Solid-liquid extraction and separation reactor

A reactor and liquid immersion technology, applied in the field of solid-liquid leaching and separation reactors, can solve the problems of low removal efficiency, time-consuming and labor-intensive, and inability to check on the machine at any time, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical content of the present invention, specific embodiments are provided below, and the present invention is further described in conjunction with the accompanying drawings.

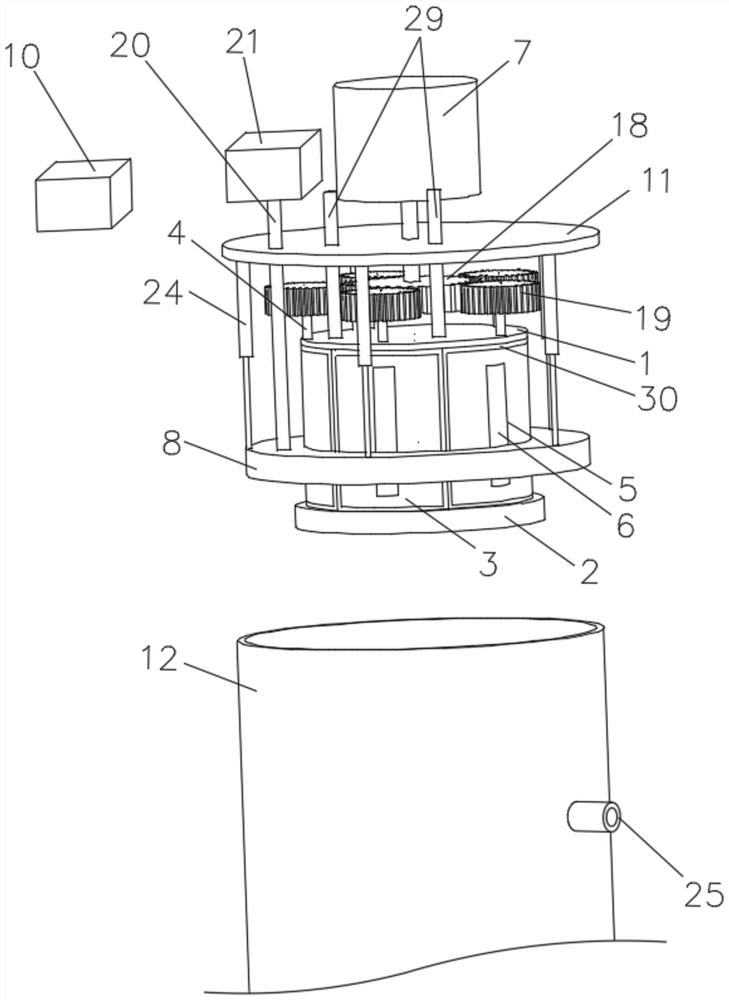

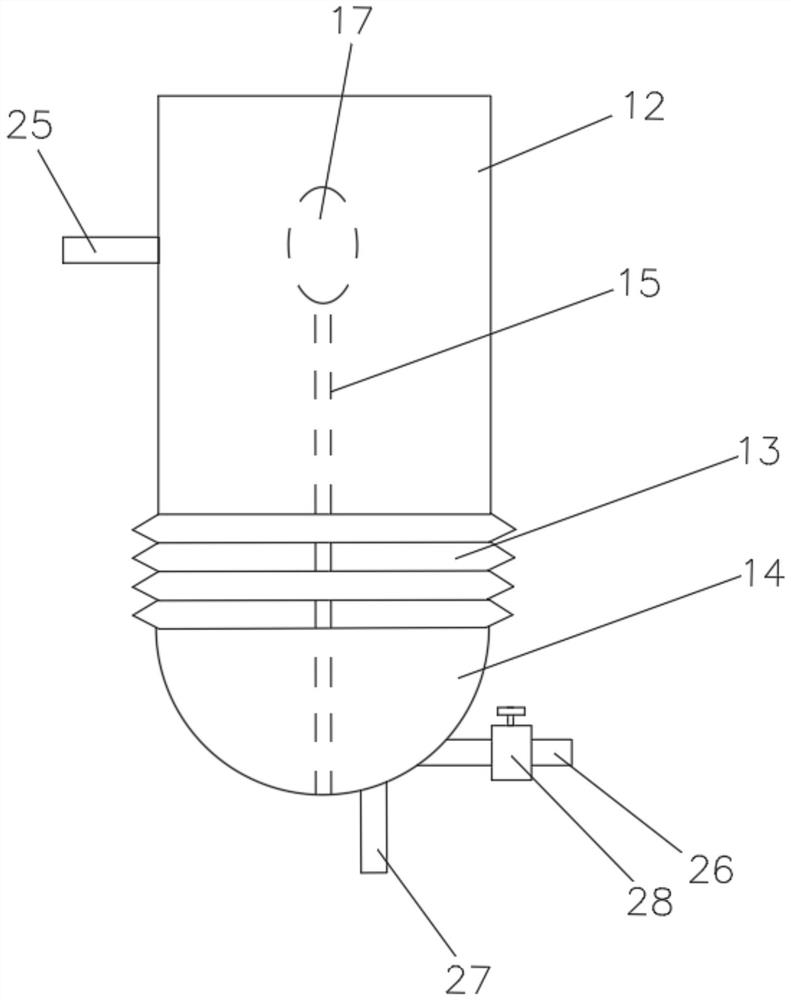

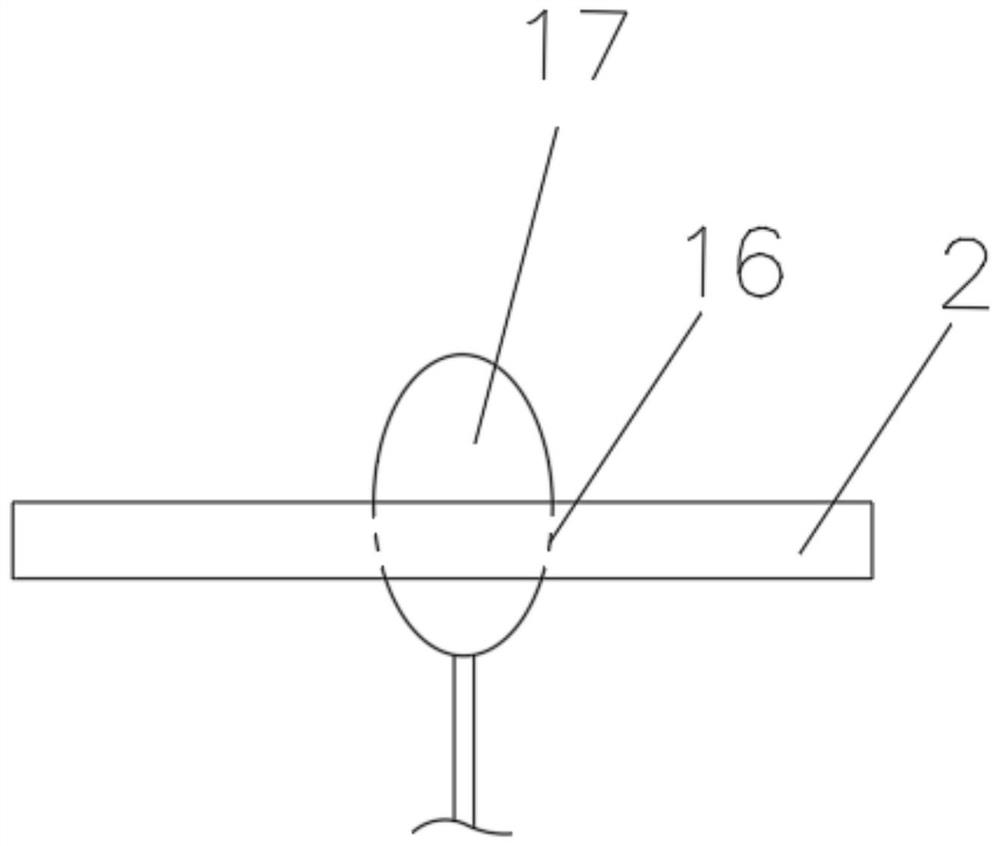

[0024] see Figure 1 to Figure 6 , a solid-liquid leaching separation reactor of the present invention, comprising a top plate 1, a bottom plate 2 and a plurality of arc-shaped plates 3, the arc-shaped plates 3 are fixedly connected with a fixed shaft 4, and the arc-shaped plates 3 are provided with A hole 5, a filter membrane 6 is arranged in the hole 5, the top end of the fixed shaft 4 passes through the top plate 1, the bottom end of the fixed shaft 4 is inserted into the bottom plate 2 and rotates relative thereto, The outside of the top plate 1 is provided with a holding mechanism for replacing the tested sample, a motor 7 is arranged above the holding mechanism, the output end of the motor 7 passes through the holding mechanism, and the The output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com