A washing and drying device

A kind of equipment and floor washing technology, which is applied in the direction of cleaning equipment, cleaning carpets, cleaning floors, etc., can solve the problem that the brush plate and squeegee cannot adapt to different ground conditions, the brush plate and squeegee cannot adapt to different ground conditions, and the washing The floor washing effect of the machine is not good enough to achieve the effect of guaranteeing the washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

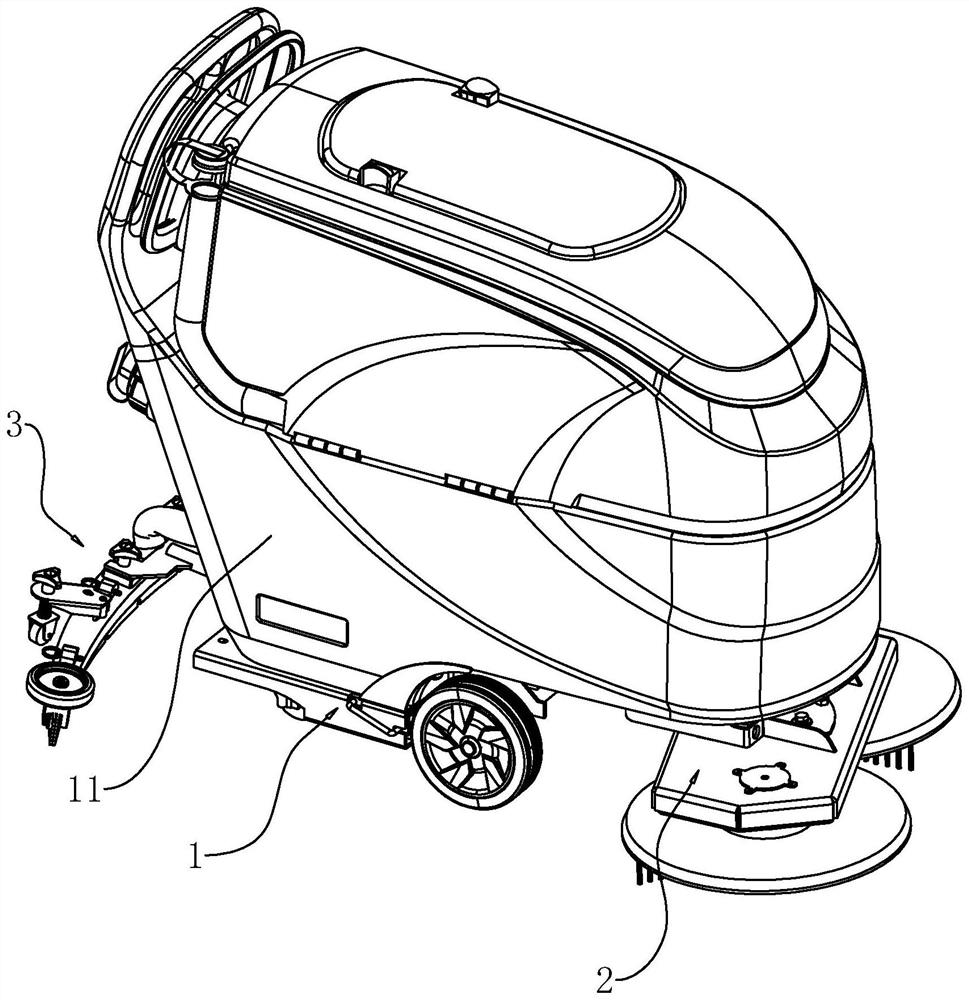

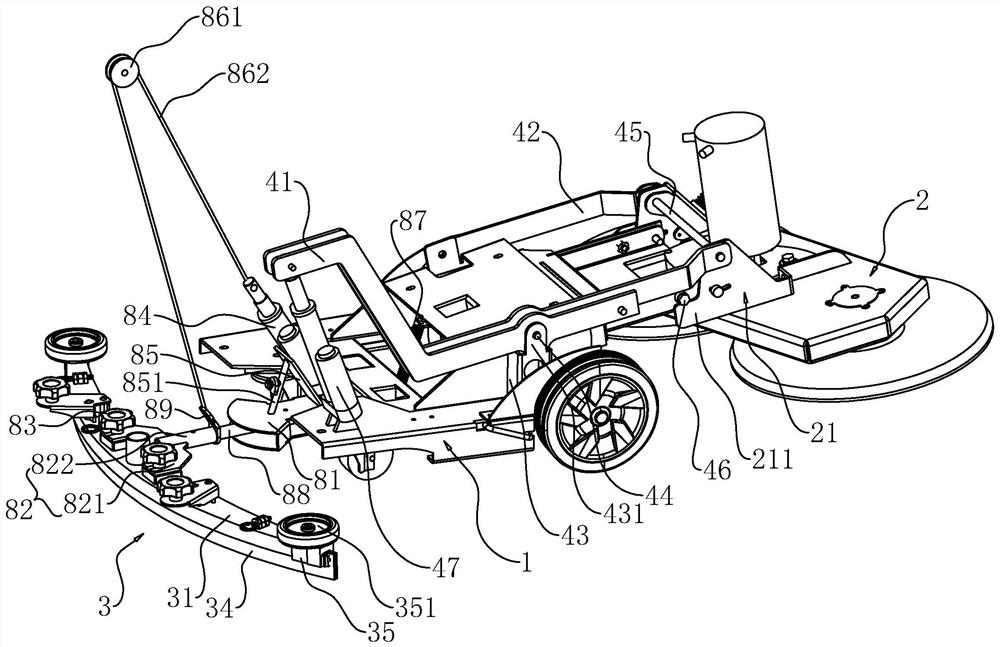

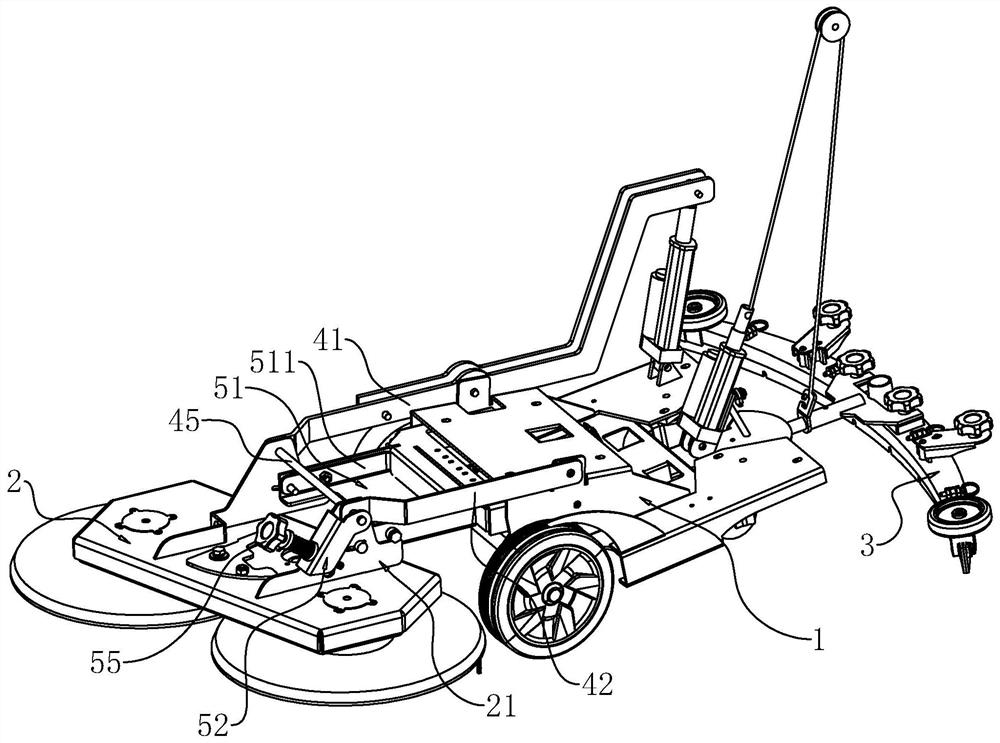

[0056] Example 1, reference figure 1 with figure 2 The washing liquid drying apparatus includes a rack 1, a brush disk 2 and a water absorbent 3, and the frame 1 is a sheet metal, and the sheet metal has the characteristics of light weight and high strength, so the rack 1 can be maintained at the same time A preferred strength, the rack 1 is fixedly provided with a water tank 11. Refer figure 2 The frame 1 is provided with a first lifting structure that controls the lifting and falling of the brush 2. The second lifting structure that controls the absorbent sand 3 is lifted.

[0057] Refer figure 2 The first lifting structure includes a swing arm group hinged to the left and right sides of the frame 1, and in the present embodiment, the swing arm group includes the first swing arm 41 and the second swing arm. 42. The first swing arm 41 and the second swing arm 42 are also a sheet metal member such that the first swing arm 41 and the second swing arm 42 also have the characteristic...

Embodiment 2

[0099] Example 2 Figure 12 In the case where the water absorbent head 32 is opened, the water absorbing head 32 is opened, and the water tank 91 is opened on both sides of the water absorbent hole 321, and the water tank 91 on both sides is connected to the water absorbent hole 321, the water tank 91 The shape of the corresponding suction head 32 extends in the shape of a circular arc, and the groove width of the water guide groove 91 is gradually reduced by one end of the absorbent hole 321 away from the absorbent hole 321.

[0100] The implementation principle of a washing suction drying apparatus according to the example of the present application is that the water absorbing head 32 is in water, and the water tank 91 can guide the sewage acceleration into the water absorbent hole 321, so that the sewage is easily inhaled to the water absorbent head 32, Improve the water absorption effect of the absorbent 3.

Embodiment 3

[0101] Example 3, reference Figure 13Unlike the embodiment, the bumps 921 are disposed in that the bumps 921 are provided, and the interior of the bumps 921 is opened, and the mounting holes 922 are opened, and the mounting holes 922 are connected to the interior of the bumps 921. The water absorbent head 32 is provided with a mounting block 923, and the mounting block 923 can be fixed into the bump 921 by the mounting hole 922, and the mounting block 923 is fixed between the spring latch 93, and one end of the spring latch 93 is connected to the first pull. The ring 931, the first pull ring 931 facilitates people to pull out the spring latch 93.

[0102] The implementation principle of a washing liquid drying apparatus according to the example of the present application is: by embedding the mounting block 923 of the suction head 32 into the bump 921, and the spring latch 93 passes through the mounting block 923 and the bump 921, it is possible to quickly The suction head 32 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com