Plasma processing device

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of increasing the standing wave effect of the bipolar plates, the deterioration of the air flow uniformity, and the poor process results, so as to reduce the difficulty and time of maintenance, Effect of size reduction, size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

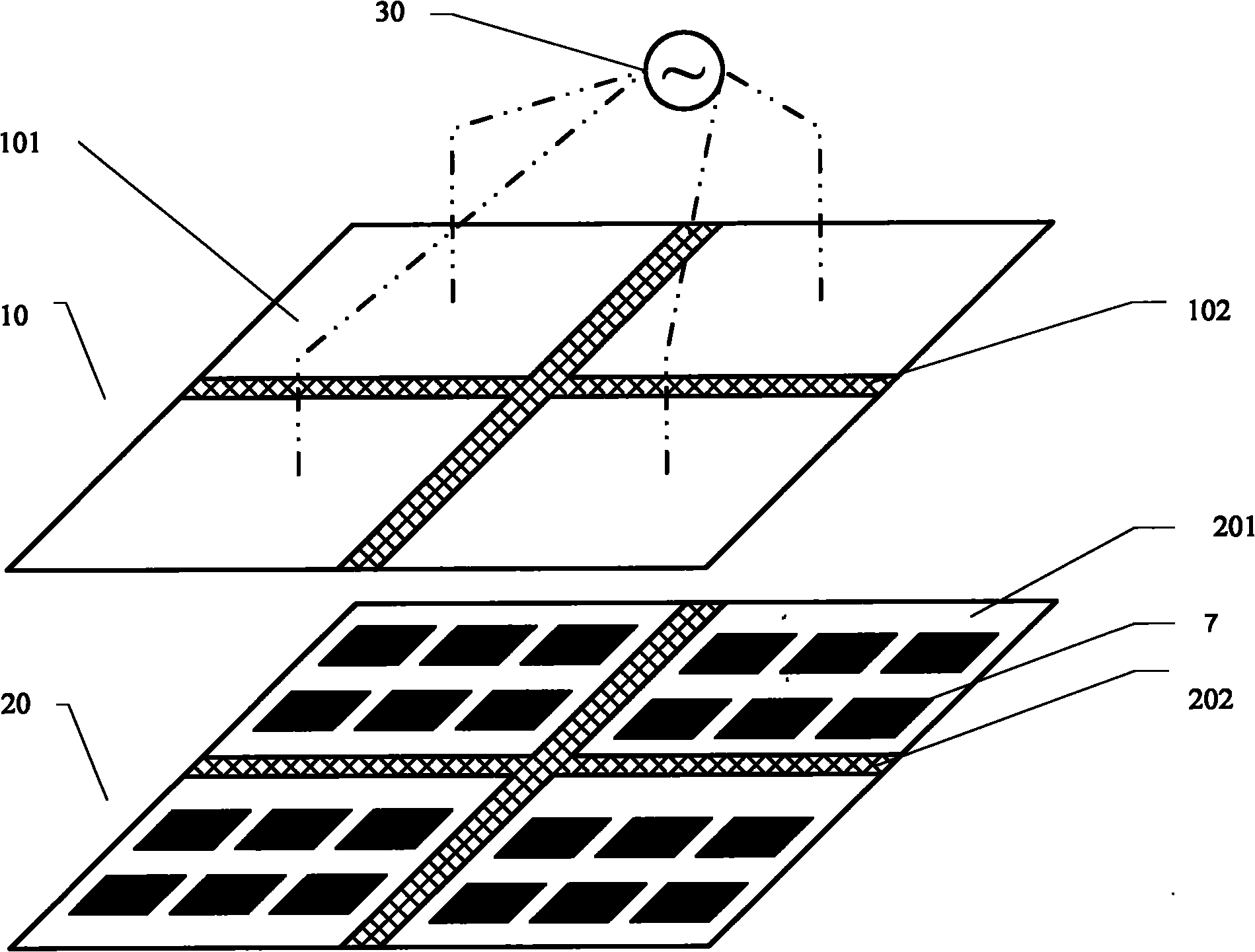

[0029] figure 2 It is a schematic diagram of the plasma processing device in this embodiment. In order to clearly illustrate the inventive point of the present invention, the structure not directly related to the inventive point, such as the reaction chamber and the vacuum device, is not shown in the figure.

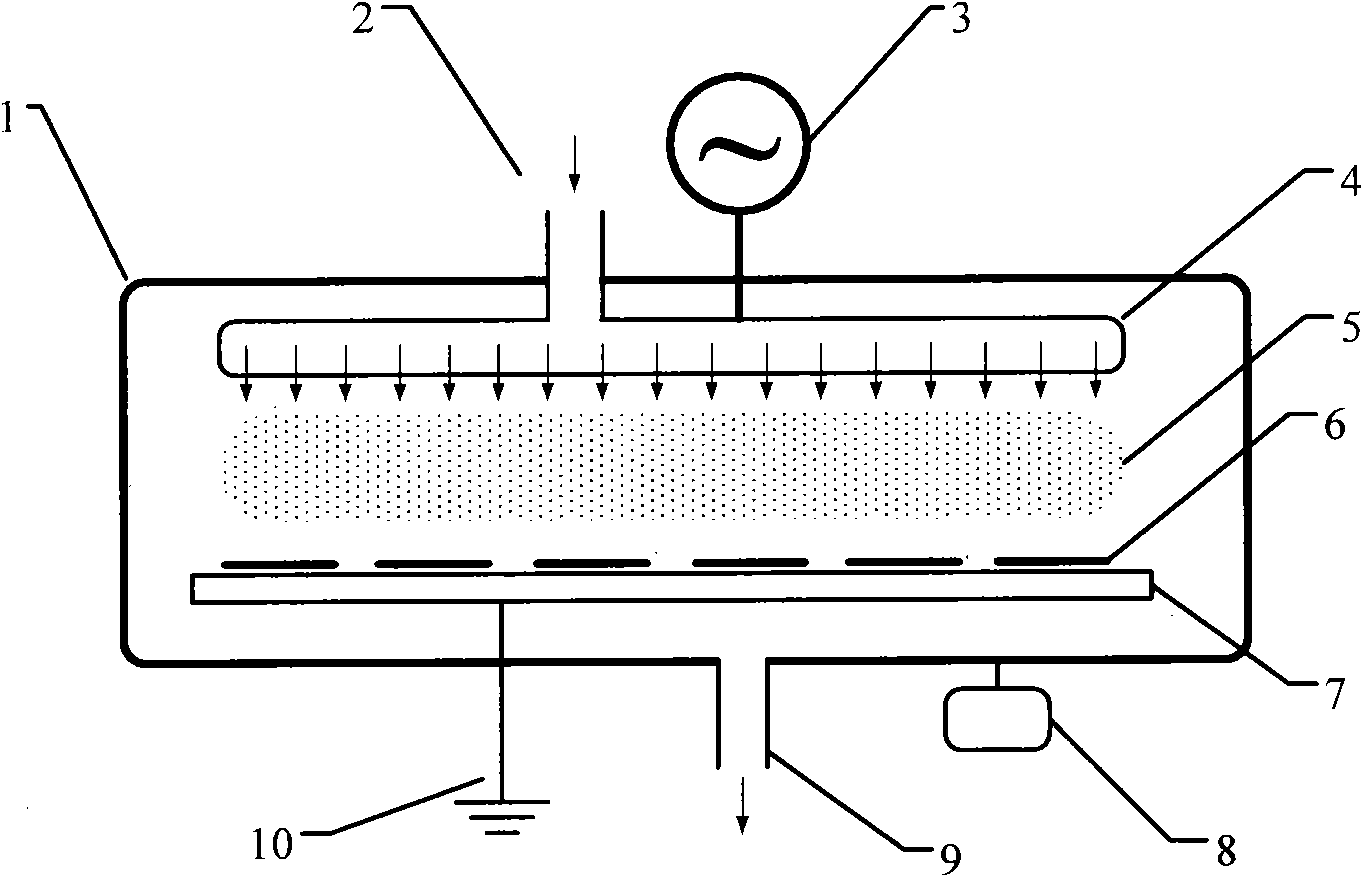

[0030] The plasma processing device includes: a reaction chamber (not shown in the figure), and a first pole plate 10 and a second pole plate 20 disposed opposite to each other in the reaction chamber. The first pole plate 10 is located on the upper part of the reaction chamber, and is generally called the upper pole plate. The upper pole plate is also a gas input device, which is connected with the gas channel and is used for inputting process gas into the reaction chamber. The second plate 20 is located at the lower part of the reaction chamber, commonly referred to as the lower plate, for carrying the wafer 70 to be processed. Plasma is generated in the space betwee...

Embodiment 2

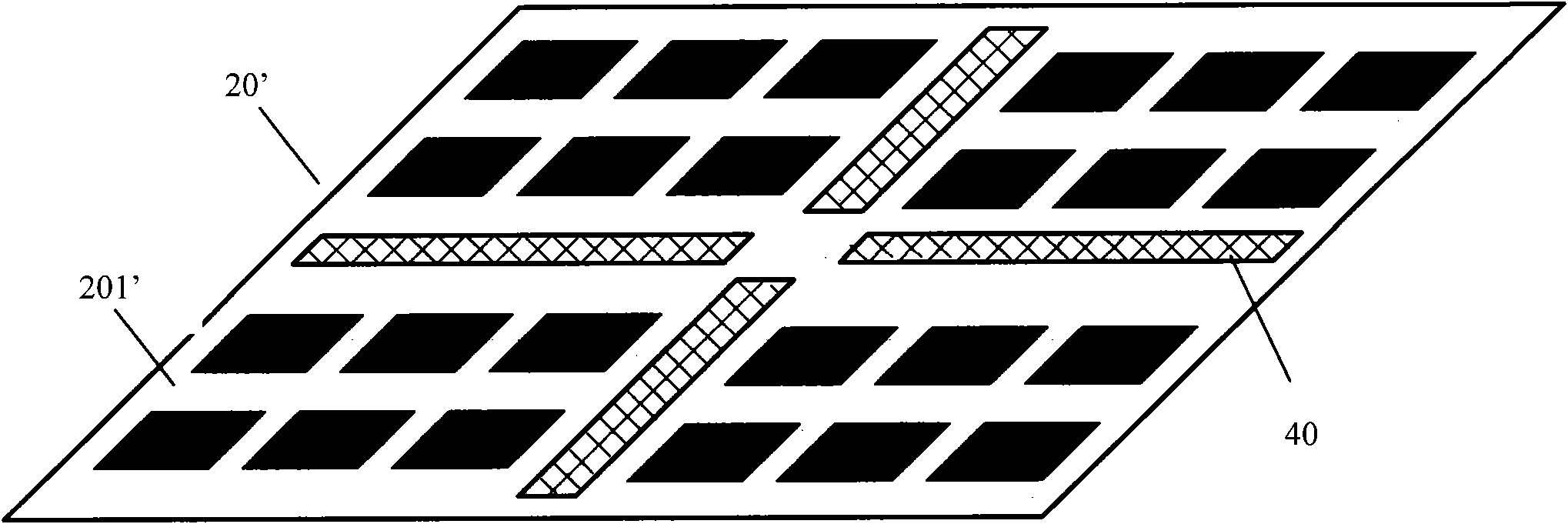

[0042] This embodiment provides another plasma processing device, which differs from the first embodiment only in the structure of the second pole plate (ie, the lower pole plate). image 3 It is a schematic diagram of the second plate of the plasma processing device in this embodiment.

[0043] Such as image 3 As shown, the second pole plate 20' is not composed of a plurality of sub-plates, but a plurality of ventilation slits 40 are arranged in the pole plate, and each ventilation slit 40 divides the second pole plate into a plurality of sub-regions 201'. Each sub-region 201' and each first sub-plate 101 (see figure 2 ) correspond one-to-one.

[0044] Each of the sub-regions 201' has the same or similar shape as its corresponding first sub-plate, and their centers are aligned. In this way, the overall shape and position of each ventilation slit 40 corresponds to the gap of the first pole plate.

[0045] For example, see image 3 , each sub-area 201' is also substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com