High-precision as-fired coal automatic rotary sampling equipment

A technology of automatic rotation and sampling equipment, applied in the direction of sampling devices, etc., can solve the problems of inaccurate data, low adjustability, and low precision, and achieve the effects of accurate detection results, wide sampling range, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

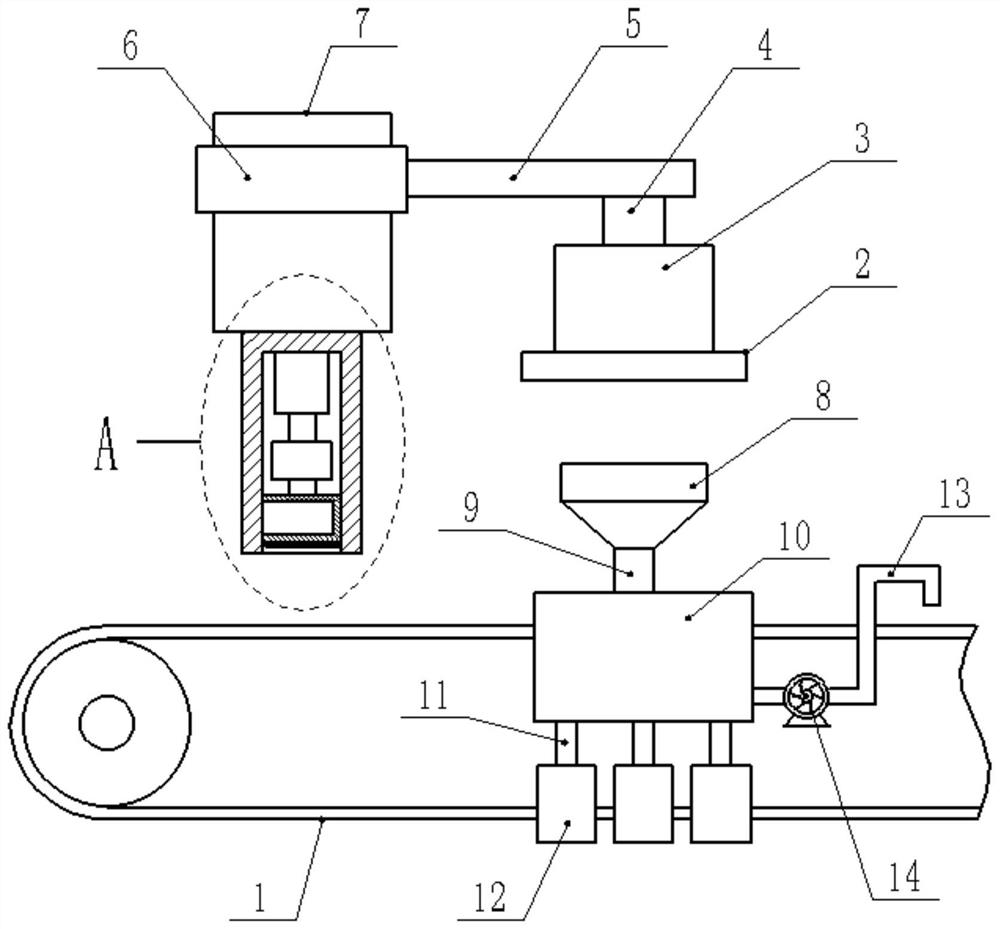

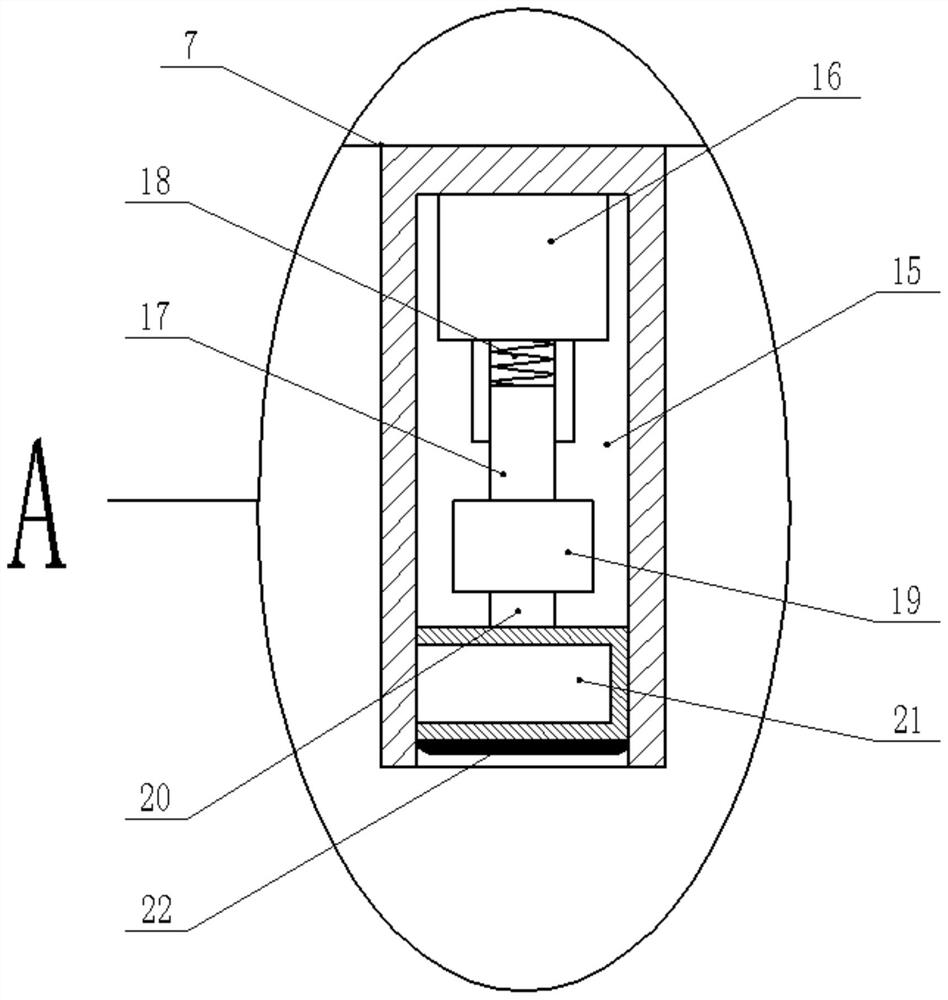

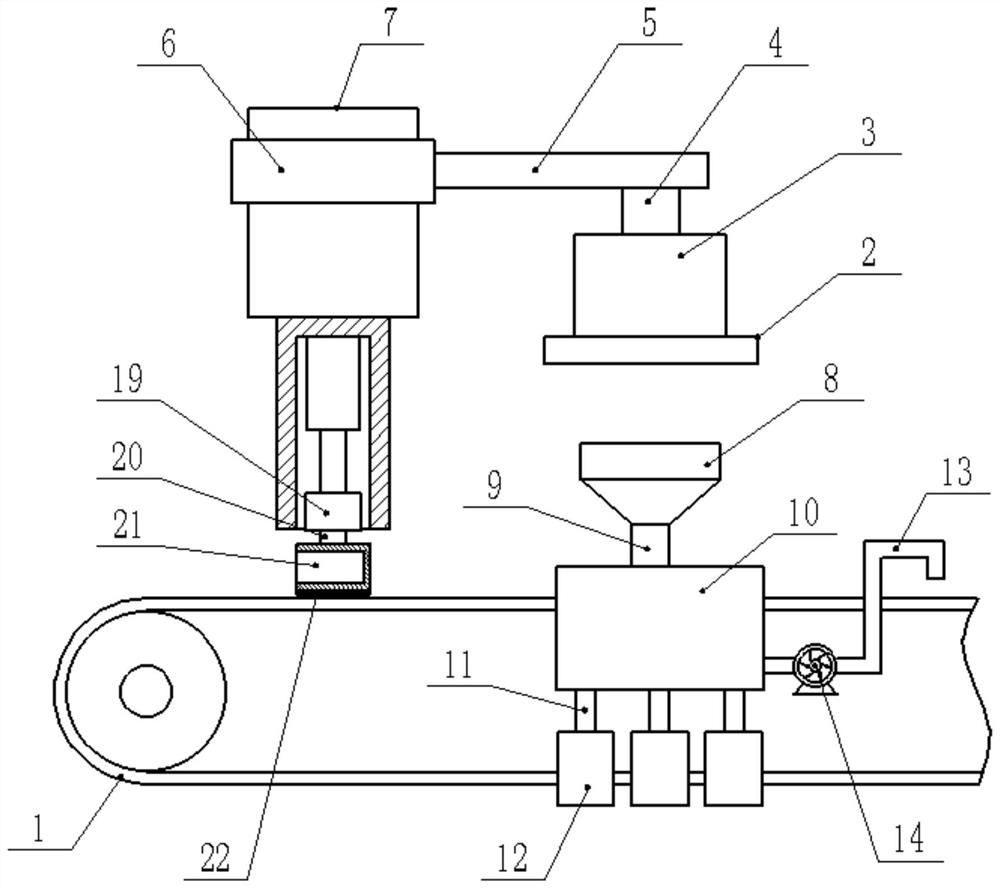

[0020] see Figure 1-5 , a high-precision automatic rotary sampling device for furnace coal, comprising a feeding mechanism 1, a first motor 3, a telescopic cylinder 7, a sampling storage box 12, an electric telescopic rod 16, a second motor 19 and a sampling head 21; the feeding mechanism 1 is a conveyor belt structure driven by a driving motor, which is used to transport coal into the furnace. A fixed plate 2 is arranged above the feeding mechanism 1. The fixed plate 2 is fixedly installed above the feeding mechanism 1 and keeps a certain distance from the feeding mechanism 1. A first motor 3 is installed above the fixed plate 2, a first rotating shaft 4 is installed above the first motor 3, a first connecting rod 5 is installed above the first rotating shaft 4, and the first connecting rod 5 is far away from the first rotating shaft 4. A fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com