Plunger pump with corrugated-pipe-shaped diaphragm piece

A technology of plunger pump and diaphragm, which is applied in the direction of pump components, variable displacement pump components, and components of pumping devices for elastic fluids, etc. It can solve the problems of debris pollution, low precision, and fast wear of the plunger, etc. Achieve the effect of reducing friction, high precision and stable conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

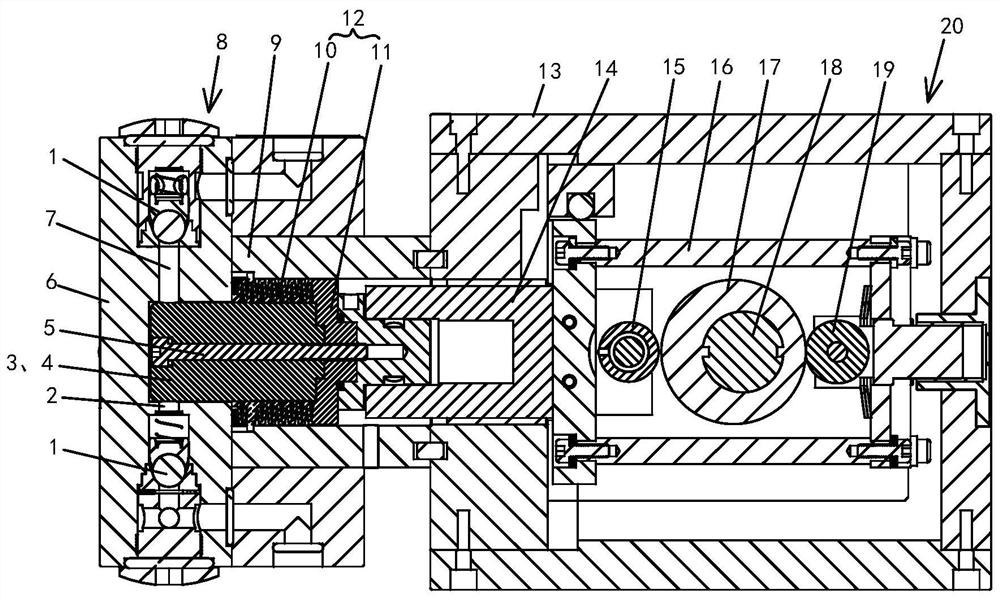

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] Please refer to figure 1 , the plunger pump includes a cylinder 8 , a plunger 4 , a bellows-shaped diaphragm 12 , and a reciprocating power mechanism 20 . Wherein, the cylinder block 8 includes a cylinder body portion 9 and a cylinder head portion 6, the cylinder body portion 9 and the cylinder head portion 6 are combined by a first screw, and a liquid inlet 2 and a liquid outlet are provided on the cylinder head portion 6. 7. The bellows-shaped diaphragm 12 is arranged in the cylinder body 9, and the edge of the mouth of the bellows-shaped diaphragm 12 is crimped between the cylinder body 9 and the cylinder head 6, thereby forming a The variable volume liquid delivery chamber 3 connected with the liquid inlet 2 and the liquid outlet 7, the volume of the liquid delivery chamber 3 changes with the expansion and contraction of the bellows-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com