Distributor and grain imperfect grain scanning detection system with same

A technology of scanning detection and dispenser, which is applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve the problems of high feeding requirements, low detection efficiency, and inability to meet the requirements of fast, efficient, and continuous detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

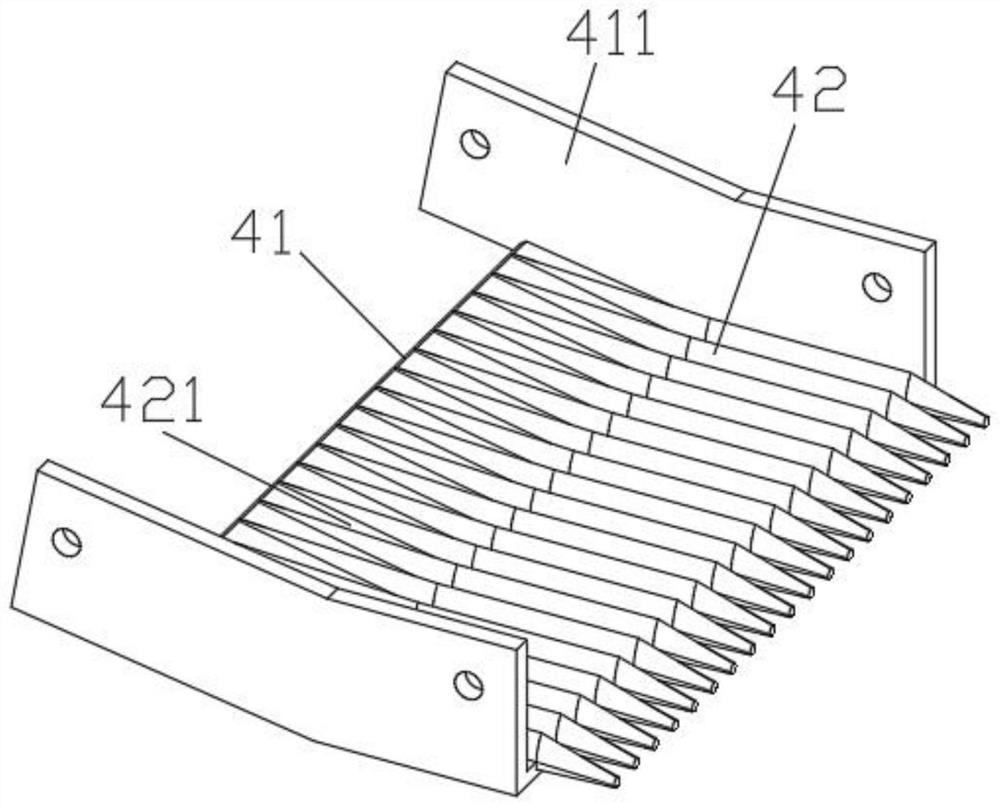

[0027] like figure 1 As shown, the distributor of this embodiment includes a horizontal material plate 41 and a plurality of comb bars 42, and the two sides of the material plate 41 are respectively provided with vertically upward and parallel baffle plates 411, and the above-mentioned comb bars 42 Extending towards both ends of the above-mentioned material plate 41, a plurality of the above-mentioned comb tooth bars 42 are all fixed on the upper end of the above-mentioned material plate 41, and are arranged in multiple rows side by side between the above-mentioned baffle plates 411 on both sides. A distributing groove 421 for accommodating single-grain grains is defined between the racks 42 .

[0028] In this embodiment, a plurality of side-by-side distribution troughs are formed between the distributors, which can orderly divide the materials into multiple columns for transportation, which is beneficial to the operation of the next stage of the process.

[0029] Preferably,...

Embodiment 2

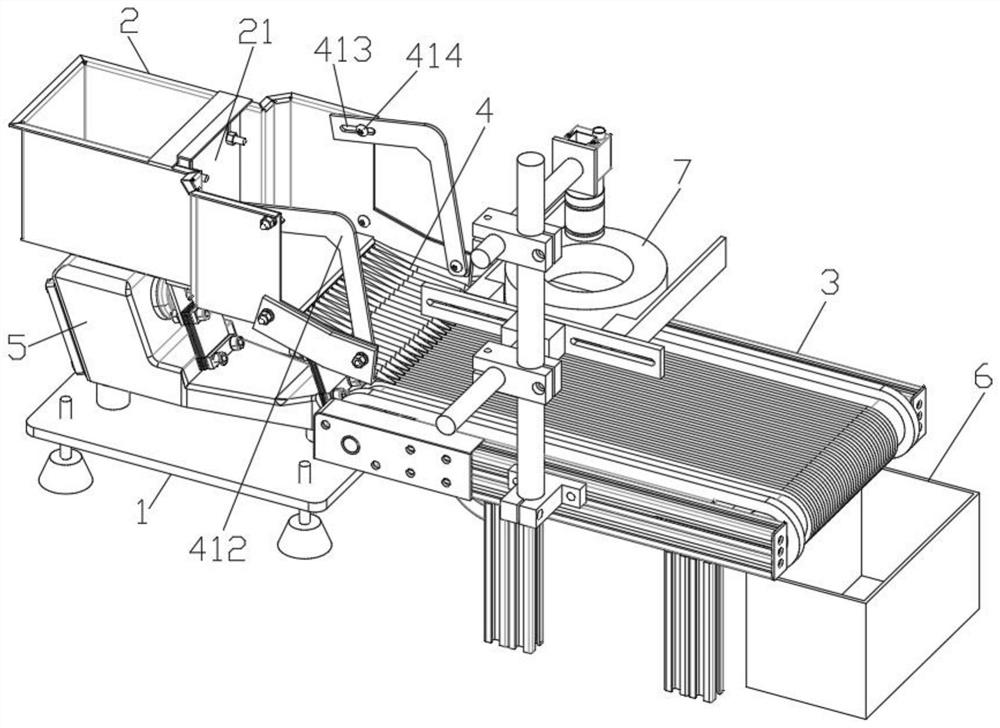

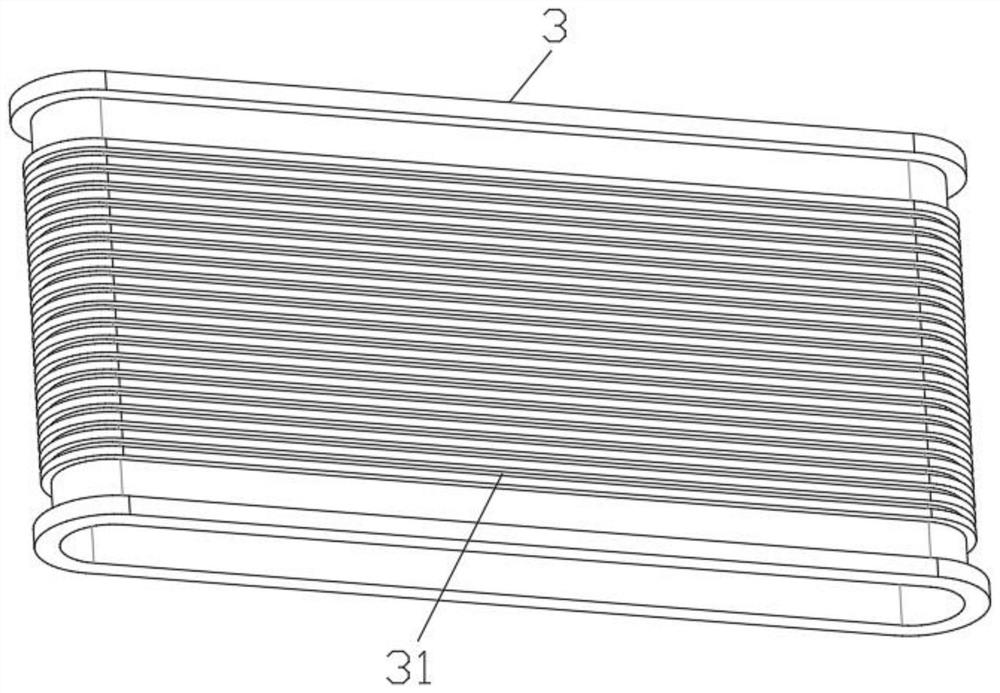

[0032] like figure 2 and 3 As shown, the grain imperfect grain scanning detection system of this embodiment includes a support platform 1, a lower hopper 2, a belt conveyor 3, a scanner 7, an image display terminal and the above-mentioned material distribution system according to any one of claims 1 to 3. Device 4, the above-mentioned belt conveyor 3 is arranged on one side of the above-mentioned support platform 1, and its conveying surface is provided with a plurality of running troughs 31 across its conveying surface along the conveying direction of its conveying surface. The distribution troughs 421 correspond one by one, the above-mentioned lower hopper 2 is installed above the above-mentioned support platform 1, one end of the above-mentioned distributor 4 is connected to the discharge port of the above-mentioned lower hopper 2, and the other end is placed on the conveying surface of the above-mentioned belt conveyor 3 On the feeding end, and the distributing chute 421...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com