Wind turbine generator blade tip and tower drum distance monitoring method and system

A technology for wind turbines and towers, which is used in wind turbine monitoring, wind turbines, mechanical measuring devices, etc., can solve problems such as poor stability, damage to tower structure and paint film, and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

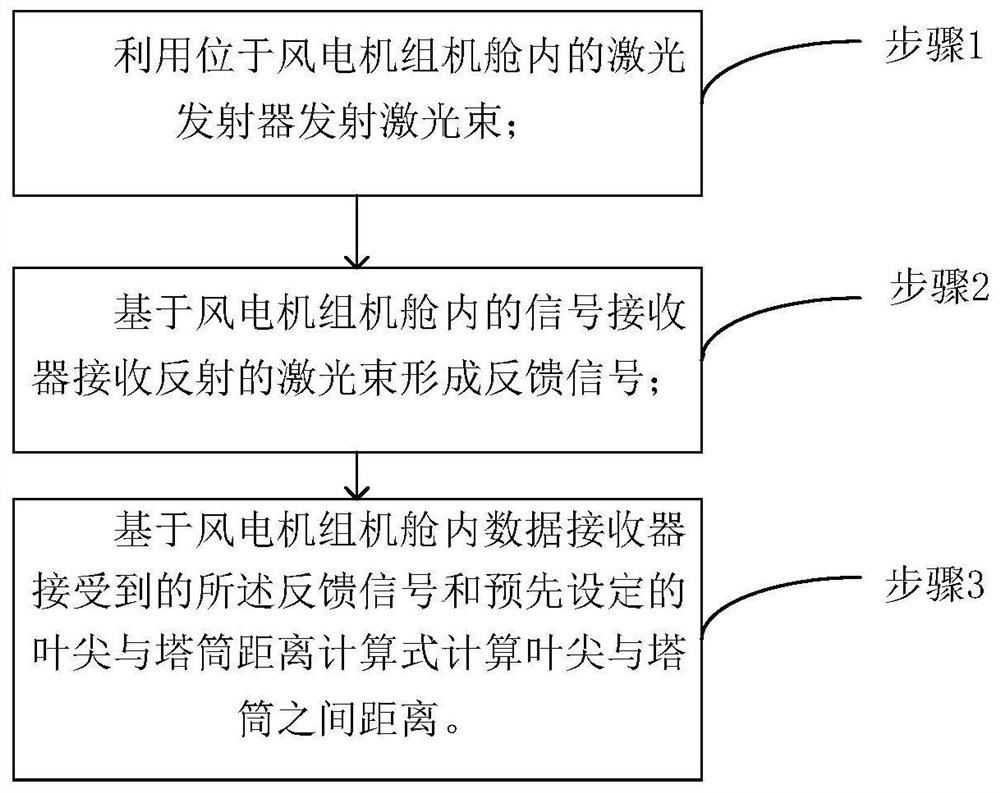

[0046] Such as figure 1 A method for monitoring the distance between the tip of the wind turbine and the tower includes:

[0047] Step 1: Use the laser transmitter located between the front tower and the blades in the wind turbine nacelle to emit a laser beam;

[0048] Step 2: Form a feedback signal based on the signal receiver in the wind turbine nacelle receiving the reflected laser beam;

[0049] Step 3: Calculate the distance between the blade tip and the tower based on the feedback signal received by the data receiver in the wind turbine nacelle and the preset formula for calculating the distance between the blade tip and the tower.

[0050] Among them, step 1 specifically includes: the installation position of the laser generator is in the front half of the nacelle, and the installation point is not unique. That is, it can be installed at the position of the nacelle bottom plate on the central axis of the nacelle, or at the position of the nacelle bottom plate on one s...

Embodiment 2

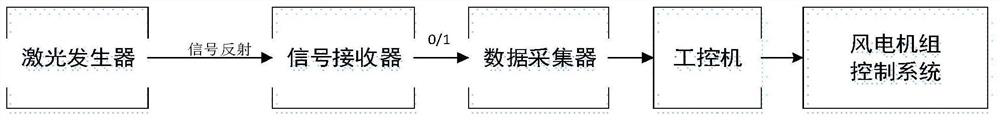

[0066] Based on the same idea, the present invention designs a wind turbine blade tip-tower distance monitoring system,

[0067] Laser generator, signal receiver and data collector;

[0068] The laser generator is installed between the front tower and the blades in the wind turbine nacelle for emitting laser beams;

[0069] The signal receiver is connected with the laser generator for receiving the feedback signal formed by the reflected laser beam;

[0070] The data collector is connected to the signal receiver for receiving the feedback signal transmitted by the signal receiver, and calculating and displaying the distance between the blade tip and the tower based on the feedback signal;

[0071] Both the signal receiver and the laser receiver are located inside the wind turbine nacelle.

[0072] Preferably, the bottom plate of the wind turbine cabin is provided with a hole, and the laser generator is fixed at the hole;

[0073] The hole is set at the central axis of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com