Reciprocating traverse-movement type yarn guiding and forming device and application thereof

A forming device and yarn guiding technology, which is used in transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problem that the speed and position of the forward and reverse of the motor cannot be accurately controlled, the quality of the yarn is unstable, and the motor High power consumption and other issues, to achieve the requirements of reducing power consumption and heat dissipation, stable product quality, and reduce the effect of carrying load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

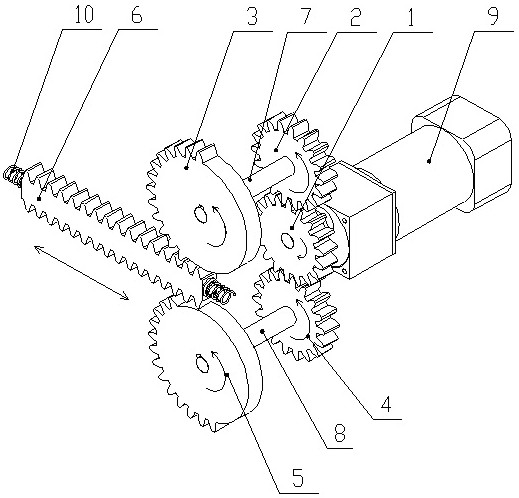

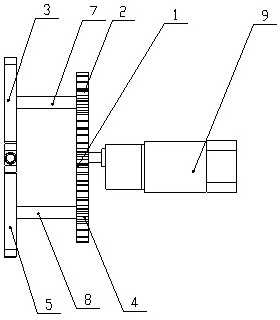

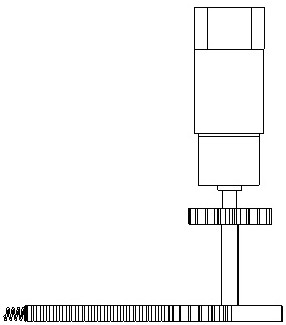

[0021] see Figure 1-Figure 4 , figure 1 A schematic diagram of the structure of a reciprocating and traversing yarn guiding forming device is drawn. As shown in the figure, a reciprocating traverse guide forming device of the present invention includes a main transmission gear 1, a first driven wheel 2, an upper gap half tooth surface gear 3, a second driven wheel 4, a lower gap half tooth surface Gear 5, reciprocating traverse rack 6 and speed regulating motor 9.

[0022] The main transmission gear 1 is connected with the speed regulating motor 9, and the top of the main transmission gear 1 meshes with the first driven wheel 2, and the first driven wheel 2 is connected with the upper gap half-tooth gear through the first connecting rod 7 3 connection; the bottom of the main transmission gear 1 meshes with the second driven wheel 4, and the second driven wheel 4 is connected with the lower gap half-tooth gear 5 through the second connecting rod 8.

[0023] A reciprocating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com