Pure bending moment yield damper device

A damper and pure bending technology, which is applied in the direction of building components, building structures, earthquake resistance, etc., can solve the problems of local plastic hinges, reduced elongation of welded joints, easy generation of axial force at extended parts, and uneven pressure distribution. Achieve the effects of good energy consumption, high energy absorption and shock absorption performance, and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

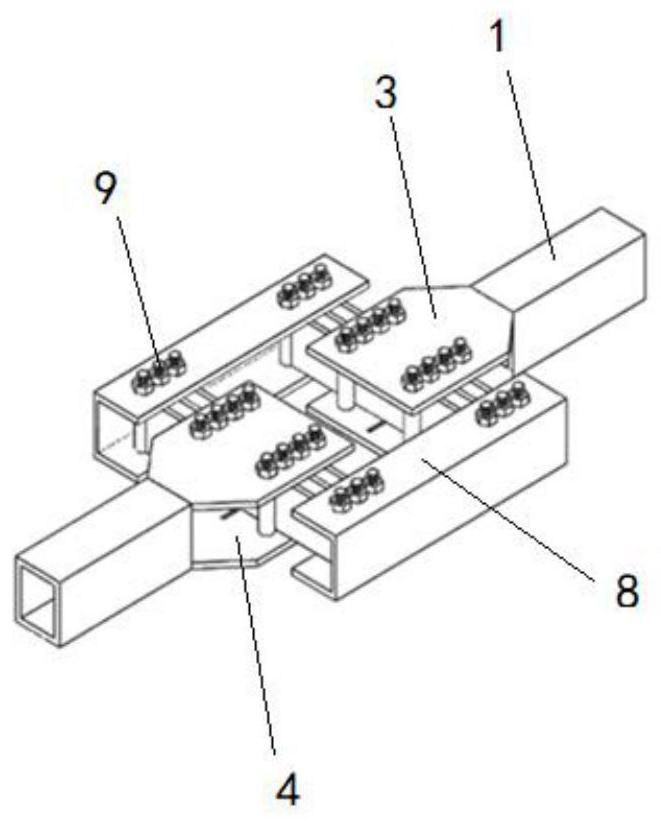

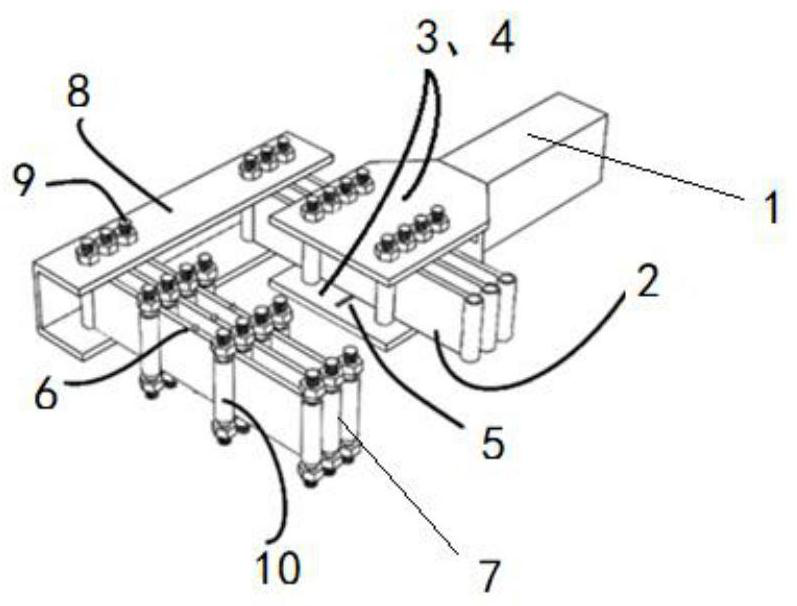

[0051] Such as Figure 1~2 As shown, the pure bending moment yield damper device of the present invention includes a support frame connection port 1, an energy dissipation plate 2, an upper supporting plate 3, a lower supporting plate 4, a guide groove 5, a shear force key 6, and a lateral rolling support 7 , Lateral constraint masonry 8, bearing pin 9, middle rolling bearing 10;

[0052] The connection port 1 of the support frame is two square columns; the support plate includes an upper support plate 3 and a lower support plate 4, and the upper support plate 3 and the lower support plate 4 are two pieces respectively, and the upper support plate 3 is respectively symmetrically welded to the support frame. Above the opening 1, the lower supporting plate 4 is respectively symmetrically welded below the connecting port 1 of the support frame; the supporting plate includes two rows of openings; guide groove 5;

[0053] The rolling support is a hollow cylindrical tube, and the ...

Embodiment 2

[0061] The material of the energy dissipation plate is shape memory alloy; the material of the support frame connection, supporting plate, shear key, rolling bearing and lateral restraint masonry is alloy steel;

[0062] Energy dissipation board 2 is divided into two groups, and the number of each group is 5 pieces

[0063] The ratio of the distance between the energy dissipation panels in each group of energy dissipation panels to the distance between two groups of energy dissipation panels is 1:3;

[0064] The gap distance between the lateral constraint masonry and the upper and lower pallets is 1 / 2 of the pallet width;

[0065] Others are the same as in Example 1, and the pure bending moment yield damper device in Example 2 of the present invention is obtained.

Embodiment 3

[0067] The material of the energy dissipation plate is steel with low yield point; the material of the support frame connection, supporting plate, shear key, rolling bearing and lateral restraint masonry is alloy steel;

[0068] Energy dissipation board 2 is divided into two groups, and the number of each group is 6 pieces

[0069] The ratio of the distance between the energy dissipation panels in each group of energy dissipation panels to the distance between two groups of energy dissipation panels is 1:8;

[0070] The gap distance between the lateral constraint masonry and the upper and lower pallets is 1 / 3 of the pallet width;

[0071] Others are the same as in Example 1, and the pure bending moment yield damper device of Example 3 of the present invention is obtained.

[0072] Take embodiment 1 as an example to introduce the working process of the pure bending moment yield damper device of the present invention:

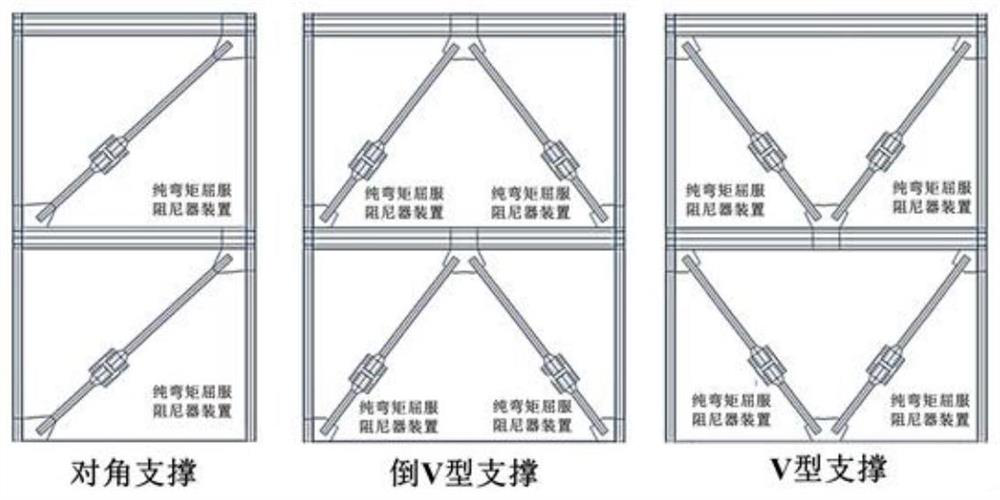

[0073] Connect the connection port of the support frame t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com