Soft package battery and preparation method thereof

A soft-pack battery and cell technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as increasing battery production costs, water ingress, and cell failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

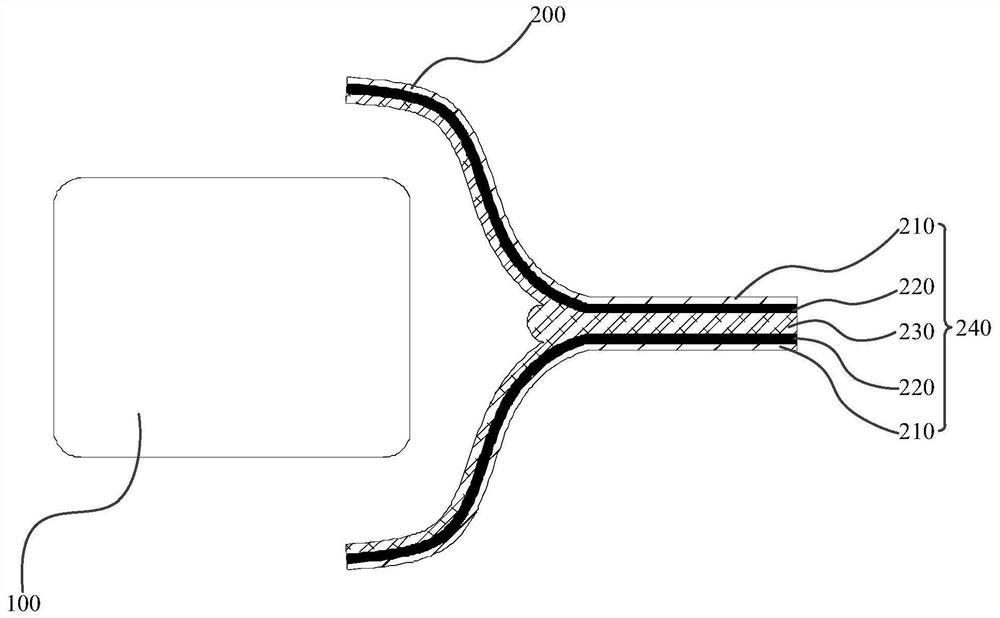

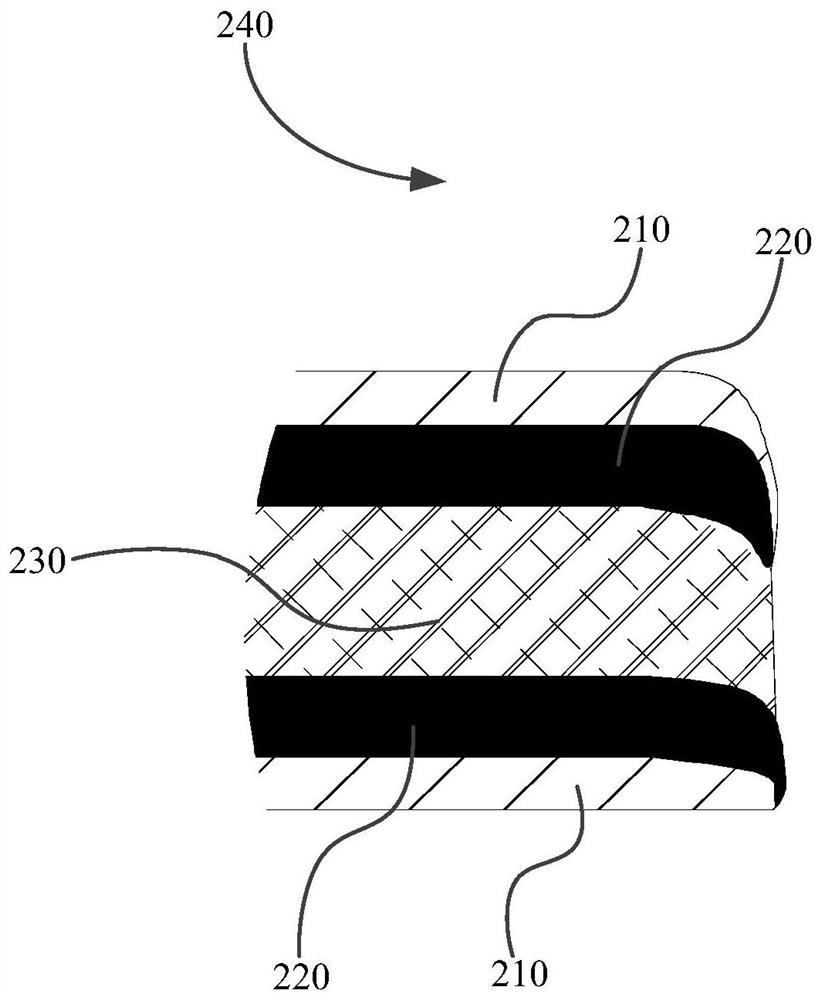

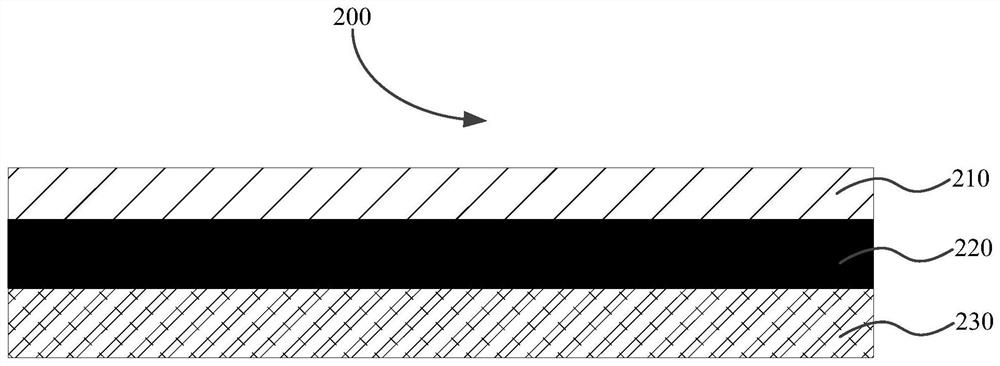

[0049] image 3 Schematic diagram of the structure of the aluminum-plastic film provided in this embodiment; Figure 4 Schematic diagram of part of the structure of the pouch battery provided in this embodiment; Figure 5 for Figure 4 A schematic diagram of the structure of a right end of the aluminum plastic film; Figure 6 for Figure 5 Schematic diagram of the experimental results of the aluminum plastic film structure compared with the existing technology.

[0050] This embodiment provides a pouch battery, including a battery cell 100 and an aluminum-plastic film 200 covering the battery cell 100. Those skilled in the art can understand that the battery cell 100 is a component that stores and releases electric energy in the battery, which includes Positive and negative plates. During the charging process of the battery cell 100, lithium ions are extracted from the positive electrode sheet and embedded in the negative electrode sheet. During the discharge process, lit...

Embodiment 2

[0060] Figure 7 for Figure 4 Schematic diagram of the structure of another right end of the aluminum plastic film; Figure 8 for Figure 7 Schematic diagram of the experimental results of the aluminum plastic film structure compared with the existing technology.

[0061] Such as Figure 7 As shown, on the basis of Embodiment 1, this embodiment provides another pouch battery, specifically, the downwardly bent part of the aluminum layer 220 on the upper right end of the packaging part 240 and the aluminum layer 220 on the lower right end of the packaging part The upwardly bent parts are in contact with each other, that is, the bent section 221 of the aluminum layer 220 above the PP layer 230 of the packaging part 240 is in contact with the bent section 221 of the aluminum layer 220 below the PP layer 230 of the packaging part 240 . It is easy to understand that the right end of the aluminum layer 220 above the package 240 and the right end of the aluminum layer 220 below t...

Embodiment 3

[0070] On the basis of the above-mentioned embodiments, this embodiment provides a method for preparing a pouch battery, so as to form two bent sections 221 at the right end of the packaging part 240, and then use the bent sections 221 to cover the right end surface of the PP layer 230 , improve the waterproof performance of the pouch battery.

[0071] The manufacturing method of the pouch battery provided in this embodiment includes: providing a battery cell and an aluminum-plastic film 200, and punching the aluminum-plastic film 200 to form a pit for accommodating the battery cell. The battery cell is placed inside the pit, and the aluminum plastic film 200 is folded in half for packaging. It is easy to understand that packaging includes a series of processes such as top-side sealing, liquid injection, pre-sealing, and secondary sealing. This embodiment does not limit the specific process of packaging, and those skilled in the art can set it according to actual needs.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com