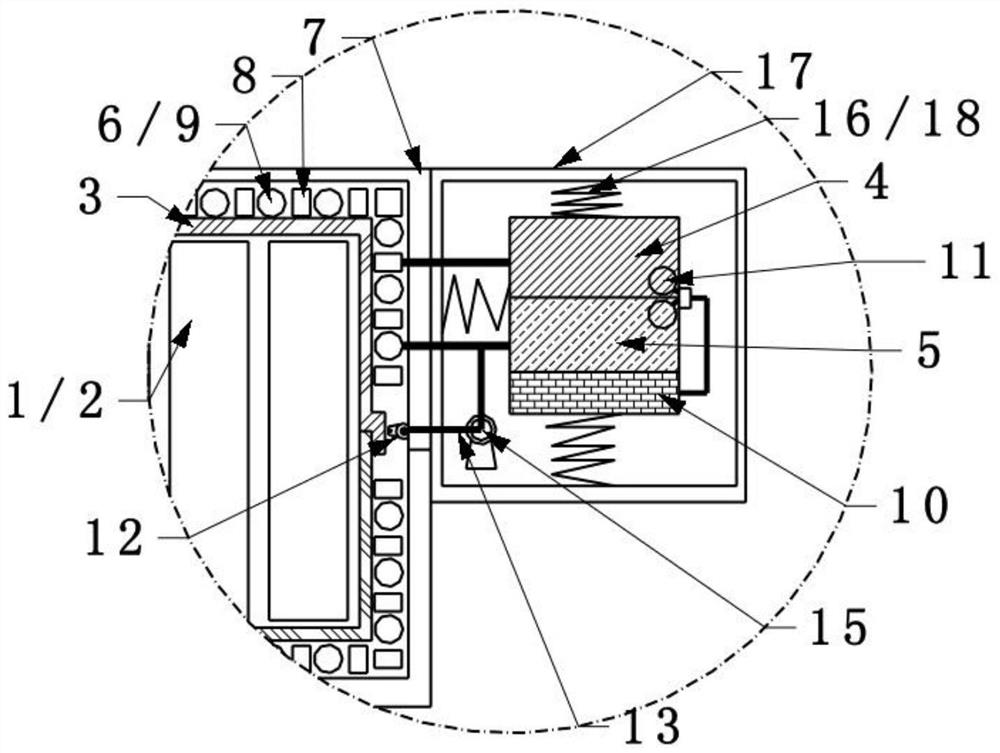

[0087] like figure 1 and figure 2 As shown, the high-safety electric vehicle includes a vehicle body, a battery pack 1 , a polyurethane chamber 4 , a carbon dioxide chamber 5 , a fragile tube 6 and a casing 7 .

[0088] The battery pack 1 includes a battery unit 2 and a battery pack case 3. There are multiple battery units 2, all of which are positioned inside the battery pack case 3 to provide power for the operation of the vehicle.

[0089] The inside of the polyurethane bin 4 is filled with flame retardant polyurethane; the flame retardant polyurethane is a polyurethane foam caulking agent added with a flame retardant; the flame retardant is an organic flame retardant or an inorganic flame retardant; The pressure inside the polyurethane chamber 4 can be 5-6 kgf / cm2, and the polyurethane chamber 4 is positioned on the vehicle.

[0090] The described carbon dioxide storehouse 5 is filled with liquid carbon dioxide.

[0091] The casing 7 is set on the battery casing 3; the...

Embodiment 2

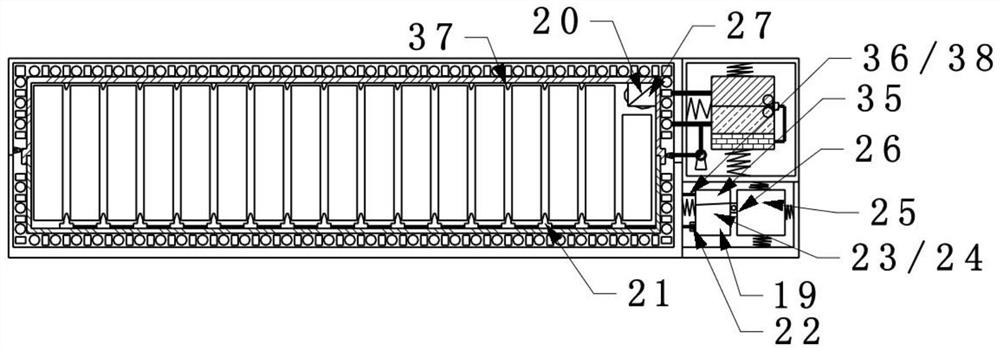

[0100] In order to further improve the safety of the electric vehicle and reduce the fire risk of the battery pack 1 , this embodiment adds a gap filling component 19 on the basis of the first embodiment.

[0101] like figure 1 and figure 2 As shown, the gap filling assembly 19 includes a temperature sensor 20, a control assembly 39, a filling hose, a filling nozzle 21, a filling valve body 22 and a filling chamber 23; the temperature sensor 20 is positioned in the battery pack casing 3, used to detect the temperature of the battery unit 2; the temperature sensor 20 is electrically connected to the independent power supply 10, and is connected to the signal of the control assembly 39; the control assembly 39 is used to control the valve body ( The action of filling the valve body 22) can be a logic controller, which is a prior art, and will not be described in detail here; the number of the filling nozzles 21 is multiple, all fixed on the battery pack casing 3, spatially Lo...

Embodiment 3

[0105] Considering that the gap filling assembly 19 in the second embodiment is in operation (filling up the gap between the battery cells 2), the amount of flame-retardant polyurethane that needs to be sprayed will be different because of whether the actual battery pack case 3 is damaged (the battery pack case 3 After the damage, the flame-retardant polyurethane ejected by the filling nozzle 21 may be extruded from the crack, and the demand for the flame-retardant polyurethane is larger than that of the battery pack shell 3 without damage 2), and it is also related to whether the battery unit 2 has caught fire ( The fire temperature is too high, which affects the foaming of flame-retardant polyurethane); in line with the principle of practicality and economy, this embodiment has made the following improvements on the basis of embodiment two:

[0106] Such as Figure 5 As shown, the filling bin 23 includes a primary filling bin 24 and a secondary filling bin 25; the primary fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com