High-fluidity black flame-retardant reinforced polyethylene glycol terephthalate composition and preparation method thereof

A polyethylene terephthalate, high-fluidity technology, applied in the field of engineering plastics, can solve problems such as fluidity reduction, under-injection, and insufficient fluidity, so as to improve material fluidity, clarity and contrast , Improve the effect of laser marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

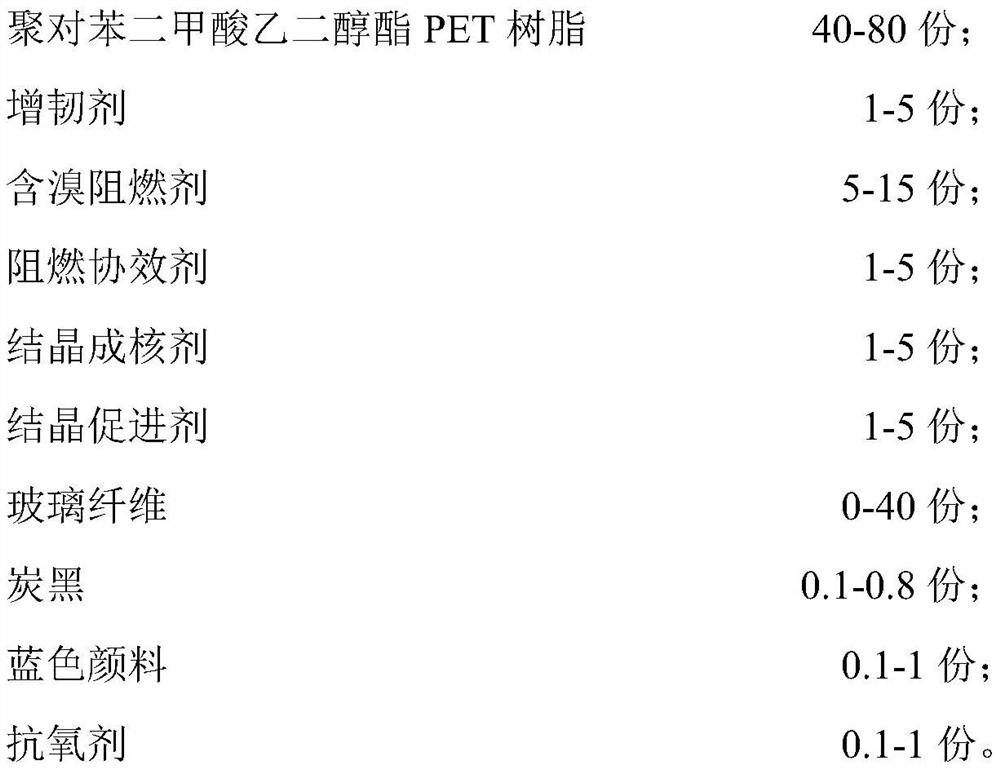

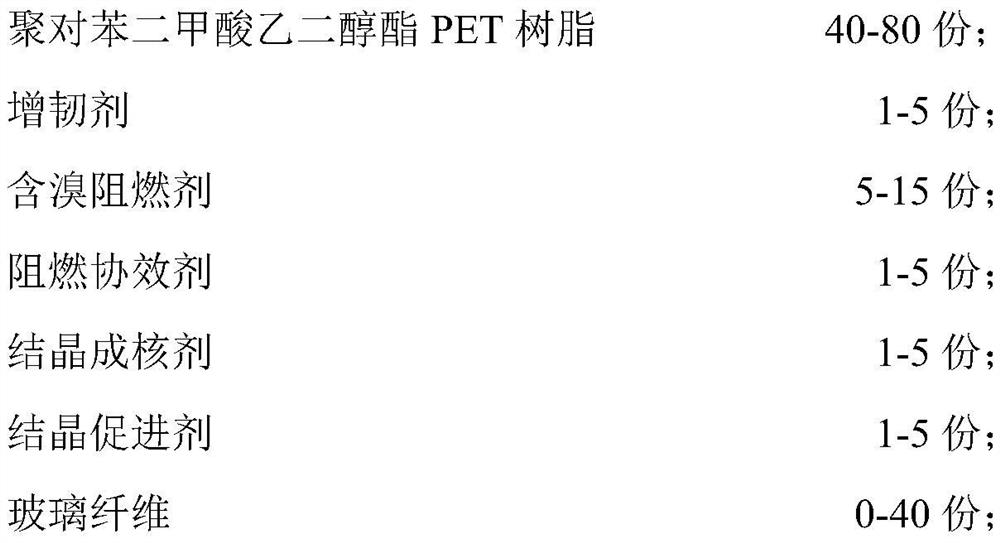

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

[0023] The raw material selection of embodiment and comparative example:

[0024] PET resin: the intrinsic viscosity is 0.5dl / g, the brand is CR-7702, China Resources Packaging Materials Co., Ltd.;

[0025] The intrinsic viscosity is 0.68dl / g, the grade is FG600, and the Engineering Plastics Factory of Sinopec Asset Management Co., Ltd. Yizheng Branch;

[0026] The intrinsic viscosity is 0.8dl / g, the grade is BG80, and it was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com