Emergency treatment method for grout explosion in the bottom connecting cavity of precast concrete shear wall

A prefabricated concrete and emergency treatment technology, which is applied in the treatment of building materials, walls, buildings, etc., can solve the problems of troublesome treatment methods, expensive prices, and long time-consuming, so as to achieve controllable costs, improve work efficiency and emergency response. ability, consider the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

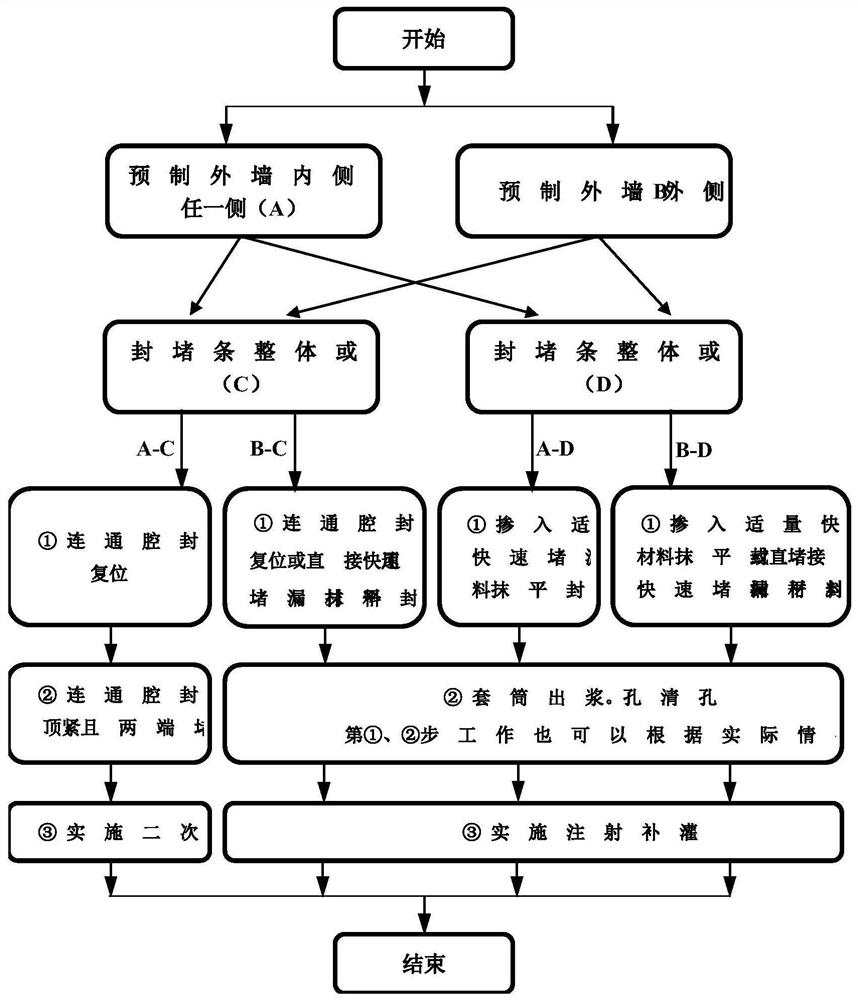

[0031] See attached figure 1 , combined with the attached Figure 2-4 , the sealing strip of the connecting cavity at the bottom of one side of the prefabricated inner wall is partially disengaged, that is, when it is in state A and state C at the same time.

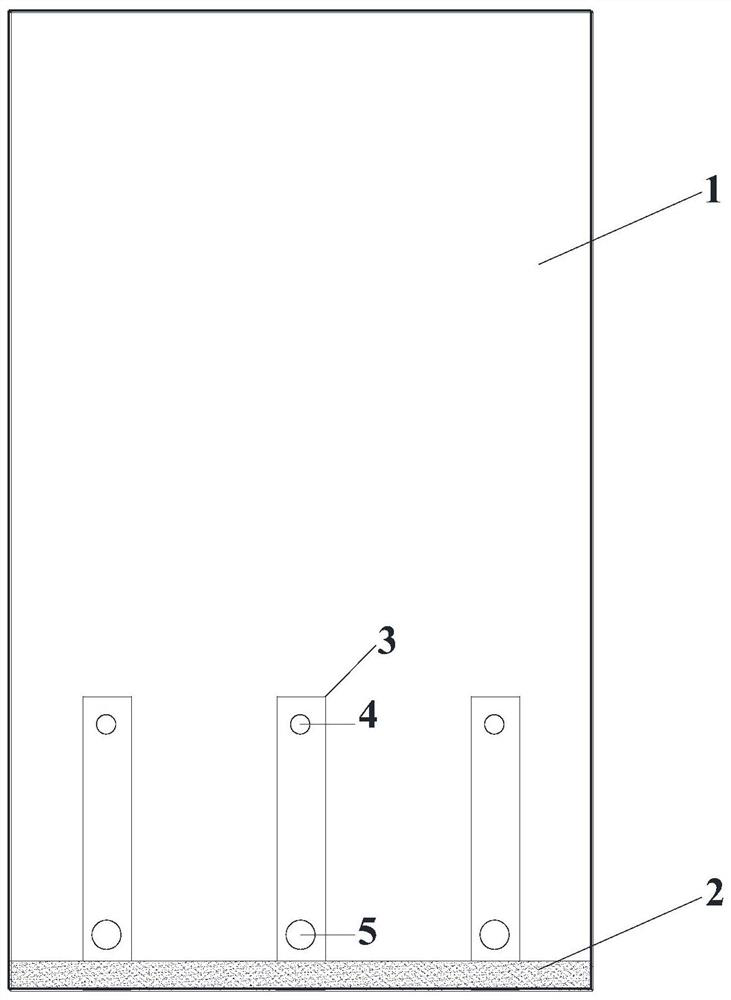

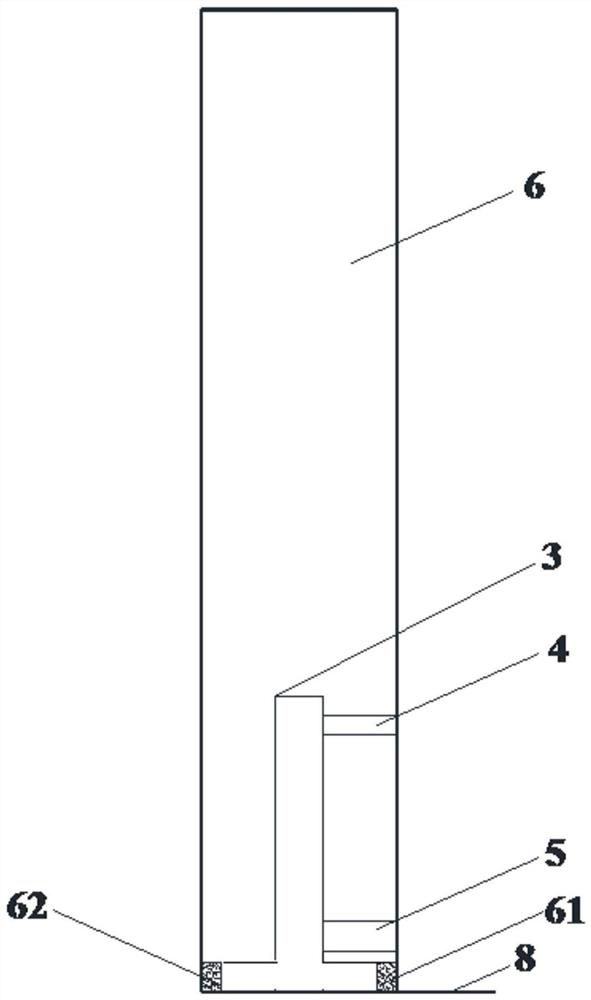

[0032] see figure 2 and 4 , a precast concrete shear wall is the inner wall 7, and the length of the connecting cavity sealing strips 71 and 72 at the bottom is 1.1m. Three sleeves 3 are arranged in this length range, and the connecting cavity is grouted in the middle sleeve grouting hole 5 . During the grouting process, there is an overall disengagement and explosion of grouting in the middle range of about 0.3m in the middle range of the connecting cavity sealing strip 72 on the back side of the grouting hole. Emergency treatment is now carried out for it. The specific steps are as follows:

[0033] ① Reset the disconnected connecting chamber sealing strip to realize effective connection with the part that has not...

Embodiment 2

[0037] Simultaneously combined with Figure 2-4 , the sealing strip of the connecting cavity at the bottom of the outer side of the prefabricated exterior wall is partially broken and falls off, that is, when it is in state B and state D at the same time.

[0038] see figure 2 and 3 , a precast concrete shear wall is the outer wall 6, and the length of the connecting cavity sealing strips 61 and 62 at the bottom is 1.0m. Three sets of 3 are arranged in this length range, and the connecting cavity is grouted in the middle sleeve grouting hole 5. During the grouting process, the outer connecting cavity sealing strip 62 was broken and fell in the middle range of about 0.26m in length. Emergency treatment is now carried out. The specific steps are as follows:

[0039] ①Because the broken sealing strip of the connecting cavity has fallen off, directly use the rapid plugging material to smooth and seal the 0.26m long slurry explosion area.

[0040] ②Before the slurry bursts, all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com