Test equipment for pilotless automobile

A technology for unmanned vehicles and test equipment, applied in the field of unmanned vehicle test equipment, can solve problems such as loose rollers, inaccurate data, irregular vibration, etc., and achieve the goals of avoiding wear and tear, facilitating maintenance, and accelerating replacement speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

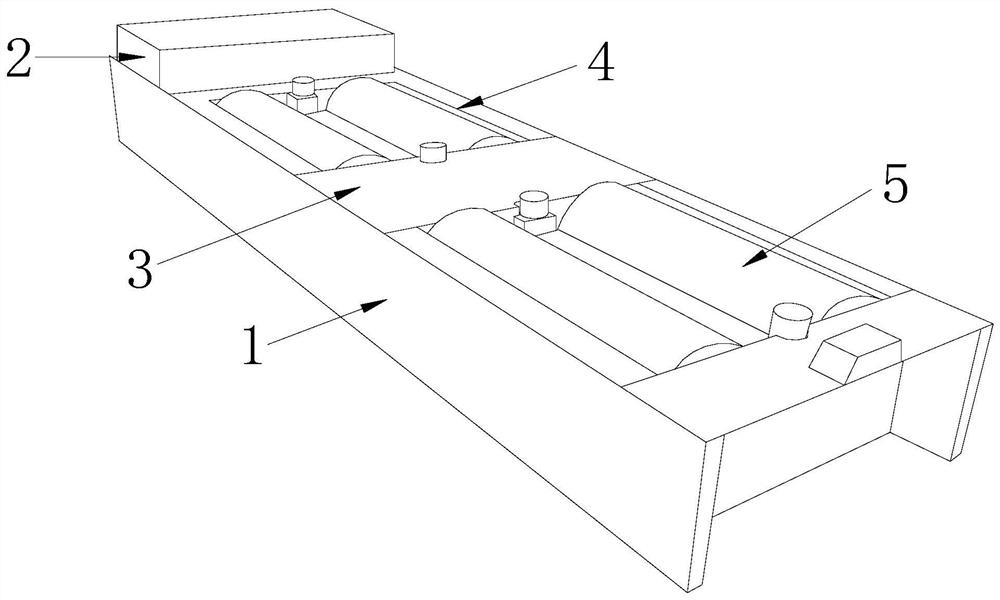

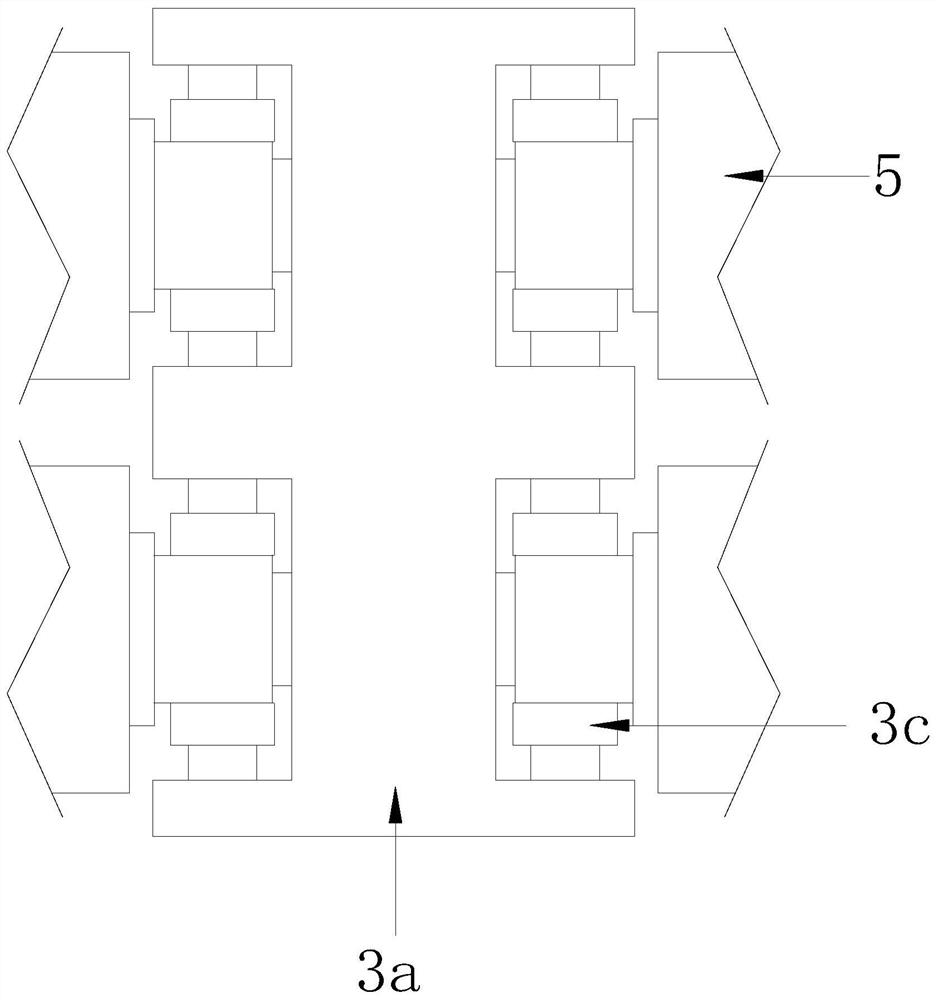

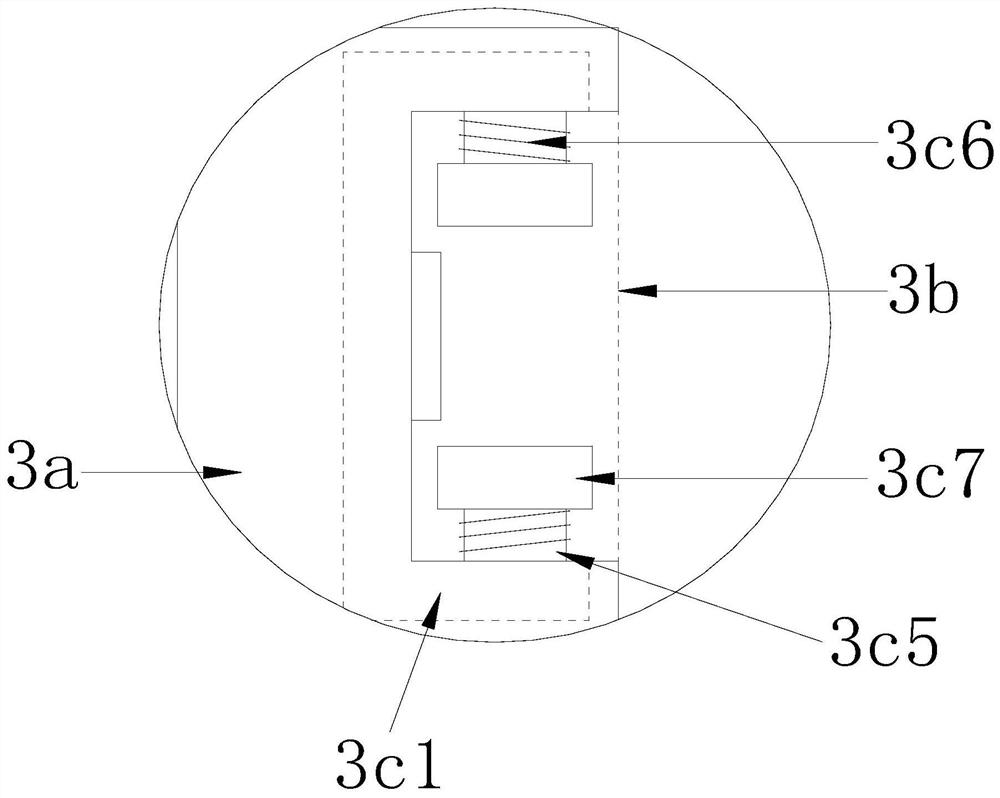

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 Shown, the present invention provides a kind of technical scheme of the test equipment of driverless car:

[0031] Such as Figure 1-Figure 3 As shown, a test equipment for unmanned vehicles, its structure includes a base 1, a power frame 2, a shaft protection device 3, an empty frame 4, and a roller 5, and the power frame 2 is arranged on the left side of the base 1 and connected, The shaft protection device 3 is arranged in the middle of the base 1 and is connected to each other. There are two empty frames 4 which are respectively arranged inside the base 1 with the shaft protection device 3 as the center line. The rollers 5 are in the form of two group and respectively installed inside the empty frame 4, the roller 5 is connected to the contact end of the shaft protection device 3 by fitting and connecting. A total of four openings 3b are installed on the left and right sides of the f...

no. 2 example

[0040] Such as Image 6 Shown, the present invention provides a kind of technical scheme of the test equipment of driverless car:

[0041] Such as Image 6 Shown, a kind of test equipment of unmanned automobile, its structure comprises that said squeeze member 3c4 comprises fixed plate 3c41, pressure push ball 3c42, return spring 3c43, sticking plate 3c44, friction bar 3c45, described fixed plate 3c41 and The conveying plate 3c3 is connected through and connected, and the pressing and pushing ball 3c42 is arranged in the middle of the fixed plate 3c41 and cooperates with each other. It is connected to the front surface of the push ball 3c42, and the friction strips 3c45 are provided with two and are symmetrically installed on the front surface of the sticking plate 3c44 respectively, which is beneficial to cooperate with the cylinder 5 when there is an irregular vibration situation. 5 Do timely suppression of vibration for easy maintenance.

[0042] Such as Image 6 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com