Casing containment analysis method for blade offset loss

An analysis method and inclusive technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the complexity of the impact process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

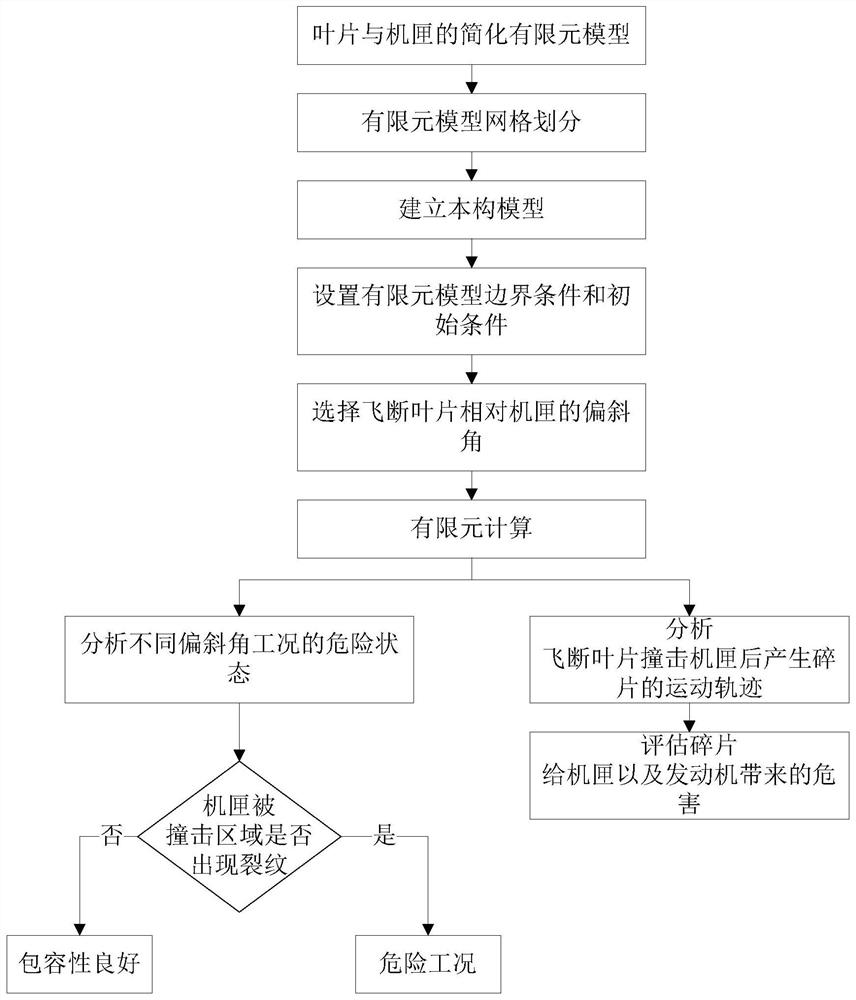

[0025] Such as figure 1 As shown, a casing inclusive analysis method for blade offset loss in this embodiment includes the following steps:

[0026] (1) Establish the finite element model of the blade and casing; in this embodiment, the casing model established includes the turbine casing and the fan casing. In the modeling process, in order to simplify the modeling and shorten the calculation time, the engine casing Simplify the real structure of the casing, remove unnecessary features and parts such as blade roots, discs, holes, chamfers, roundings, bosses, etc., but retain all the features of the impacted area of the casing as much as possible.

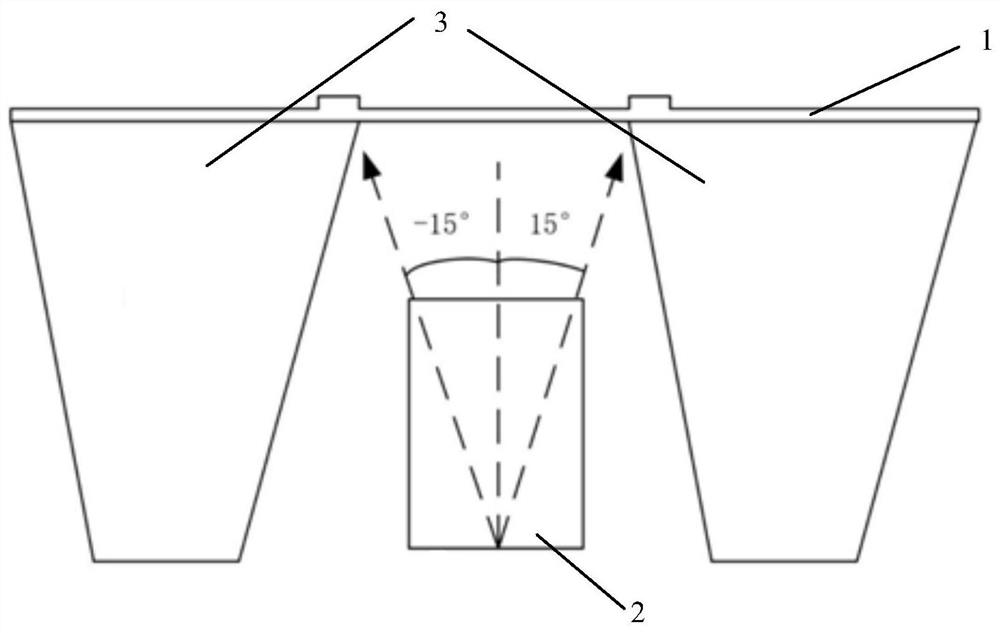

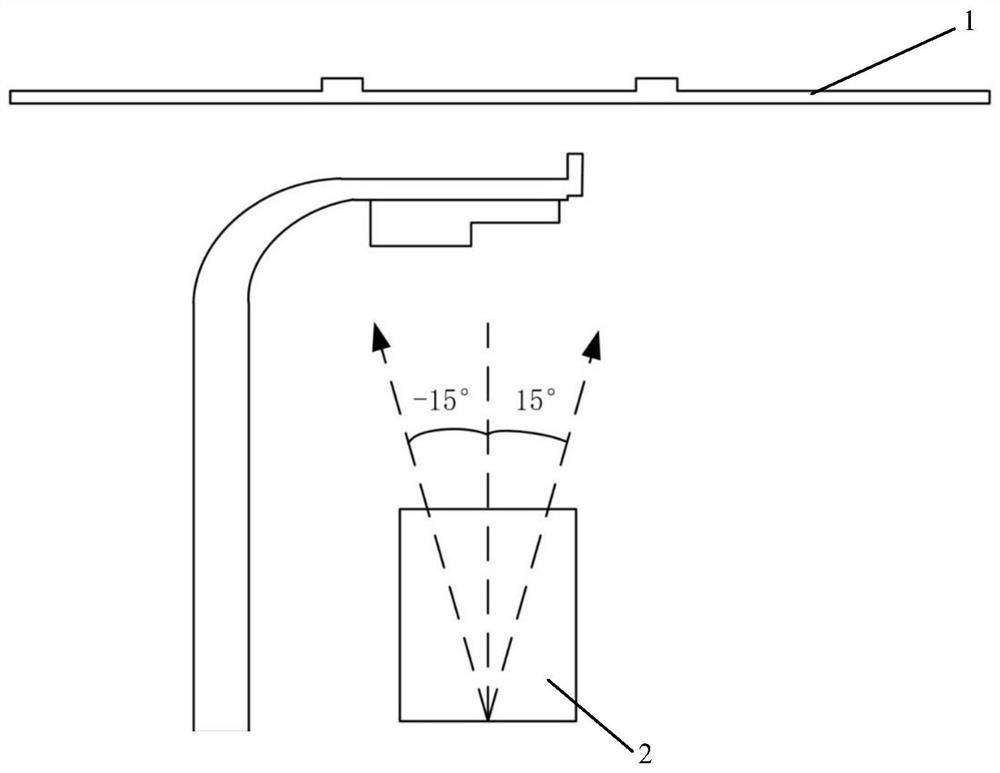

[0027] Because the main research is on the impact process of the blade after it breaks off and the casing, and the impact mainly occurs at the blade tip and the blade body, the blade root does not participate in the impact, and the disc only plays the role of driving the rest of the blades to rotate. The blade 2 is cut from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com