Plate surface wear resistance testing device for building indoor decoration

A technology for interior decoration and testing equipment, applied in the direction of testing wear resistance, etc., can solve the problems of affecting test efficiency, troublesome operation, inconvenient use, etc., and achieve the effects of simple and fast operation, improved use efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

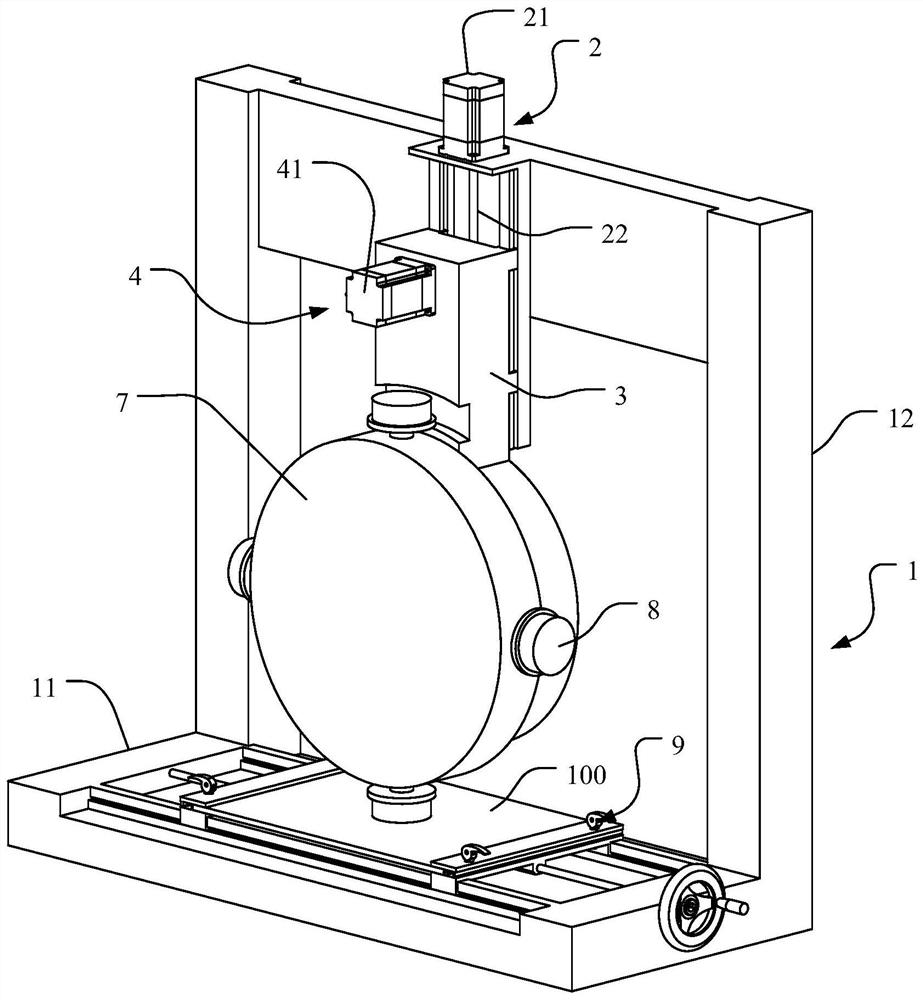

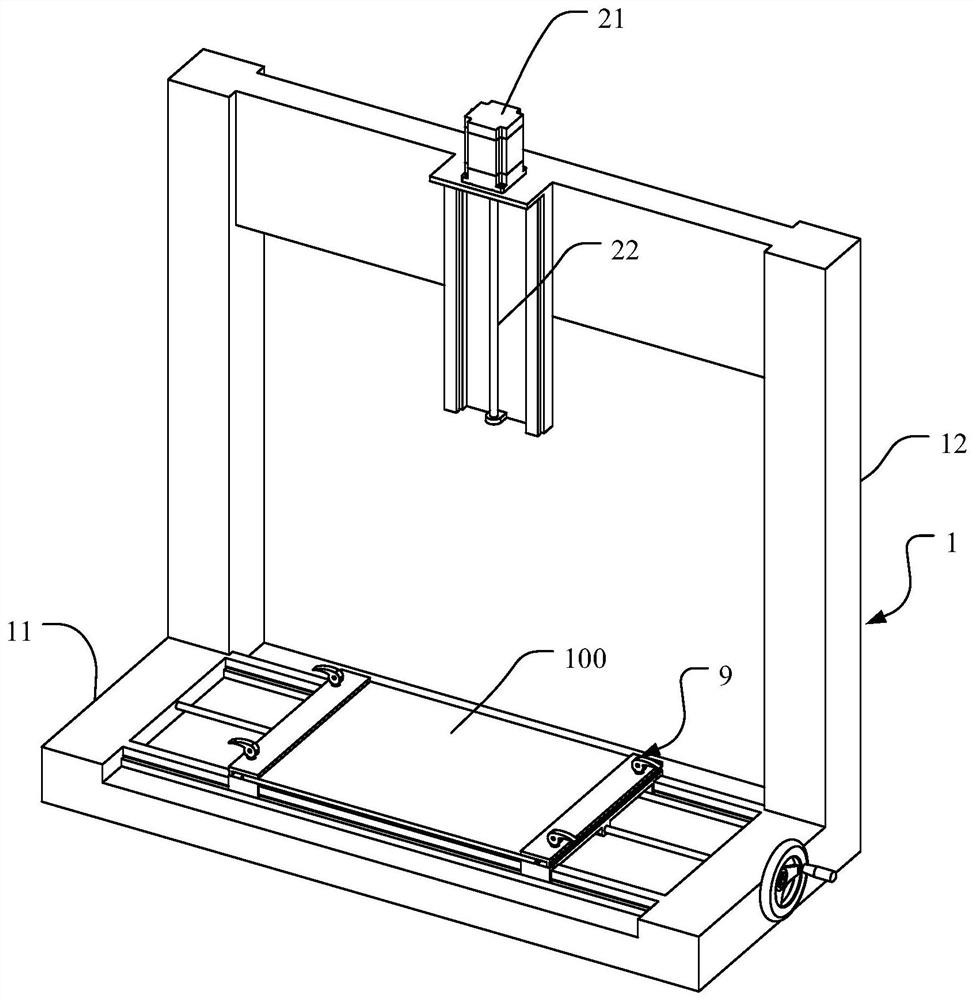

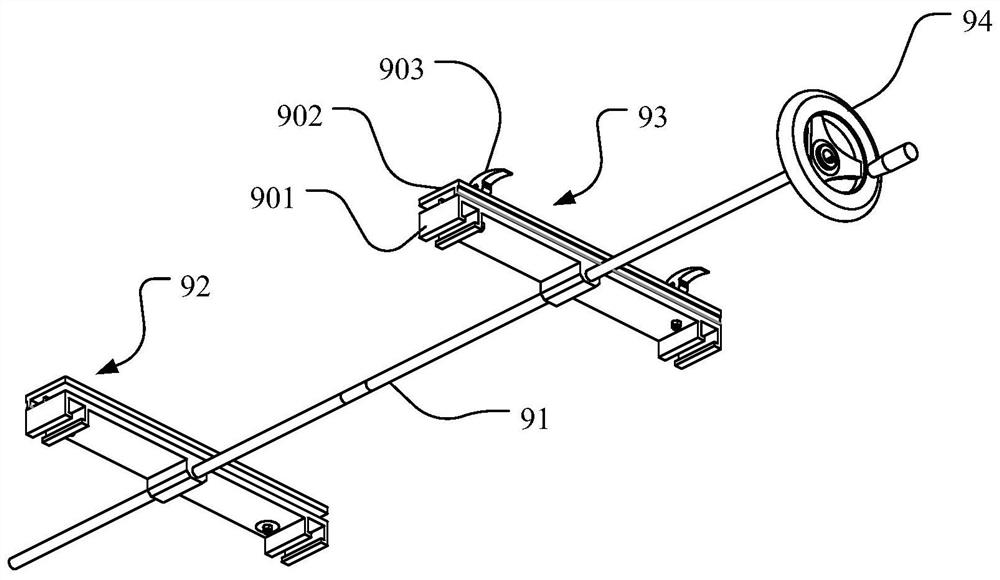

[0032] see Figure 1 to Figure 8 , in this embodiment, the device for testing the wear resistance of the plate surface for building interior decoration includes a support frame 1, a lifting drive part 2, a lifting assembly 3, a main motion drive part 4, a main motion intermediate transmission part 5, and a grinding head conversion The driving part 6, the grinding head installation turntable 7, a plurality of wear-resistant test grinding head assemblies 8, and the clamping assembly 9, the lifting driving part 2 is arranged on the support frame 1, the lifting component 3 is connected to the lifting driving part 2, and the lifting The component 3 can move up and down under the drive of the lifting drive part 2. The main motion drive part 4 is set on the lifting component 3, the main motion intermediate transmission part 5 is rotatably set on the lifting component 3, and the grinding head conversion drive part 6 is set on the lifting component 3. Assembly 3 is used to drive the ro...

no. 2 example

[0051] In this embodiment, the difference from the first embodiment is:

[0052] In this embodiment, a tilting platform is provided on the base plate 11, the tilting platform is rotatably arranged on the base plate 11, the rotation axis of the tilting platform is set perpendicular to the vertical plate 12, and the clamping assembly 9 is arranged on the tilting platform , the clamping assembly 9 can tilt along with the translation platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com