Stably-used low-speed large-torque drive motor

A driving motor, high torque technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problem of low stability in use, and achieve the effect of ensuring stability, ensuring position stability, and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-6 The application is described in further detail.

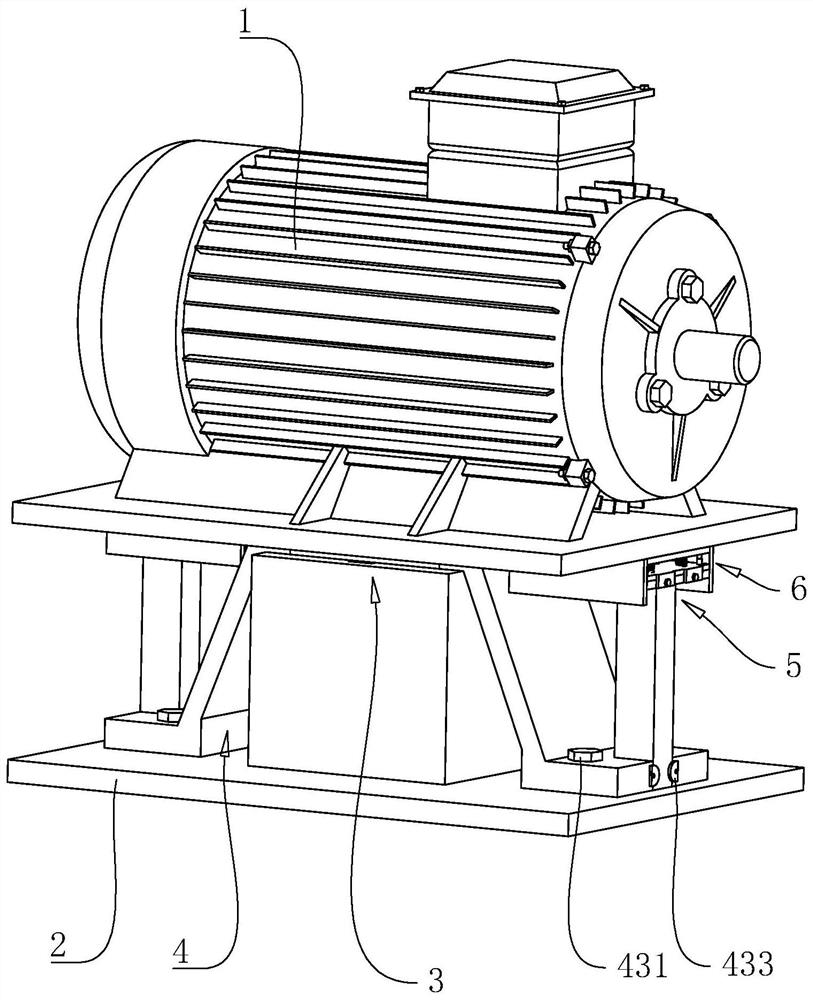

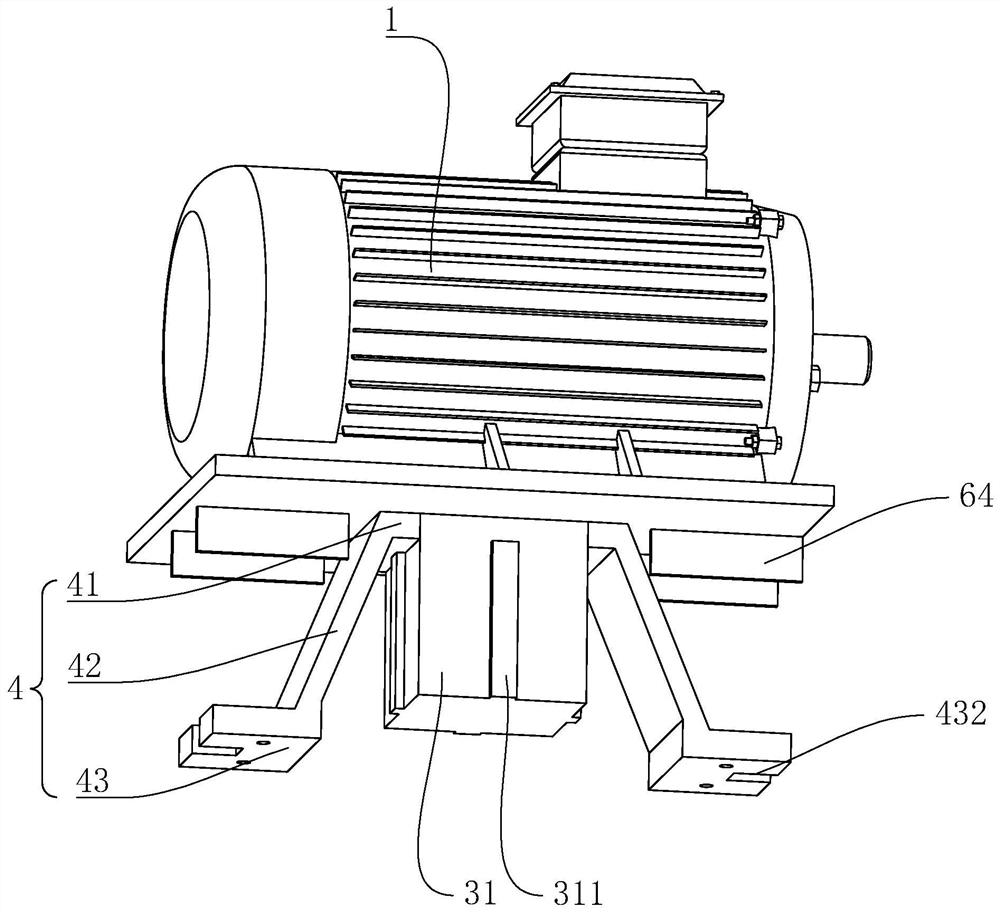

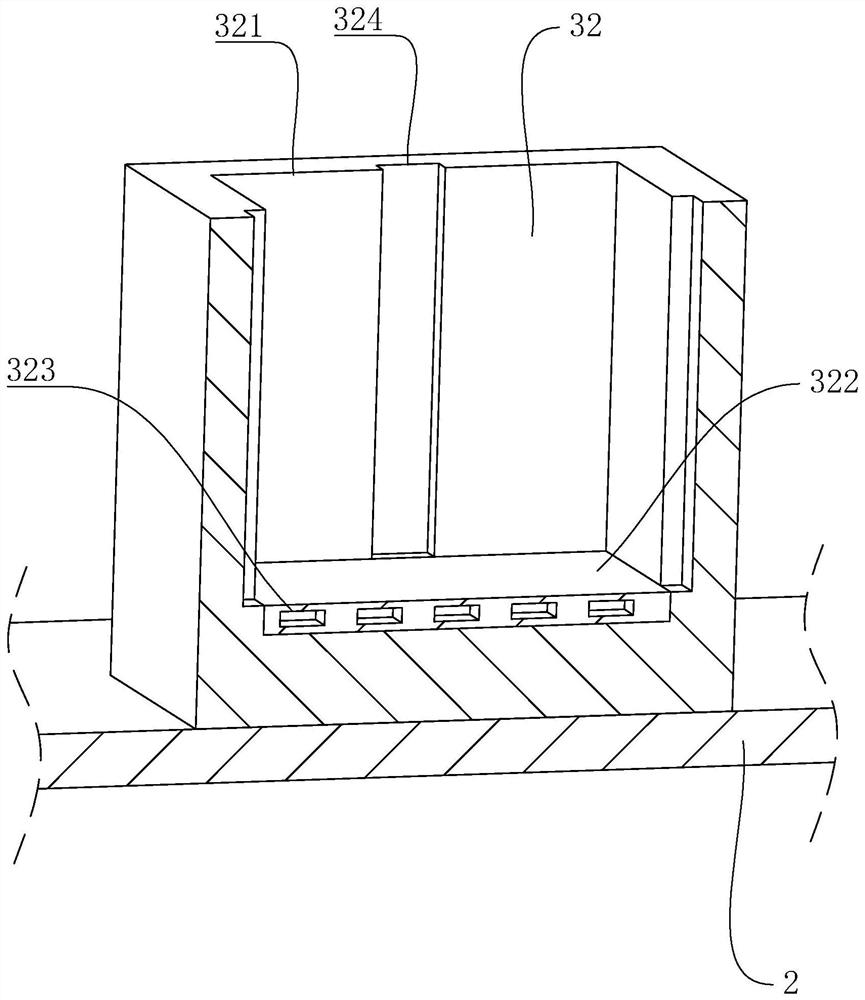

[0036] The embodiment of the present application discloses a stable low-speed high-torque drive motor. refer to figure 1 , including a body 1 and a mounting plate 2. The mounting plate 2 is located under the body 1. After the body 1 is fixedly connected to the mounting plate 2, the operator can fix the mounting plate 2 to the equipment through bolts, so that the body 1 can run stably on the equipment.

[0037] refer to figure 1 , the body 1 and the mounting plate 2 are jointly provided with a positioning component 3 and a supporting component 5, the positioning component 3 makes the body 1 stably positioned on the top wall of the mounting plate 2, and the supporting component 5 effectively ensures that the body 1 is positioned on the top wall of the mounting plate 2 The position stability of the body 1 is improved, and the connection strength between the body 1 and the mounting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com