An improved carbonation and greening treatment system for desert sand fixation

A treatment system, desert technology, applied in the transmission system, direct liquid fertilizer delivery system, seeding, etc., can solve the problems of low treatment efficiency, poor environmental benefits and stability, and poor treatment effect of the treatment system or equipment, so as to avoid excessive Fast evaporation, good environment and protection, and the effect of saving treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

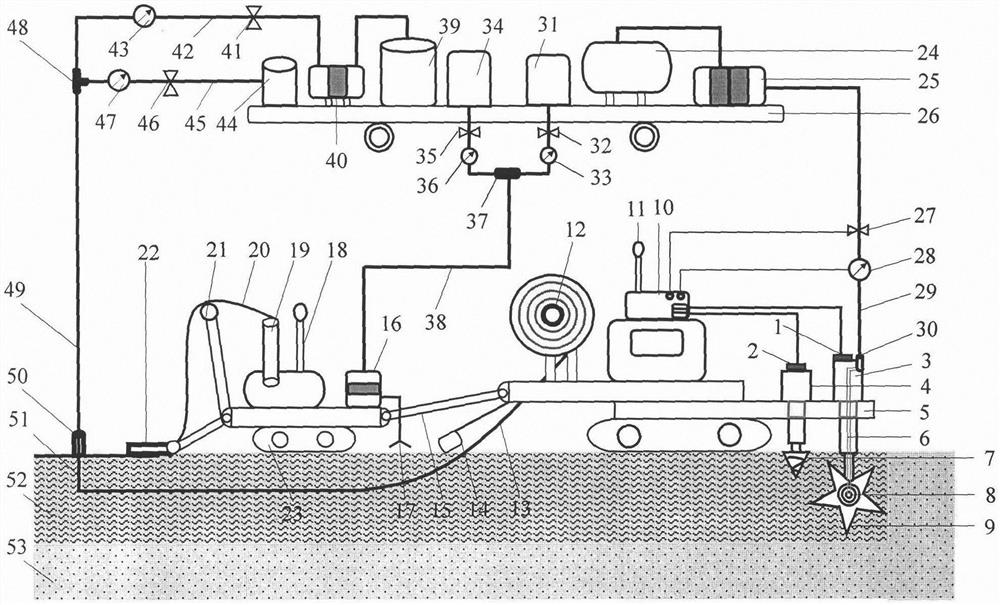

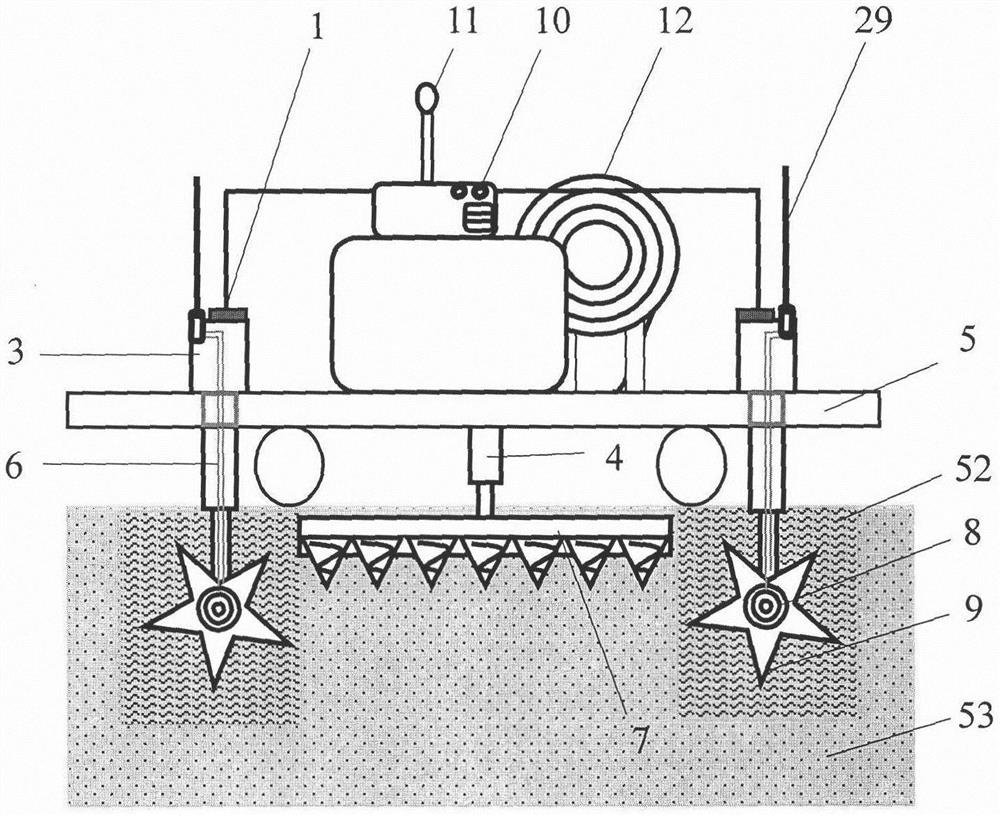

[0049] a. On the basis of the steps of the above method, if the thickness of the desert soil layer is greater than 3.0m, the content of fine sand is 85%, and the moisture content is less than 4%, then the mixture of magnesium oxide and slag is selected as the main curing agent, and the content of magnesium oxide powder accounts for 80% of the total weight of the mixture; according to the water-solid ratio is 1.2 to prepare the curing agent slurry;

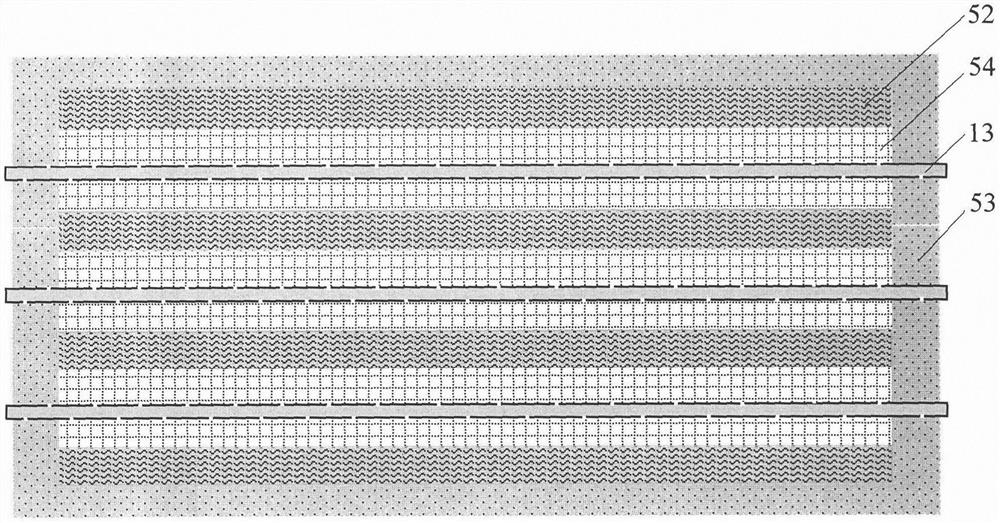

[0050] b. The planting plant on the desert site is scheduled to be Populus euphratica, the processing depth of the mixing head 9 is set to 50cm, the soil loosening depth of the rotary plow 7 is 30cm, the width of the greening grid area is 2.0m, and the mobile form of the crawler vehicle A5 is set For row-by-row movement (such as image 3 ), the orientation signal of mechanical walking is set, and is sent by transmitter 11;

[0051] c. open the pump A25 and the control valve A27, adjust the control valve A27 to make the content of ...

Embodiment 2

[0057] a. On the basis of the steps of the above method, if the thickness of the desert soil layer is 1.0-3.0m, the content of fine sand is 60%, and the moisture content is less than 4%, then the mixture of magnesia and slag is selected as the main curing agent, magnesia powder The content accounts for 50% of the total weight of the mixture; the curing agent slurry is prepared according to the water-solid ratio of 1.2;

[0058] b. The planting plant on the desert site is scheduled to be camel thorn, the processing depth of the mixing head 9 is set to 30cm, the soil loosening depth of the rotary plow 7 is 20cm, the width of the greening grid area is 1.5m, and the movement of the crawler vehicle A5 is set The form is to move vertically and then horizontally (such as Figure 4 ), the orientation signal of mechanical walking is set, and is sent by transmitter 11;

[0059] c. open pump A25 and control valve A27, adjust control valve A27 to make the content of curing agent in sandy...

Embodiment 3

[0065] a. On the basis of the steps of the above method, if the thickness of the desert soil layer is 1.0m, the content of fine sand is 30%, and the moisture content is 5-7%, then the mixture of magnesium oxide and slag is selected as the main curing agent, and magnesium oxide powder The content accounts for 30% of the total weight of the mixture; the curing agent slurry is prepared according to the water-solid ratio of 1.0;

[0066] b. The planting plants on the desert site are scheduled to be halophytes, the processing depth of the mixing head 9 is set to be 25cm, the soil loosening depth of the rotary plow 7 is 10cm, the width of the greening grid area is 1.0m, and the tracked vehicle A5 is set. The form of movement is first vertical and then horizontal (such as Figure 4 ), the orientation signal of mechanical walking is set, and is sent by transmitter 11;

[0067] c. Open the pump A25 and the control valve A27, adjust the control valve A27 to make the content of the curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com