Fiber broken filament collecting device and using method thereof

A collection device and fiber technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of insufficient collection of fiber wool and inaccurate data of wool yarn, and achieve accurate wear resistance test results, good collection effect, Avoid the effect of abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

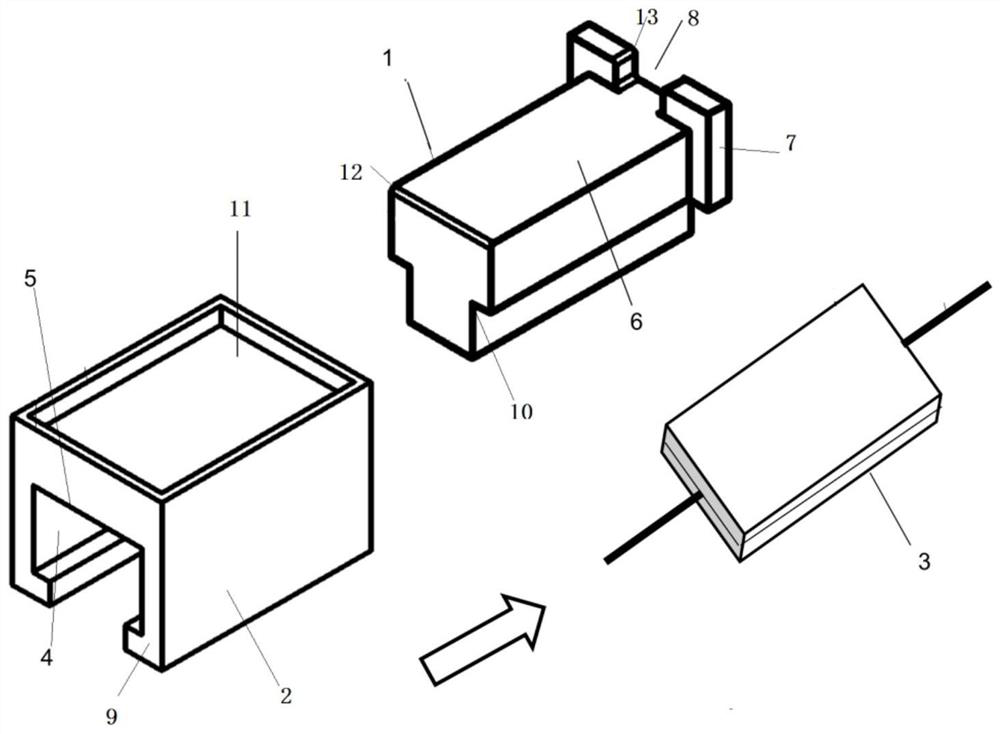

[0034] A fiber fluff collection device, comprising an upper pressing block 2, a base 1 nested in the upper pressing block 2, and two collecting pieces 3 placed on the base 1 and positioned by pressing the upper pressing block 2;

[0035] Wherein: the upper pressing block 2 is formed with a slot 4 for insertion of the base 1, the slot 4 is in the same pulling direction as the fiber bundle, and the top of the slot 4 forms a horizontal pressing surface 5, A horizontal upper support surface 6 is formed on the top of the base 1 , and two collection sheets 3 are located between the lower pressing surface 5 and the upper support surface 6 , and the fibers pass through horizontally between the two collection sheets 3 .

[0036] The surface of the lower pressing surface 5 and the upper supporting surface 6 is horizontal and smooth, and there is a gap of 2-15mm between them, which ensures that the collecting sheet has a corresponding space to be placed, and it is flat and free of pleats ...

Embodiment 2

[0044] This embodiment introduces its preferred structure on the basis of Embodiment 1.

[0045] As a preferred mode, the end of the base 1 in the direction in which the fiber bundle leaves is fixed with a block 7 that limits the position of the upper pressing block 2 in the horizontal direction, and the middle of the block 7 is provided with a Fiber channel 8.

[0046] The height of the block 7 is 2-15mm, and the height of the block 7 is greater than the height of the gap between the pressing surface 5 and the upper supporting surface 6, which can prevent the upper pressing block from passing through the block 7. The width of the fiber channel 8 is 5-20 mm, and the fiber channel ensures the normal passage of the fiber bundle.

[0047] The block 7 prevents the upper pressing block 2 or the collecting sheet 3 from horizontally displacing when there is a large traction force and pulling speed, and prevents the collecting sheet 3 from wrinkling or being cheap or even being dragg...

Embodiment 3

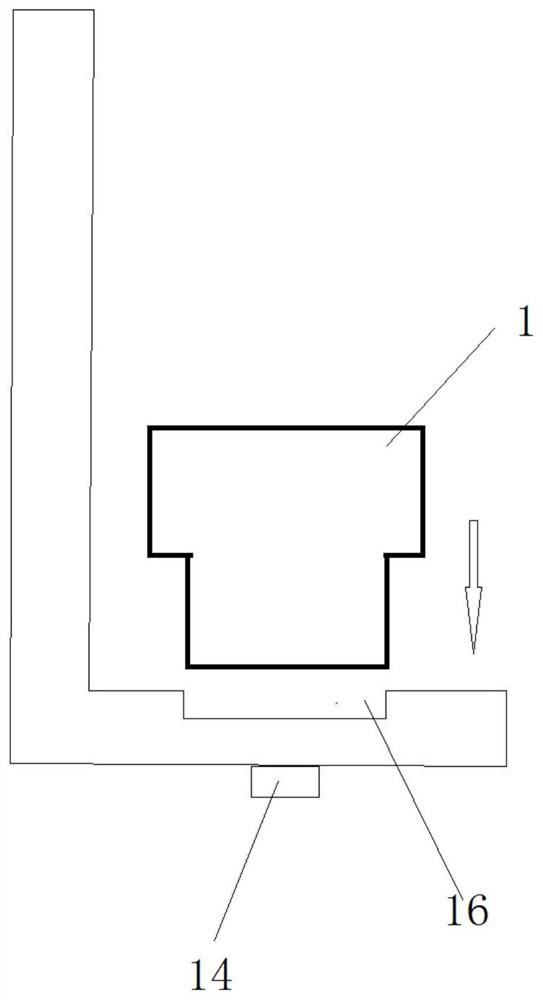

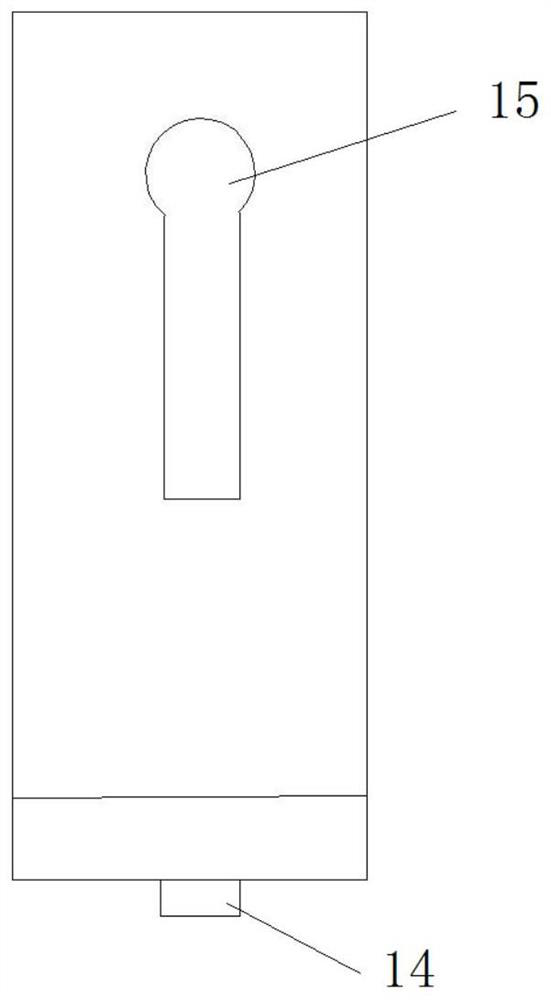

[0055] This embodiment introduces the fixing plate on the basis of Embodiment 1 and Embodiment 2.

[0056] like figure 2 As shown, it also includes an L-shaped fixing plate, the bottom horizontal plate of the L-shaped fixing plate is provided with a groove 16 for accommodating the bottom of the T-shaped base 1, and the bottom of the L-shaped fixing plate is provided with a fixing nut 14, In order to fix the T-shaped base 1 on the L-shaped fixing plate, a strip hole 15 is formed on the vertical plate of the L-shaped fixing plate to pass the L-shaped fixing plate through the strip. The hole 15 is fixed on the wool wear resistance test device with a nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com