Automatic feeding system for knitted socks and corsets

A technology of automatic material feeding and sock waist, which is applied in packaging and other directions, can solve the problems of high labor intensity, poor packaging quality, and low positioning accuracy, and achieve the goal of improving packaging efficiency and quality, improving accuracy, and reducing production and operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

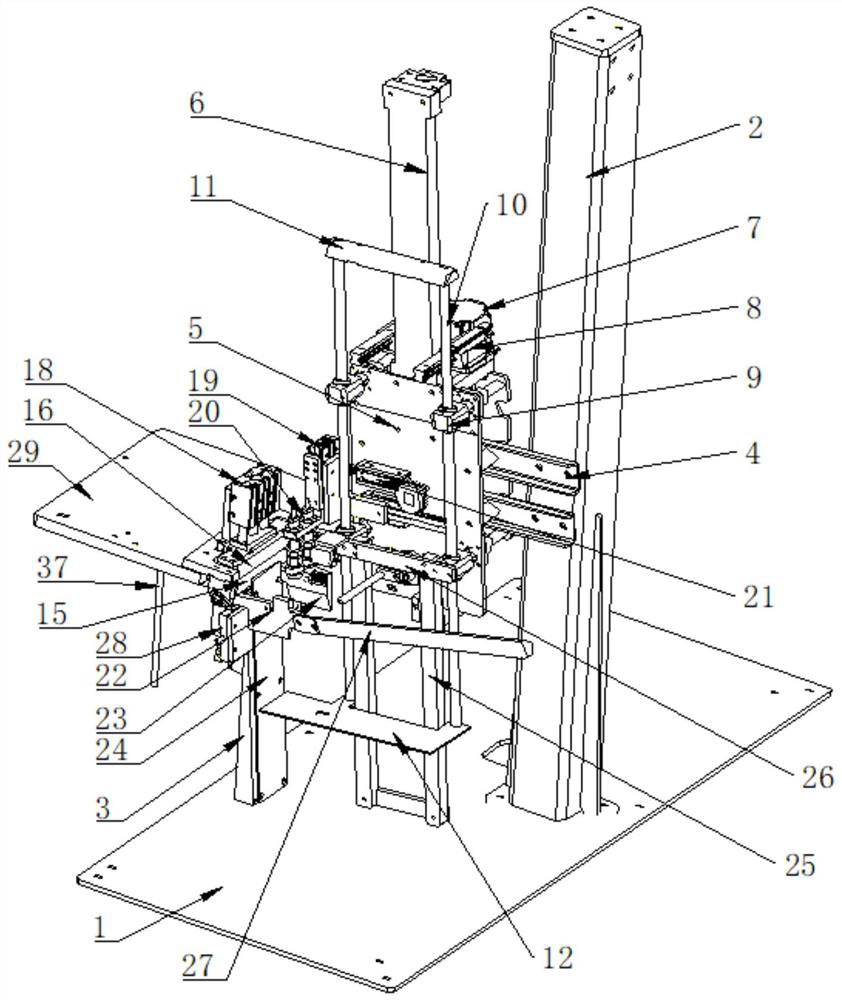

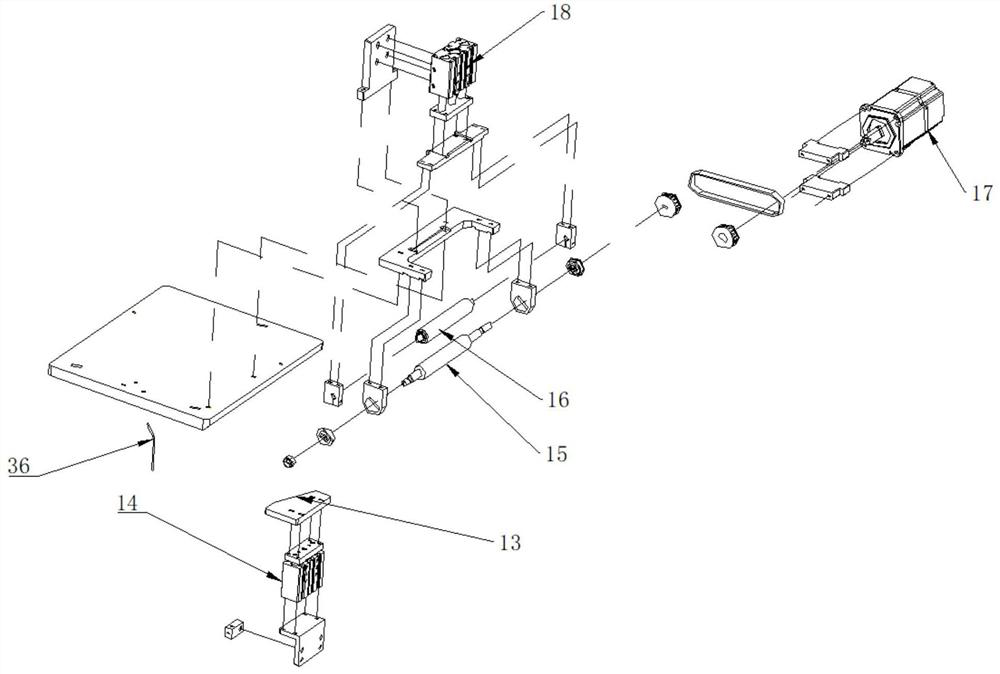

[0022] The present invention is further described and understood by non-limiting examples below.

[0023] Such as Figure 1-4 As shown, the present invention is an automatic feeding system for knitting socks girdle, which is arranged between the installation base 1 and the bracket 2, and includes the support seat 3 of the transport assembly, the lifting assembly of the silo, the suction nozzle assembly, and the support seat 3 of the transport assembly. The handling assembly mounting base 29, the handling assembly above;

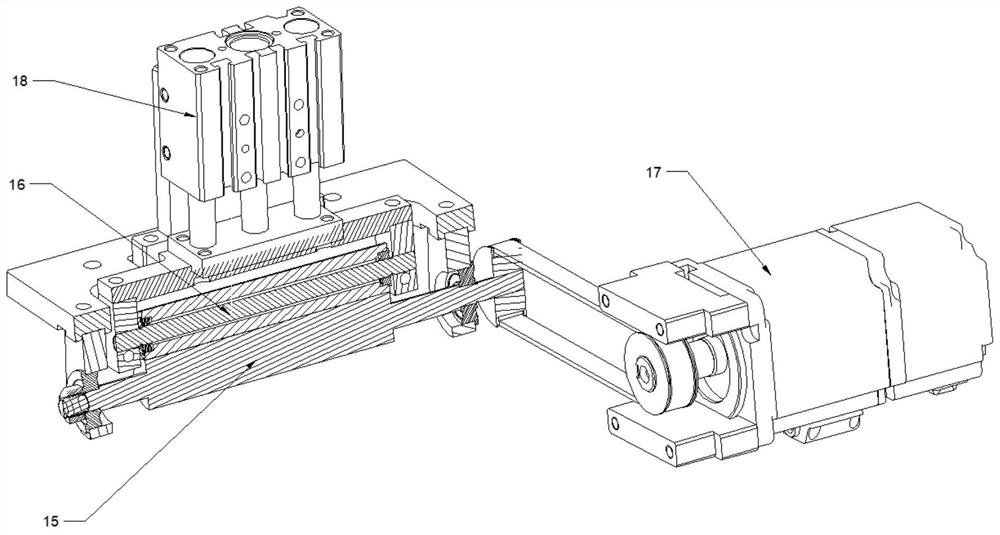

[0024] The silo lifting assembly includes a silo assembly mounting plate 5, two sets of bearing mounts 9 fixed on one side of the silo assembly mounting plate 5, and a ball screw drive assembly 6 vertically fixed on the other side of the silo assembly mounting plate 5 , the lifting servo motor 7 used to drive the movement of the ball screw transmission assembly 6, two sets of directional slider guide rail assemblies 8 fixedly installed on the sliding seat of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com