Rolling element, support roller, and laundry treatment device

A technology for treating tools and rolling elements, applied in the field of rolling elements, can solve the problems of high cost of variant solutions and expensive rolling bearings, and achieve the effects of low cost and high resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

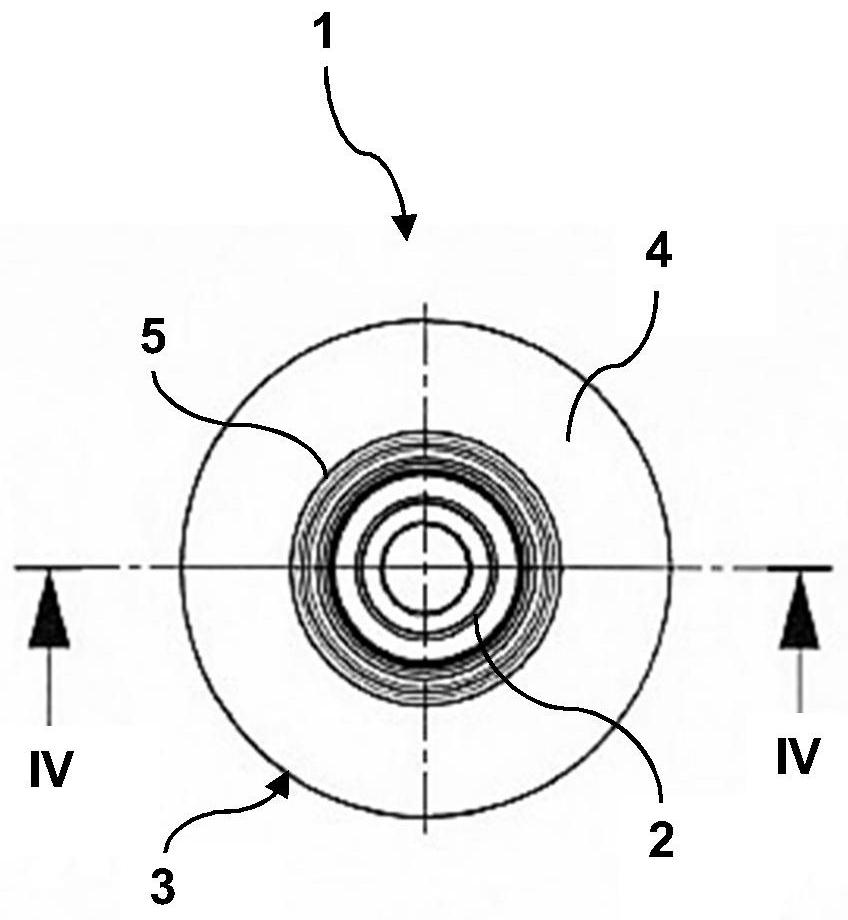

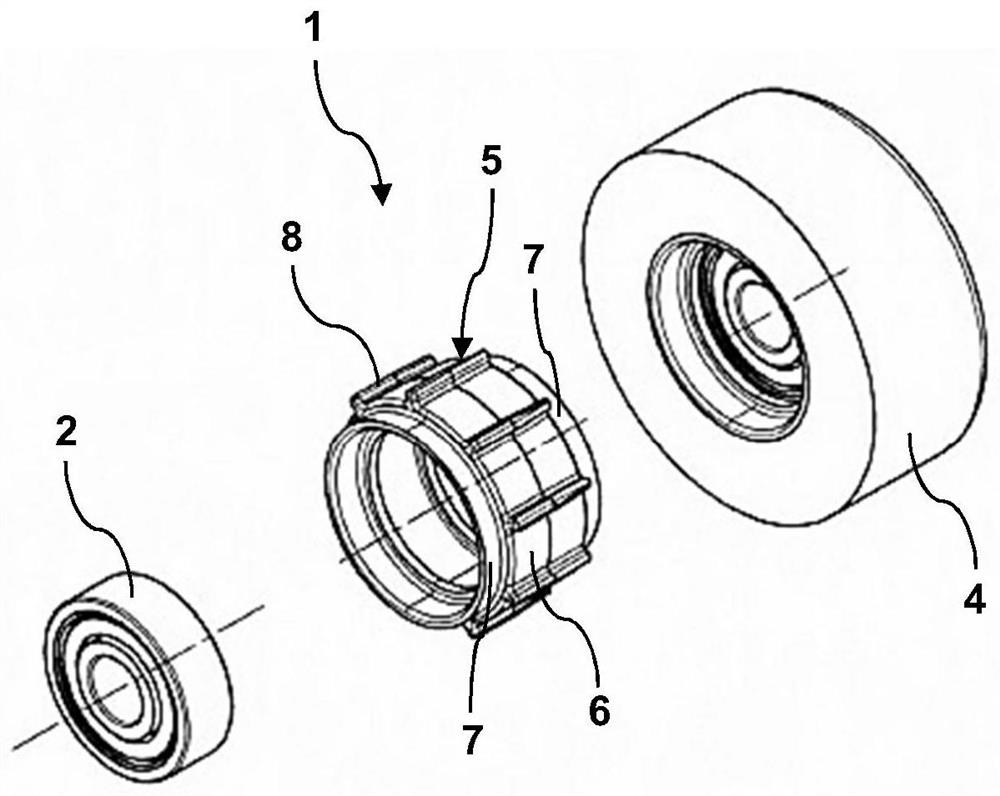

[0038] figure 1 Shown is a schematic side view of an exemplary embodiment of a support roller 1 according to the invention for guiding and / or supporting the unshown laundry treatment appliance configured as a front loader. A not-shown front or rear section of the laundry drum is shown.

[0039] The supporting rolling element 1 has a radial rolling bearing 2 and a rolling body 3 , which surrounds the radial rolling bearing 2 radially on the outside and is connected to the radial rolling bearing 2 .

[0040] The rolling elements 3 have tire parts 4 which can come into contact with the laundry drum. The tire part 4 can be produced from polyurethane. The tire member 4 may have a Shore A durometer of 85.

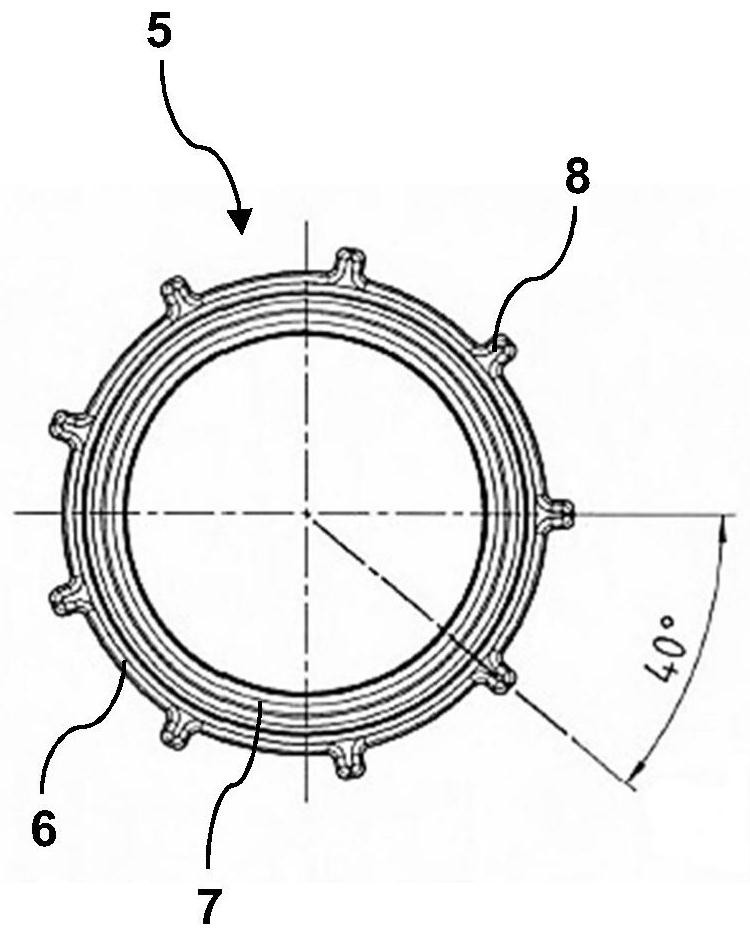

[0041] Furthermore, the rolling body 3 has a rim 5 arranged radially on the inside with respect to the tire part 4 . The rim 5 can be produced from fiber-reinforced polybutylene terephthalate.

[0042] A form-fit acting in the circumferential direction is formed between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com