Active control of radial etch uniformity

A uniformity and etching technology, used in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve problems such as non-uniformity of etched wafers, increase radial etching uniformity, and achieve radial etching uniformity. , the effect of frequency and phase reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

[0024] The following embodiments describe systems and methods for actively controlling radial etch uniformity. Obviously, the presented embodiments may be practiced without some or all of these specific details. In other instances, well known process operations have not been described in detail in order not to unnecessarily obscure the present embodiments.

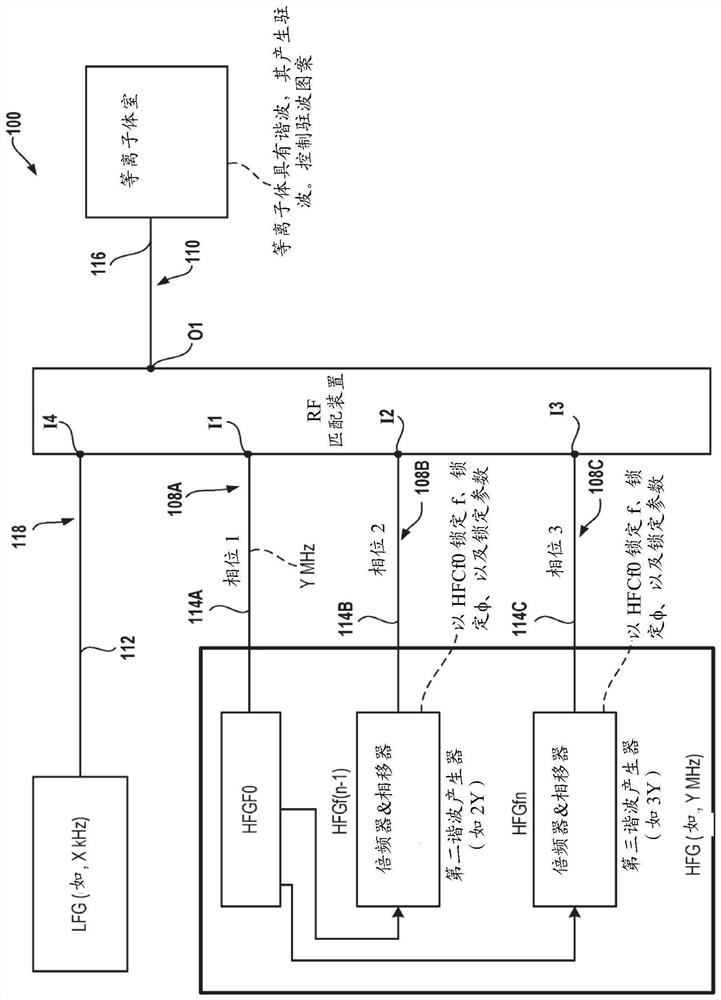

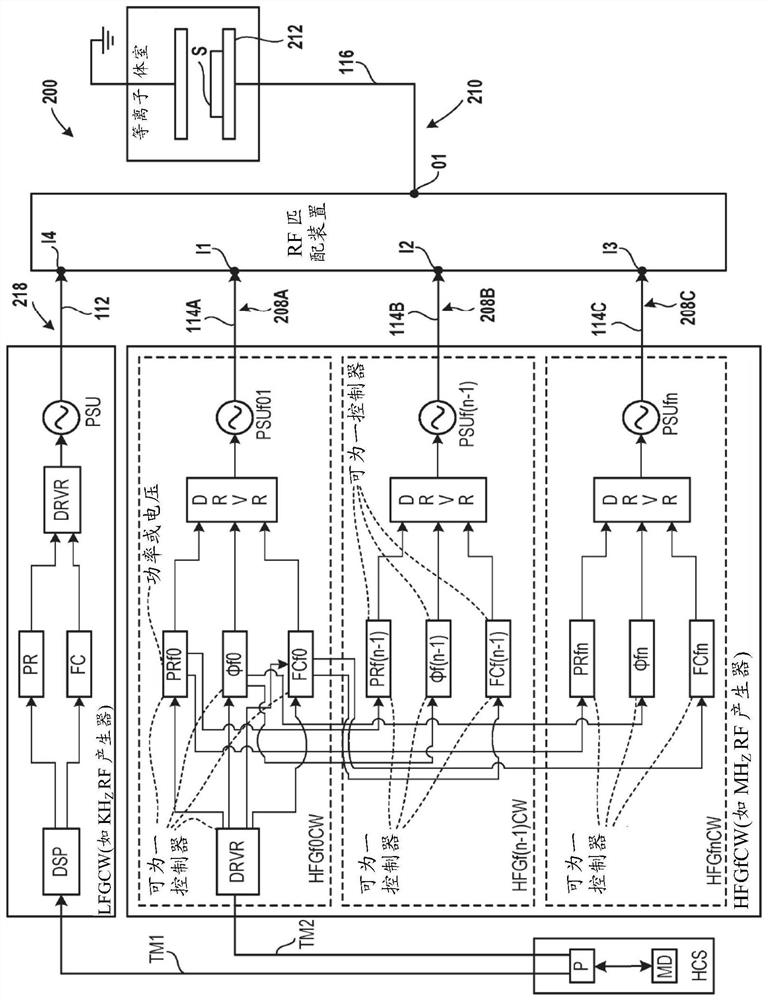

[0025] Figure 1A is a diagram of an embodiment of a system 100 illustrating controlling radial etch uniformity across a substrate surface. System 100 includes a low frequency generator (LFG) and a high frequency generator (HFG). The low frequency generator LFG is a radio frequency (RF) generator and the high frequency generator HFG is also an RF generator. System 100 also includes an RF matching device and a plasma chamber. A low frequency generator LFG is coupled via an RF cable 112 to the input I4 of the RF matching device.

[0026] The high-frequency generator HFG comprises a high-frequency sub-generator HFGf0 oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com