A garbage truck weighing device with automatic angle correction

A technology of weighing device and garbage truck, which is applied in the direction of measuring device, detailed information of weighing device, weighing, etc., can solve problems such as overloading and accidents, and achieve the effect of avoiding detection errors and facilitating weight detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

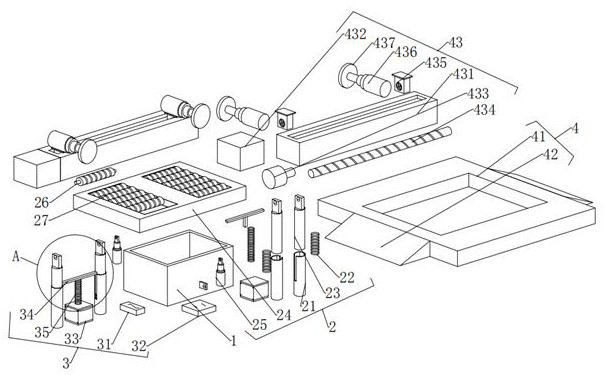

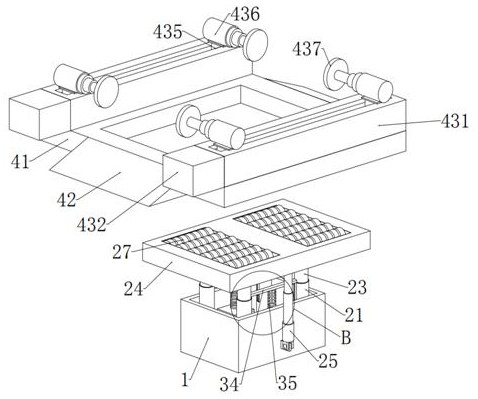

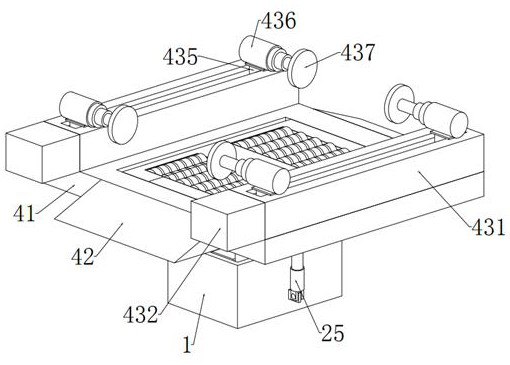

[0049] Embodiment: according to specification Figure 1-5 It can be seen that, firstly, through the auxiliary correction structure 4 running plate 42, the car body can be conveniently driven to the weighing platform 24 in the load-bearing structure 2 at the center of the outer frame 41, and then controlled by the wireless module 32 and the remote connection. Drive the device through the main control module 31;

[0050] Secondly, when the car body moves to the weighing platform 24, the wheels are positioned on the steel wheel 27, and then the weighing platform 24 descends after being stressed, so that the support rod 23 descends in the position-limiting tube 21, and then squeezes the first spring 22. Buffering is performed, and at the same time, the connecting rod 34 in the detection structure 3 is connected to the transmission and lowered at the same time, and the second spring 35 is used to squeeze the gravity sensor 33 for detection, so that the data is synchronized to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com