Device for treating breed farm powder polluted air, and using method

A technology for polluting air and powder, applied in separation methods, chemical instruments and methods, using liquid separation agents, etc., to achieve the effect of solving powder pollution and good air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

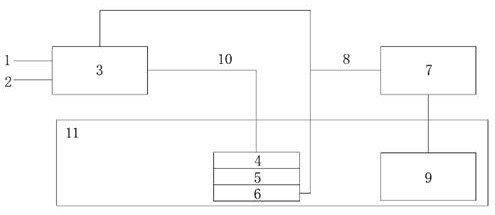

specific Embodiment approach 1

[0022] The device consists of 0.5MPA compressed air 1, 0.3MPA pressure water 2, air-water atomization vortex fluid generation device 3, air-water atomization vortex multi-phase fluid ejector 4, air-water atomization vortex multi-phase Phase fluid 5, powder feeding device 6, control center 7, control signal line 8, powder polluted air state sensor 9, fluid connection pipeline 10 and housing space 11; 0.5MPA compressed air 1 is connected through a separate The pipeline is threadedly connected to the inlet of the pneumatic fluid on the gas-water atomizing vortex fluid generating device 3, and the pressure water 2 of 0.3MPA is connected to the hydrodynamic fluid on the gas-water atomizing vortex fluid generating device 3 through a separate connecting pipeline. The inlet threaded connection, the air-water atomized vortex multiphase fluid 5 generated by the air-water atomized vortex fluid generating device 3, the control center 7, and the air-water atomized vortex fluid generating de...

specific Embodiment approach 2

[0030] The device consists of 0.3MPA compressed air 1, 0.1MPA pressure water 2, air-water atomization vortex fluid generation device 3, air-water atomization vortex multi-phase fluid ejector 4, air-water atomization vortex multi-phase fluid Phase fluid 5, powder feeding device 6, control center 7, control signal line 8, powder polluted air state sensor 9, fluid connection pipeline 10 and housing space 11; 0.3MPA compressed air 1 is connected through a separate The pipeline is threadedly connected to the inlet of the pneumatic fluid on the gas-water atomizing vortex fluid generating device 3, and the pressure water 2 of 0.1MPA is connected to the hydrodynamic fluid on the gas-water atomizing vortex fluid generating device 3 through a separate connecting pipeline. The inlet threaded connection, the air-water atomized vortex multiphase fluid 5 generated by the air-water atomized vortex fluid generating device 3, the control center 7, and the air-water atomized vortex fluid generat...

specific Embodiment approach 3

[0038] The device consists of 0.4MPA compressed air 1, 0.2MPA pressure water 2, air-water atomization vortex fluid generation device 3, air-water atomization vortex multi-phase fluid ejector 4, air-water atomization vortex multi-phase Phase fluid 5, powder feeding device 6, control center 7, control signal line 8, powder polluted air state sensor 9, fluid connection pipeline 10 and housing space 11; 0.4MPA compressed air 1 is connected through a separate The pipeline is threadedly connected with the pneumatic fluid inlet on the gas-water atomizing vortex fluid generating device 3, and the 0.2MPA pressure water 2 is connected to the hydrodynamic fluid on the gas-water atomizing vortex fluid generating device 3 through a separate connecting pipeline. The inlet threaded connection, the air-water atomized vortex multiphase fluid 5 generated by the air-water atomized vortex fluid generating device 3, the control center 7, and the air-water atomized vortex fluid generating device 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com